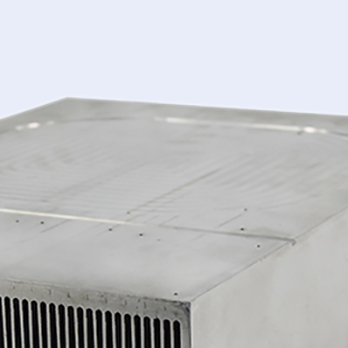

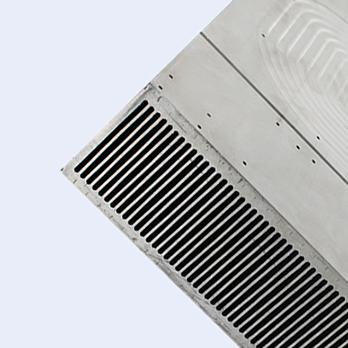

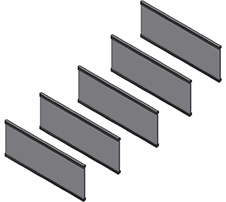

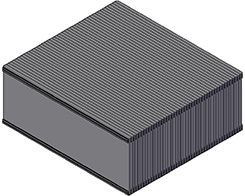

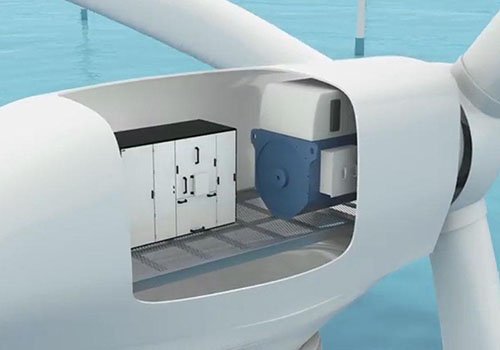

Stacked fin heat sinks have advantages such as increasing cooling area while forming a closed passage at the same time so as to achieve higher thermal performance, no restriction on it volume, higher strength, lower manufacturing cost, easier installation and maintenance, longer service life, etc. Via our technical innovations, Lori has mastered the technique of re-stacking aluminum extrusions for the production of high power heat sinks. We have several mature production lines for stacked heat sinks and have acquired the endorsement from Israel's military enterprises since we manufactured several batches of large stacked fin heat sinks.