| Place of Origin: | Shenzhen, China (Mainland) | OEM: | Yes |

| Process: | CNC machining,Epoxy Bonding | Temper: | T3-T8 |

| Material: | Copper tube + Cold plate | Shape: | Square |

| Packing: | Standing Export Packing

| Brand Name:

| LORI

|

| Application: | Eletronic Equipment | Certificate: | ISO 9001:2008,ISO 14001:2004 |

| Model Number: | LR0601 | Tolerance:

| 0.01 mm |

| Finish: | Clean+Anti-Oxidant | Quality control: | 100% thermal test |

| Extra process: | CNC Machining | Size: | Custom size |

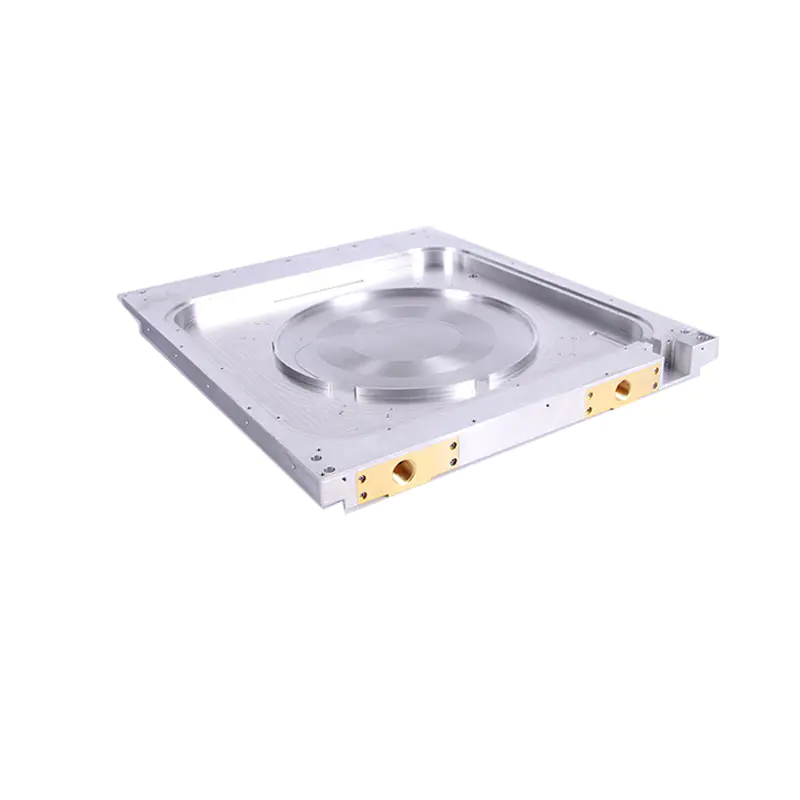

| Applied Field: | New energy automobile , UPS and energy storage system , large server, large pv inverter , SVG/SVC , etc |

