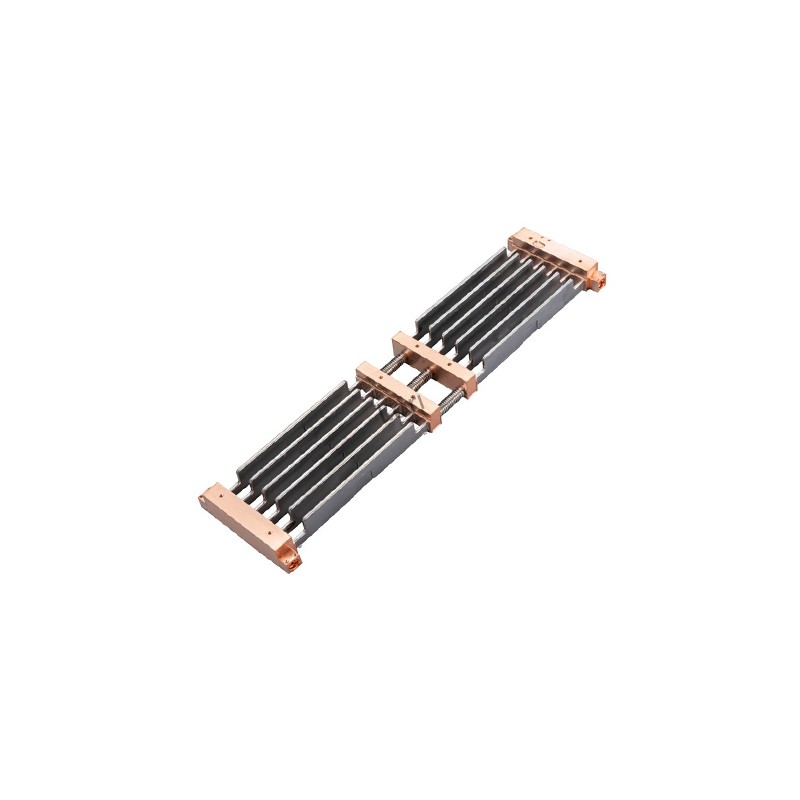

Stainless Steel and Copper Server DIMM Memory Liquid Cooling Cold Plate.

The server memory DIMM liquid cooling cold plate is made of stainless steel tube, corrugated stainless steel tube, and copper block material combined with advanced vacuum brazing process. The precision-designed micro-channel structure optimizes coolant flow efficiency, while the fully sealed vacuum brazed structure eliminates the risk of leakage. Lori stamped stainless steel tube construction of DIMM cold plate allows for greater geometric flexibility. Technicians no longer need to worry about removing the DIMM memory cooling solution to replace each DIMM.

High-frequency trading servers

High-frequency trading servers Edge computer nodes

Edge computer nodes Hyperscale data centers

Hyperscale data centers Cryptocurrency mining

Cryptocurrency mining