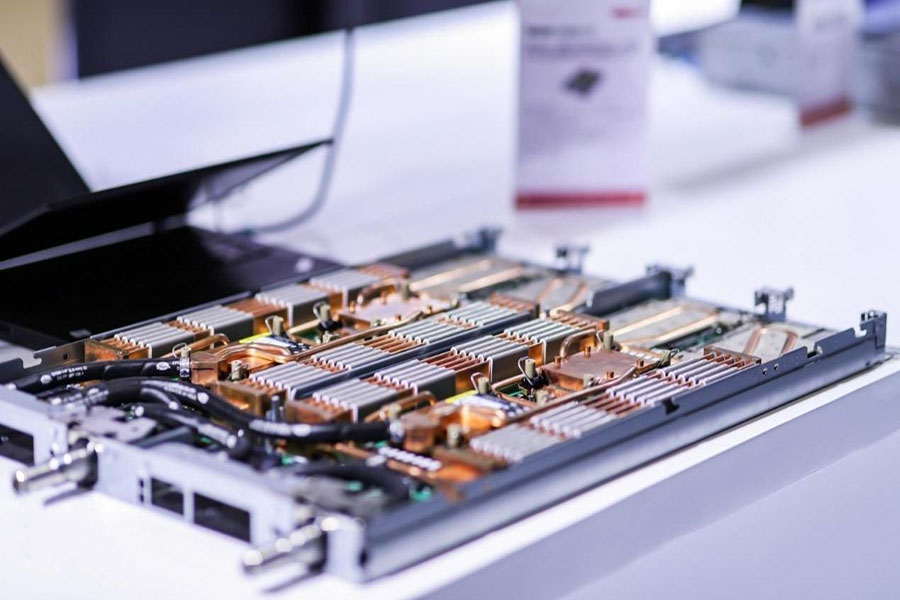

NVIDIA GB200 Custom Liquid Cold Plate Loops

An efficient thermal solution specifically engineered for NVIDIA's GB200

superchip, ensuring optimal performance and exceptional energy efficiency

under extreme workloads.

Core Features:

High-Efficiency Thermal Design: Features a high-density skiving fin array that significantly increases heat dissipation surface area, enabling rapid and uniform heat removal for outstanding cooling performance.

Convenient Installation & Maintenance:Unique floating copper tube design enables adaptive micro-adjustment for quick, stress-free assembly and enhanced serviceability.

Monolithic Construction:Critical components are integrally brazed toeliminate leakage risks, ensuring robust structure and high reliability during prolonged heavy-duty operation.

Premium Thermal Conductivity Materials: Primary contact surfaces utilize high-thermal-conductivity pure copper (Cu1100) material, ensuring unimpeded, efficient heat transfer from the chip surface to the coolant.

This liquid cooling plate loops serve as the critical infrastructure supporting the GB200's computational density and performance release, providing stable and reliable thermal management for data centers and artificial intelligence clusters.