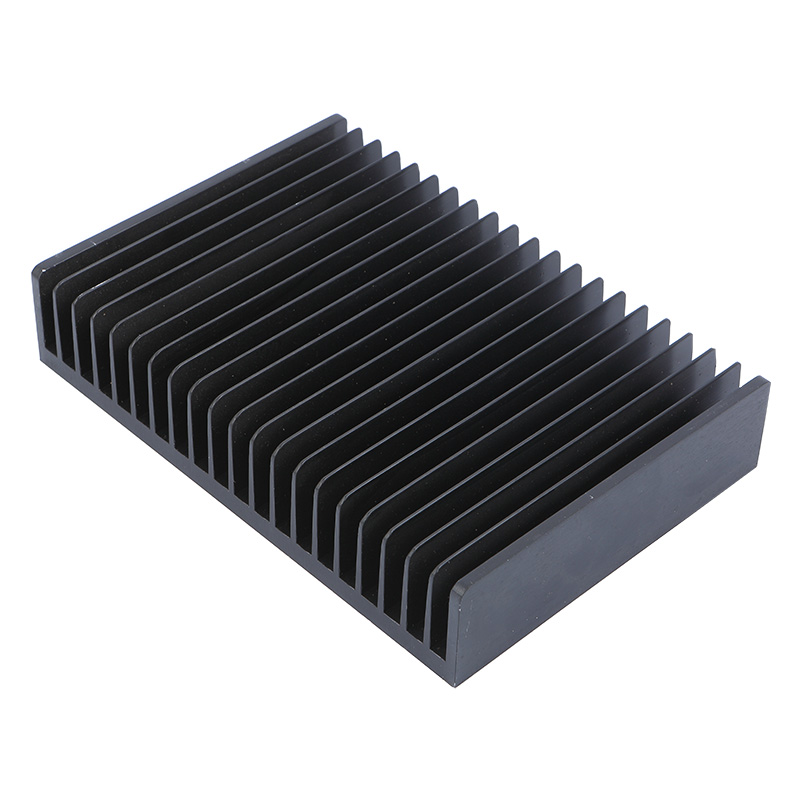

In Lori, passive plate fin heat sinks are usually used on the outside of the mechanical housing and housing. Compared with other cooling methods, the main reasons for using passive plate fin heat sinks are:

1. Fail safe

2. Low maintenance

3. No power

4. No noise

5. Simple production methods

An important limitation is that the fins should be placed vertically. Otherwise, there will be no optimal airflow. About the plate fin heat sink design, we can calculate and analyze the heat sink through simulation test. In order to improve the performance of the heat sink, we can expand the area by increasing the number of heat sink fin, which will increase the possibility of heat transfer from the heat sink to the surrounding air. This optimizes the air flow between the Plate fins.

hat is plate fin heat sink?

hat is plate fin heat sink?