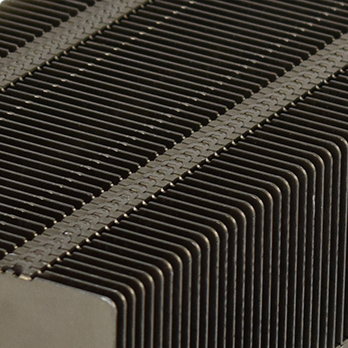

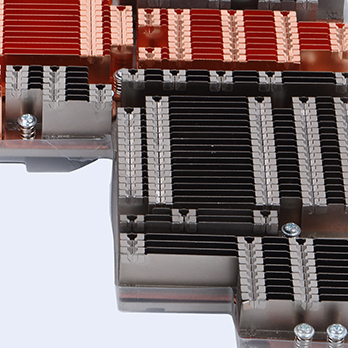

For customers with electronics production requirements that require innovative and cost-effective approaches to a variety of thermal application designs, using of stamped fin heat sink is often the best option. Taking the advantage of stamping fin technology, manufacturers of these devices are able to configure the heatsink fins in a variety of shapes and sizes. These stamped fin heat sinks are made of copper and aluminium, which are the most common heat sink materials, and the aluminium stamped fin heat sinks are usually made of AL6063 aluminium alloy, which produces a high thermal conductivity of about 200 W/(mK). Copper stamping fin heat sinks are usually manufactured using the C1100, which produces thermal conductivity up to ~ 400 W/(mK). Not only can these heat sink be manufactured with extremely light weight, but also they can be used for medium to high capacity operations. By far, one of the best features is its extreme efficiency, which makes it ideal for the smallest size of packaging.