When we hear folding, most of the time, we don't initially consider folded fin heat sink. We first think of folding typical daily items like laundry or paper. Most of us don't think or know that folding has great technical applications. Science, technology and engineering have used folding as a resource for innovation in a variety of fields. Material innovations that increase the strength or flexibility of individual material plates stem from folding research. Folding improves the storage of airbags for vehicles or solar arrays for space applications. Foldable batteries, circuits and foldable robot forms are pushing the use of electronics and robotics.

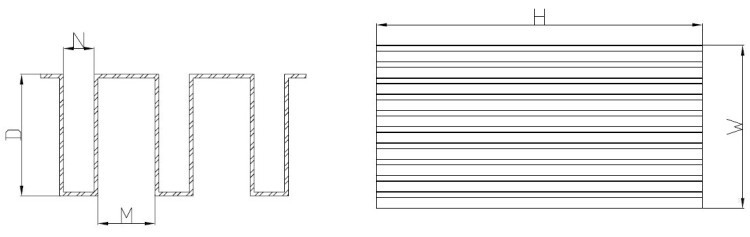

Lori is folded fin heat sink manufacturers, can apply folded fin technology in thermal management. In the field of thermal management, folded fin allows us to increase the surface area within a given volume. Surface area is critical for effective heat transfer. Single piece folded fin also minimize the number of components used to assemble heat transfer assemblies, such as folded fin heat sinks or larger heat exchangers. Because the folded fin heat sink stack is made of a single piece of material, it can reduces machine set up time, assembly and processing time, and scrap material.