The zipper fin is stamped from metal sheet step by step. Firstly, use the punch to create the geometry of the fin. Length, height and fin pitch are determined in the first set of punches. The fin thickness is determined by the thickness of the fin used. In the process of secondary punching, the fin is folded up and locked together with the previous fin. When the fin stack has enough fins for the application of the stack, it will be removed from the punching area and then wave soldered/bonded to a metal base to form a zipper fin heat sink. For example, a copper base can be used with aluminum zipper fins to ensure thermal performance and effective heat dissipation, but at a much lighter weight than a standard copper heatsink. Lori's zipper fin heat sink is the right choice because they were designed with high aspect ratio fin heat sink profiles, enabling taller, thinner and more densely fin heat sink for increased surface area and improved cooling performance. so zipper fin heat sink is also called high performance heat sink.

In addition, Zipper fin heat sink with heat pipe is made by continuous mode, and the heat pipe is connected by interpenetration, embedding, bridge, etc. Zipper fin heat sink can be customized with heat pipes and integral ducts to enhance thermal performance, By taking advantage of the high thermal conductivity of the heat pipe and the high density of the zipper fin, the heat dissipates rapidly and meets the application requirements of small space and high heat density. particularly with active heat sink for air movers, fans, and blowers. Heat pipe is a common addition to zipper fin heat sink, because the heat sink base acts as the evaporator section and the heat sink fins as the condenser section. This provides a lightweight, high performance option with only a one-time tooling cost for production.

Zipper fin heat sink is widely used, from ordinary PC, graphics card, server, telecom equipment, industrial control equipment. The thinnest fin of the fin is 0.2mm, the height is 200mm, and the gap is 1.0mm. It is very suitable for the cooling of the fan with the system. We can customized zipper fin heat sink for you, but also we can provied you customized stacked fin heat sink, folded fin heat sink, and etc, please contact us!

-

High Power LED Zipper Fin Heat Sink with Copper PipeInquire

-

1U Zipper Fin Heat Sink For Intel CPU LGA2011/115XInquire

-

Customized Zipper Fin Heat Sink With Soldering Heat Pipe LORIAluminum zipper fin heat sinkInquire

-

Round Aluminum Zipper Fin Heatsinks for LED lightZipper fins are created using a set of individually stamped fins which are folded into shape with interlocking groovesInquire

-

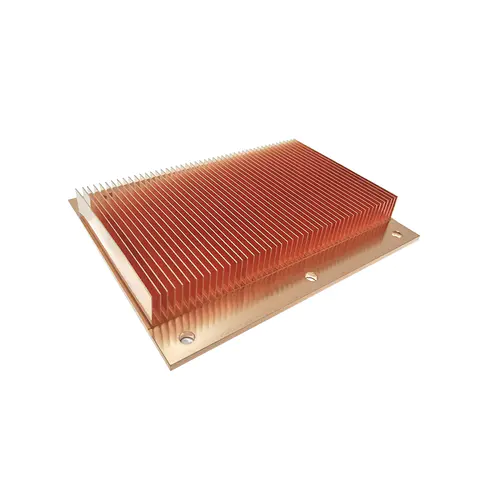

Copper And Aluminum Stamped Zipper Fins Heat SinkZipper fins are copper or aluminum fin and it is possible to mix the different materials baseInquire

-

Zipper Fin Heat Sink For Laptop LoriInquire

-

Aluminum Zipper Fin Stack Fin Heat SinkZipper fins are made of aluminum material and soldring on aluminum baseInquire

-

Zipper Fin Heat Sink For LED HeatsinksRound Zipper fins are made of aluminum material and soldring on aluminum baseInquire

Zipper Fin Heat Sink Features & Benefits.

1. Pre-Tooled to reduce time to production

2. Stamped from thin sheet metal

3. Made from copper or aluminum material

4. High aspect fin ratio designs can realize densely packed fin count

5. No minimum order quantity (MOQ), Rapid prototype

6. Can be customized with copper plate, heat pipe, or vapor chamber to enhance heat transfer