E-mail: sales@lori-cn.com

Mobile phone: +86 13713030144

Wechat: zlc541833696

The Skived fin, also known as skiving technology, simply takes an entire piece of aluminum or copper and use special skived machine to cut out fins with standard spacing and a certain thickness and height. Because of using high precision cutting technology, the integration of the forming, relative to other processing technology, the same volume of raw materials can be cut out more heat dissipation area, the heat transfer performance is more stable, in the same condition,the cooling performance is more than 1.5~2 times of the efficiency of traditional bonded fin or soldering heat sink, thus greatly improve heat dissipation efficiency and extend the service life of heating components.

As one of skived fin heat sink manufacturers, Lori adopts precision skived fins process manufacturing customized copper and aluminum skived fin heat sink. Because it is used the whole cutting forming, heat collection being one piece with the heat dissipation plate, which makes the heat directly from the endothermic base plate to heat collection efficient transmission. It can be in area of cutting out more heat per unit area (compare traditional extrusion process heat dissipation area can be increased by 30% - more than 50%). With its unique production process makes the collection form a smooth and pits to contact with the air of fin area is larger. Thoroughly overcome the traditional welding technology and insert process caused by the thermal resistance of medium, thereby further up the heat conduction efficiency. This skived fin technology made it thinner than traditional and spacing is smaller, which makes the minimum spacing can be as thin as 0.20mm. So as to avoid the accumulation of heat in the heat sink, which allows the heat to take away quickly, thus significantly improving the heat tranfer effect. Skived fin heat sink material can use copper or aluminum, so we can provide copper skived fin heat sink or aluminum skived fin heat sink according client's cooling demand.

-

Vacuum Brazing High Density Copper Skived Fin Microchannel CPU Liquid Cold Plate Heat SinkInquire

-

Lori Custom Skived Fin Heat Sink Microchannel Cold PlateInquire

-

High Power Energy Storage Heat Pipe Skived Fin Heat SinkInquire

-

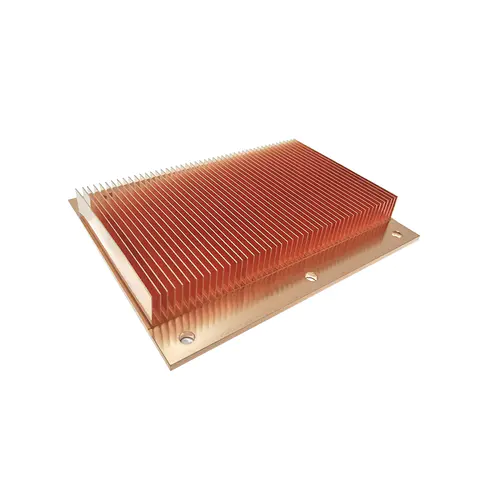

High Power Skived Fin Copper HeatsinkInquire

-

High Performance Custom Medical Laser Aluminum Skived Fin Heat SinkInquire

-

All-solid-state Laser Custom Skiving Fin Heat SinkInquire

-

Custom Skiving Fin Heat Sink For All-solid-state LaserInquire

-

5G Communication Equipment High-Power Copper Tube Customized Aluminum High-Density Skived Fin Large Heat SinkInquire

-

Custom High Fin Density Copper Heat Sink Skiving Manufacturing ProcessInquire

-

Custom Electronic Component Copper Skiving Fin Heat SinkInquire

-

High Power Aluminum Skived Fin Heat Sink For Inverter CoolingInquire

-

Large Copper Heatsink With Skiving Manufacturing ProcessInquire

-

Auminum Skived Fin Heatsinks RadiatorInquire

-

Custom Copper Skiving Heat Sink PlateInquire

-

Skiving Heatsink With HeatpipeInquire

Skived fin heat sink has the following advantages:

1) Perfect conductivity between base and fins. Because skived fin heat sink is a whole profile without any connection point, which can give full play to the heat dissipation characteristics of the heat sink.

2) High-density fins, Lori's skived fin process can make the skived fin more thinner and denser, with higher heat transfer efficiency.

3) Great forced airflow solution, the skived fin processing technology is simpler than other liquid cooled heat sink, with lighter weight and lower cost.

4) Compared with aluminum extrusion and other processes, skived heatsink is less limited in size and can be made wider, which can be used for heat transfer of machines with large power.

5) Customized skived fin heat sink does not need expensive tooling which provides greater design flexibility. Instead, each skived fin is cut separately using the same tool which allows for lower tooling costs.

6) Add a thermal interface material to the skvied fin heatsinks to better connect with your heat source and complete your thermal solution.

Skived fin heat sink are mainly suitable for industries with high thermal density and high power dissipation requirements, which are widely used in power, medical, communication, industrial control and server industries. With the large-scale applications, LORI 's skived fins technique becomes more mature and the coverage of this technique has been increased. With the gradual enhancement of the degree of automation, we demonstrate the apparent advantage from the aspects of cost and reliability. We have received the endorsement from various domestic and overseas customers.