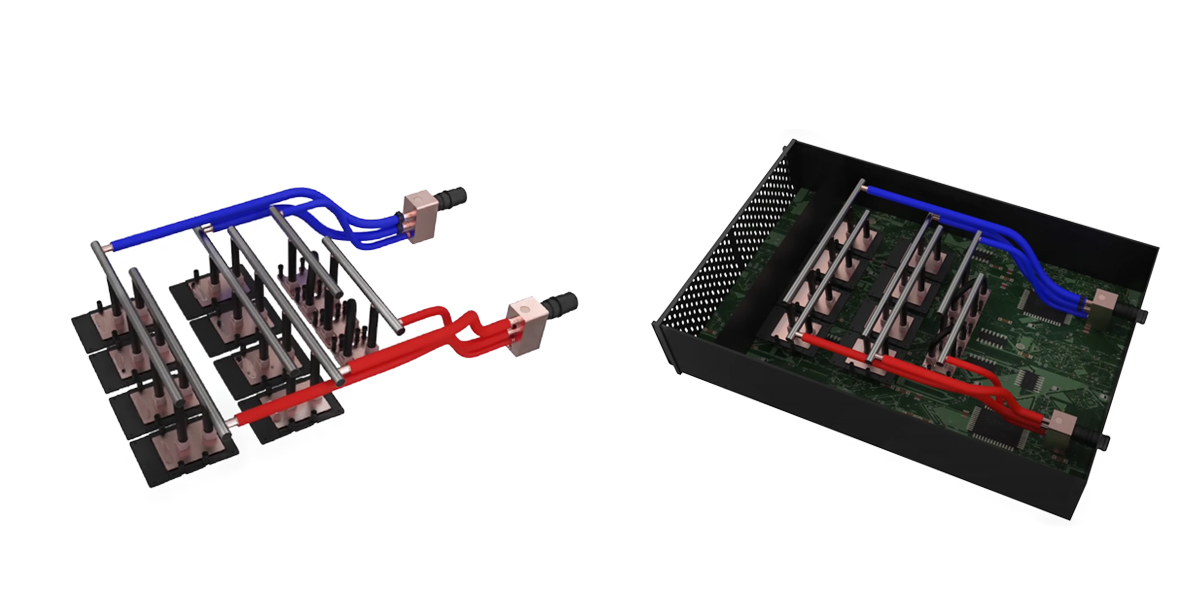

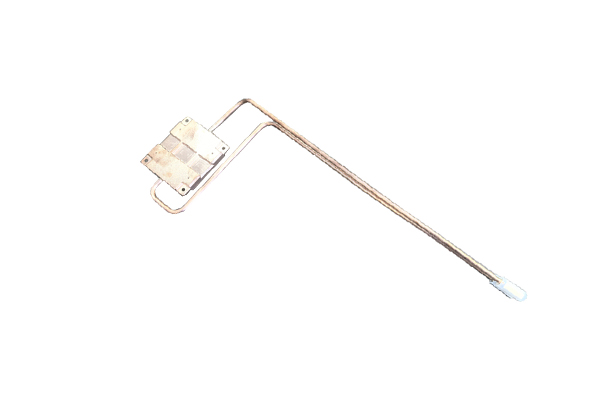

In the new era of rapid development of artificial intelligence and cloud computing, thermal management has become a core element for the stable operation of data centers. Our company has launched the direct to chip liquid cooling loop to meet industry transformation. This AI server cooling solution utilizes a copper plate that directly contacts the chips for cooling, ensuring that heat is quickly conducted and effectively released, allowing CPUs and GPUs to operate continuously at optimal conditions. For AI servers, custom direct to chip cooling significantly enhances server performance, enabling them to easily tackle high-load computing challenges.

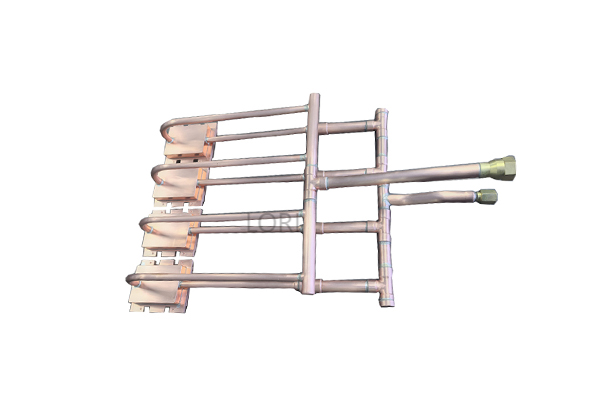

The design of the direct to chip liquid cooling loop is full of innovation. The direct cooling technology using copper plates not only achieves efficient heat dissipation but also simplifies installation and maintenance processes. Additionally, we employ advanced vacuum brazing technology to ensure a tight fit between the cooling plate and the chip, enhancing heat dissipation efficiency and system reliability. With leak-proof guarantees and broad processor compatibility, the direct to chip liquid cooling is the ideal choice for future high-performance computing environments.

By choosing custom direct to chip liquid cooling loop, you are not only improving cooling performance but also laying a solid foundation for the sustainable development of your data center. We invite you to join us in creating efficient, reliable, and intelligent cooling solutions, supporting every breakthrough in your computing efforts and together seizing a leading position in cooling technology!