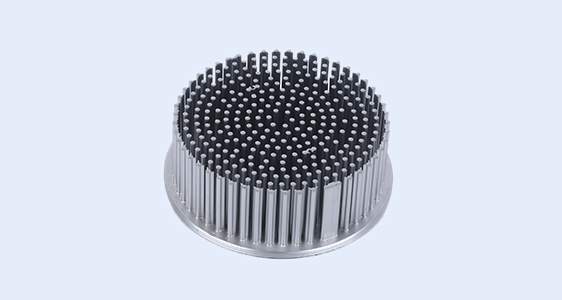

Cold Forging Pin Heat Sink For Cob Led Heatsink

Pin heat sink also belong to cold forging heat sink, which has good mechanical properties, high productivity and high material utilization; and is particularly suitable for mass production, thus reducing the production cost.

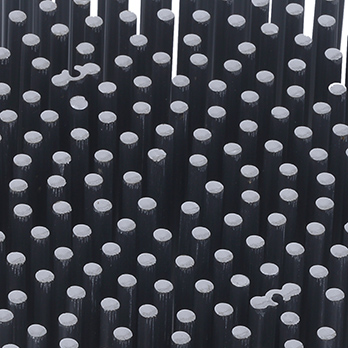

In addition, the heat resistance of the heat sink is good, The low thermal resistance and high thermal effects. This can be assured of the transfer of heat in a satisfied stylish so as to achieve the ultimate cooling effect.

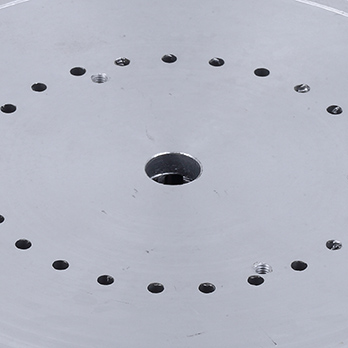

This pin heatsink have better mechanical performance, higher throughput and higher material utilization rate. and cost saving

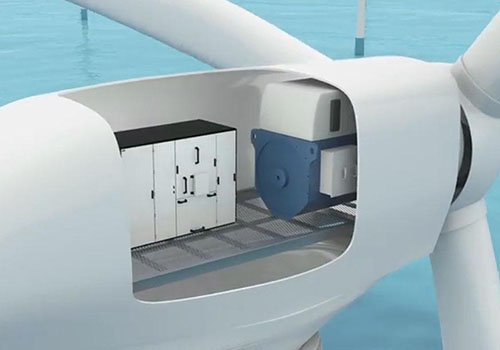

Applications to Cob Led Heatsink, high-voltage inverters, wind power converters, and electric motor controllers.