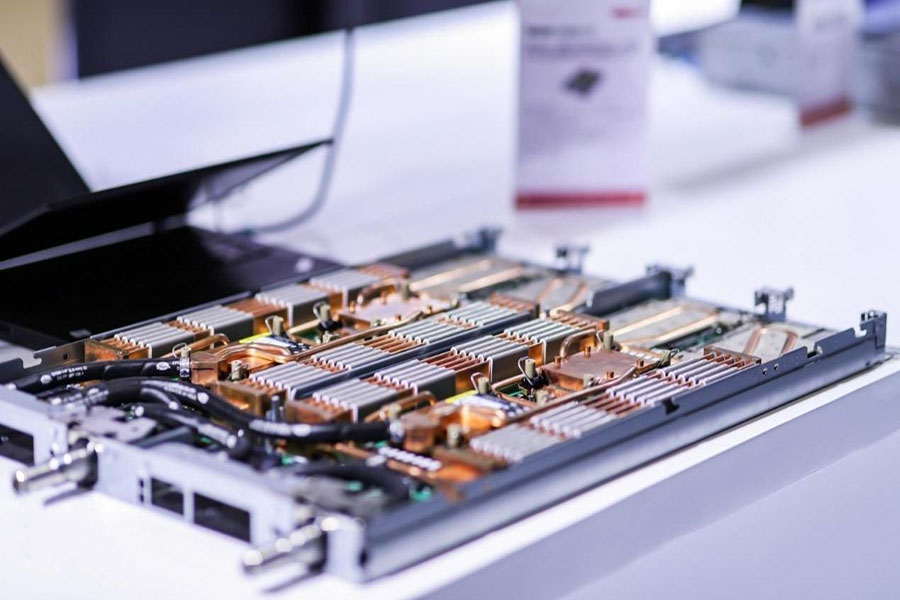

Copper Double Cold Plate Server Liquid Cooling Loop

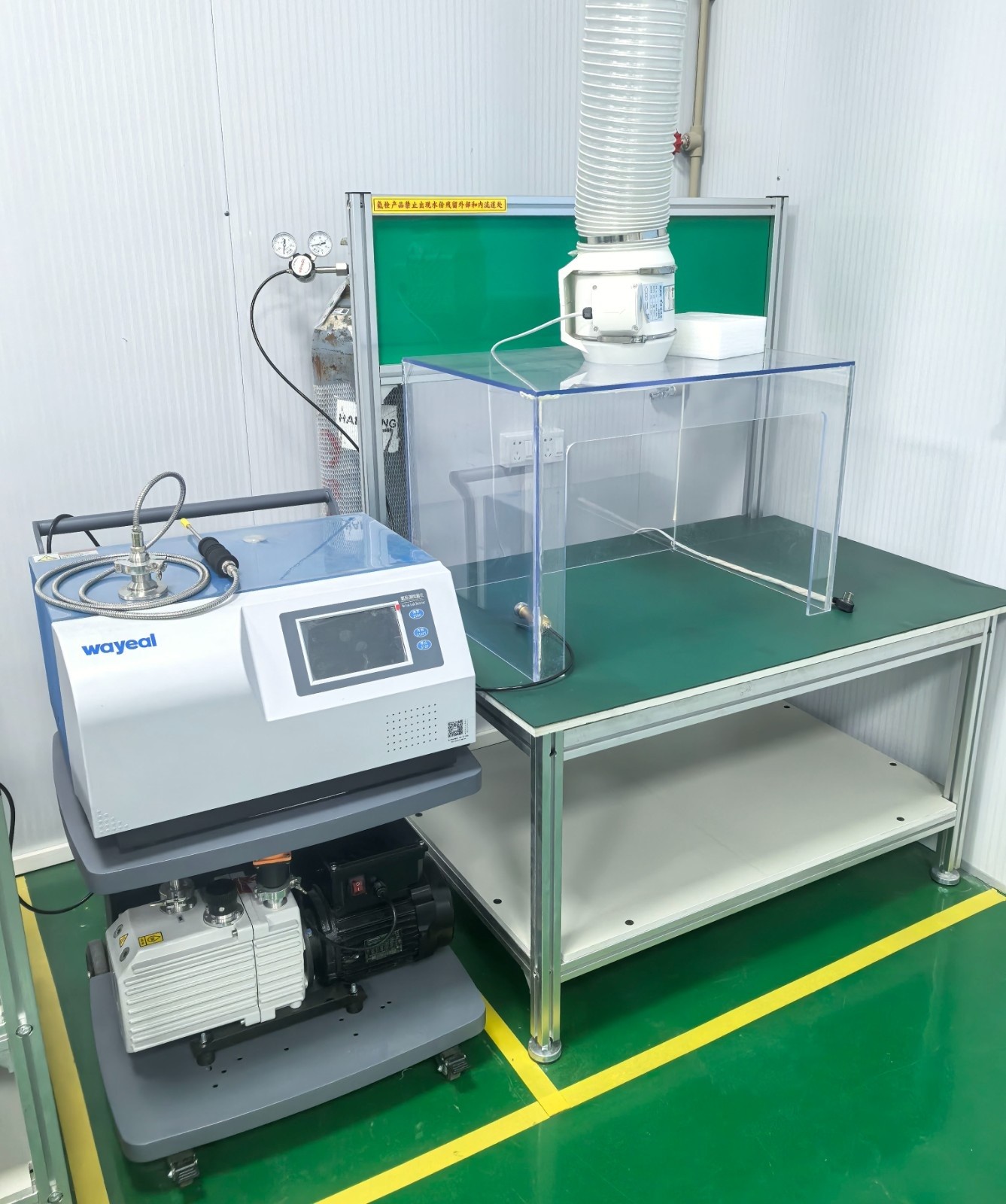

The direct liquid cooling system is made of C1100/C1220 high-purity, high-quality copper with good thermal conductivity and corrosion resistance, suitable for long-time, high-intensity work. The two cold plates, piping, joints and other components are processed into a copper liquid cooling loop by a continuous furnace vacuum brazing process, which enhances the strength and sealing of the welds. Ultra-thin microchannel cold plates and compact liquid cooling loops take up little space in the server rack and are suitable for 1U server racks. The tensile strength of this vacuum brazed liquid cooling loop is 340-390N/mm², which provides good durability and structural stability under high-pressure environments. Lori's custom liquid cooling loops have excellent thermal conductivity, which effectively reduces the temperatures of the CPU and other core components and ensures the stability of the server's working environment.