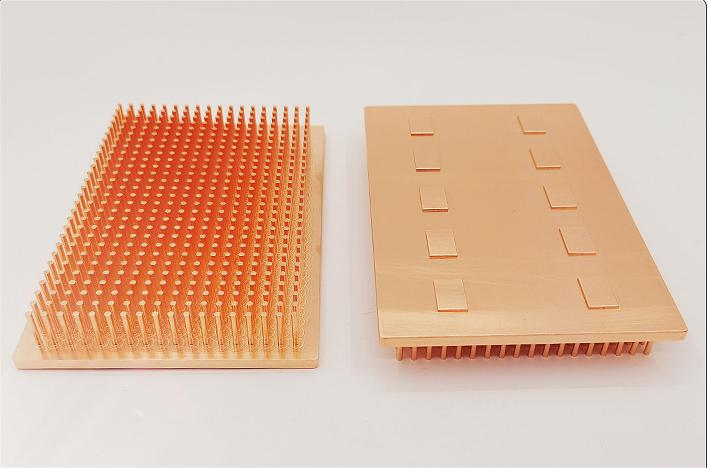

Customized High Power IGBT Cold Forging Copper Heat Sink

IGBT Cold Forging Copper Heat Sink has good mechanical properties, high productivity and high material utilization; and our high power igbt cold forging heat sink is particularly suitable for mass production, thus reducing the production cost.

1.Selected Material: Choose pure copper as thermal conductivity base material

2.Oxidation Treatment: Pure copper heat sink generally adopts toning treatment, exquisite appearance and corrosion resistance

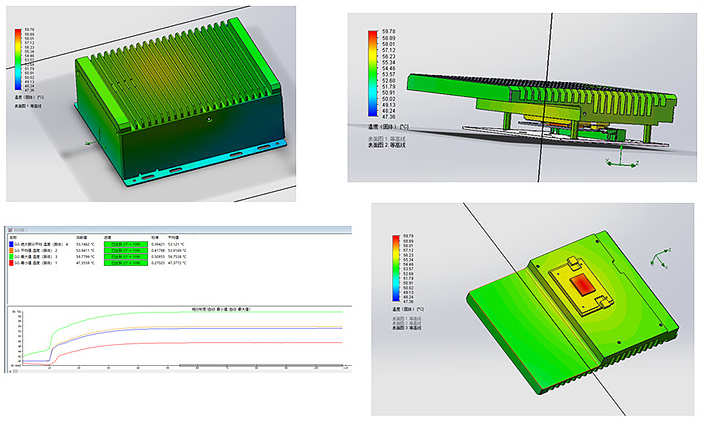

3.Professional Design: Professional design team simulates thermal performance in advance to minimize cold forging heat sink weight and maximize heat dissipation efficiency

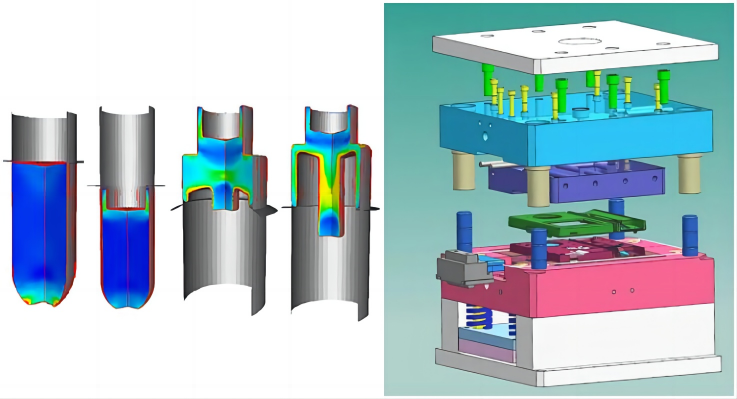

4.Non-standard Customization: Integrate mold manufacturing, heat sink design, and production to meet various needs with complete specifications.

Lori is a professional cold forged heat sink manufacturer, we can provide your customized IGBT cold forging copper heat sink according your drawing.