Cold forging is to recrystallization temperature of profile below (generally refers to room temperature) forming processing, forging technology. Cold forging material is mostly below room temperature deformation resistance is lesser, plasticity better aluminum and partial alloy, copper and partial alloy, cold forging can make profile produces work hardening in processing process (strain hardening), can make intensity and hardness increase.Cold forged heat sink is a good choice for casting complex shapes with excellent thermal conductivity. The cold forging process allows an almost perfect straightness of more fins per square millimeter. The shapes of cold forged heat sink include plate fin heat sink, round pin heatsink and oval fin heat sinks.The manufacture of forged heat sinks are well suited to the use of copper because the copper heatsinkcan be shaped without high temperatures and can be formed with minimal damage. Cold forging heatsink manufacturing can often include secondary processing operations such as holes, chamfering and steps to reduce unnecessary waste.Cold forging technology has been widely used by heat sink manufacturers in the production of light source heat sinks and LED heat sinks. LORI is one of the few companies who used cold forging to produce heat sinks in early days and we have accumulated abundant experience of cold forging technology. In addition to the production of heat sinks for typical light sources, LORI has gained experiences in the manufacturing techniques for high power cold forged heat sink. We have resolved the problems such as the low thermal conductivity of die-casting micro-channels and higher costs for machining micro-channels. We have already applied cold forging heatsink to cooling solutions including high-voltage inverters, wind power converters, and electric motor controllers.

-

6W LED Cold Forging Cob Downlight 36*30mm heatsinkInquire

-

Aluminum Cold Forging Led Heat Sink For Plant Grow LightInquire

-

240W High Power Active Cold Forged Cob Heat Sink For Stage Lights Studio LightsInquire

-

LED Street Light Ceiling Stadium Lamps Cold Forged Pin Heat SinkInquire

-

Led Mining Light Patio Light 100 W Cold Forged Aluminum Heat SinkInquire

-

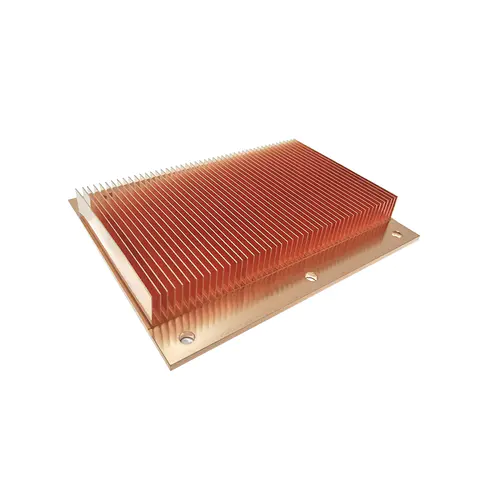

Customized High Power IGBT Cold Forging Copper Heat SinkInquire

-

High Power LED Mining Light Cold Forging Heat SinkInquire

-

Cold Forged Aluminium Round High Power Led HeatsinkInquire

-

Cold Forging Aluminum Heat Sink For Electronic ComponentsInquire

-

Cold Forged Aluminium Oval Toothed Heat Sink For Led LightInquire

-

Cold Forged Aluminium Led Heat Sinks High power 1070 LED LightInquire

-

Custom High Power Large LED Sunflower Cold Forging Heat Sink for LED Street Light CoolingInquire

-

LED Light Cold Forged Aluminum Cob Heat SinkInquire

-

Best Heat Sink Design For Automobile Lamp Cold Forging Heat SinkInquire

-

Cold Forged Aluminum Profile Sunflower High-Density Tooth Cob HeatSink For LED High Power LuminairesInquire