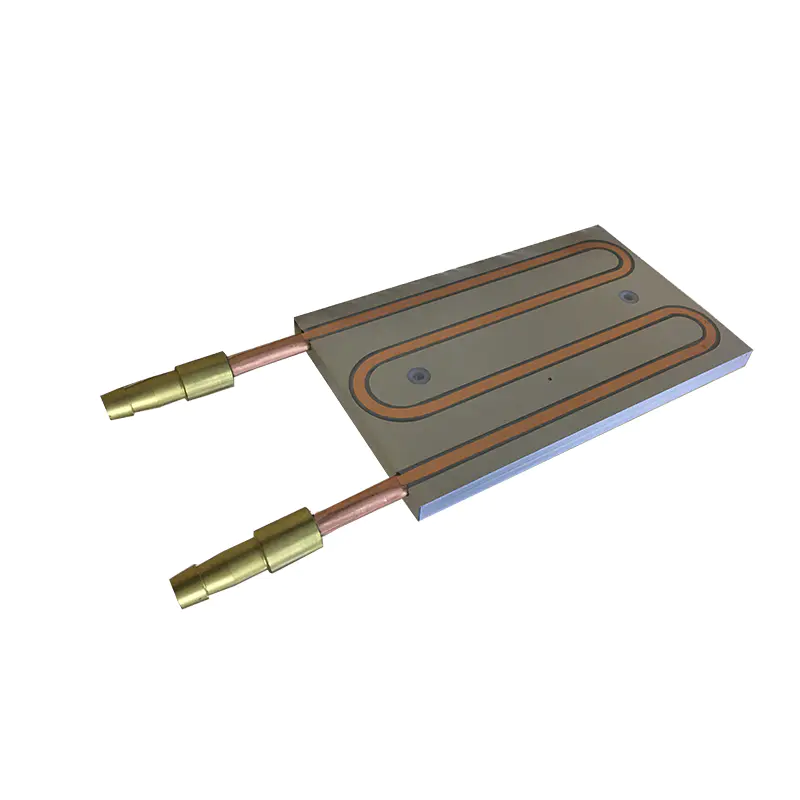

Lori Custom Aluminum Liquid Cold Plate with Copper Tube

Lori aluminum liquid cold plate is through the structure of compact and relatively thin plate-like, strip metal internal layout of the fluid channel, so that the fluid and liquid cold plate between the convection heat transfer, thereby dissipating the surface of the liquid cold plate high power electronic equipment components of the thermal power consumption. The application advantage of electric liquid cooling plate depends on, unit area can dissipate more quantity of heat, consequently heat sink structure can miniaturize. The liquid cold plate for electronic equipment is designed to maintain the low temperature required by the internal components through continuous liquid heat exchange through direct contact with the copper pipe. At the same time, the copper tube of good welding, excellent sealing performance, so that customers less worry about leakage.

Welcome customers to custom all kinds of liquid cooling cold plate design and manufacturing.

for your cold plate liquid cooling. We are an expert on liquid cooling cold plate design and manufacturing and our copper tube liquid cooling cold plate

manufacturing details are as follows:

1. D9/10.5/12.5mm Copper tube can be used.

2. Using epoxy resin to bond the contact copper tube.

3. The use of copper tubes can prevent corrosion of the flow channel.

4. Copper tube of different length and diameter can be customized according to customer requirements.

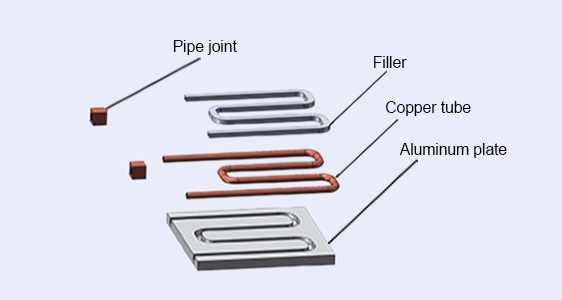

The copper tube on this liquid cooling cold plate is used full buride tube techique. let us introduce what is full buride tube techique for cold plate liquid cooling, please see the following introduction.

Full-buried-tube technique: The filler is a type of highly conductive epoxy resin which is imported from the US. When the temperature difference between two sides of a device is not critical, the liquid cooled heatsink can be applied to either just one side or both sides of the device. Since the copper tube thickness is not affected by any secondary machining and the application safety is ensured due to the protection of the filler, this technique is especially suitable for copper cooling plate applications which use refrigerant as the medium of cold plate liquid cooling .

The techniques for the liquid cooling cold plate include the exposed tube technique, half buried tube techniques, sandwiched tube technique.

Meanwhile, Lori as a liquid cooling cold plate design manufacturer, we also have passed ISO9001:2015, ISO14001:2015, Rohs certification, have enough ability to provide customer with high quality custom liquid cooling cold plate design and Large-scale production capacity.

◪ In order to ensure the best service to the customer , we have formulated this after-sales service system, the company solemnly to the users of after-sales service work to do the following commitment:

◪ 1.Provide online technical support for customers, and provide consulting services on related issues

◪ 2.From the date of spontaneous delivery, if there is any quality problem or quality objection to our company's customized products, please contact with us in time. After checking and coordinating, we can return and replace the products in time.