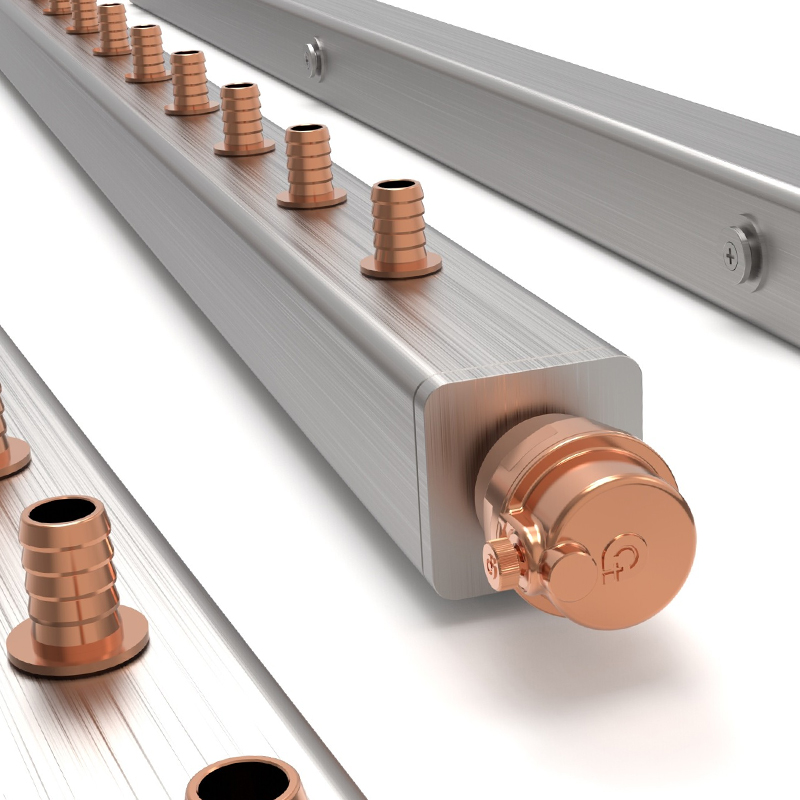

Data Center Liquid Cooling System Custom Rack Manifold

Engineered for flexibility, scalability, and efficiency, this rack manifold

integrates seamlessly into your existing or new cooling infrastructure,

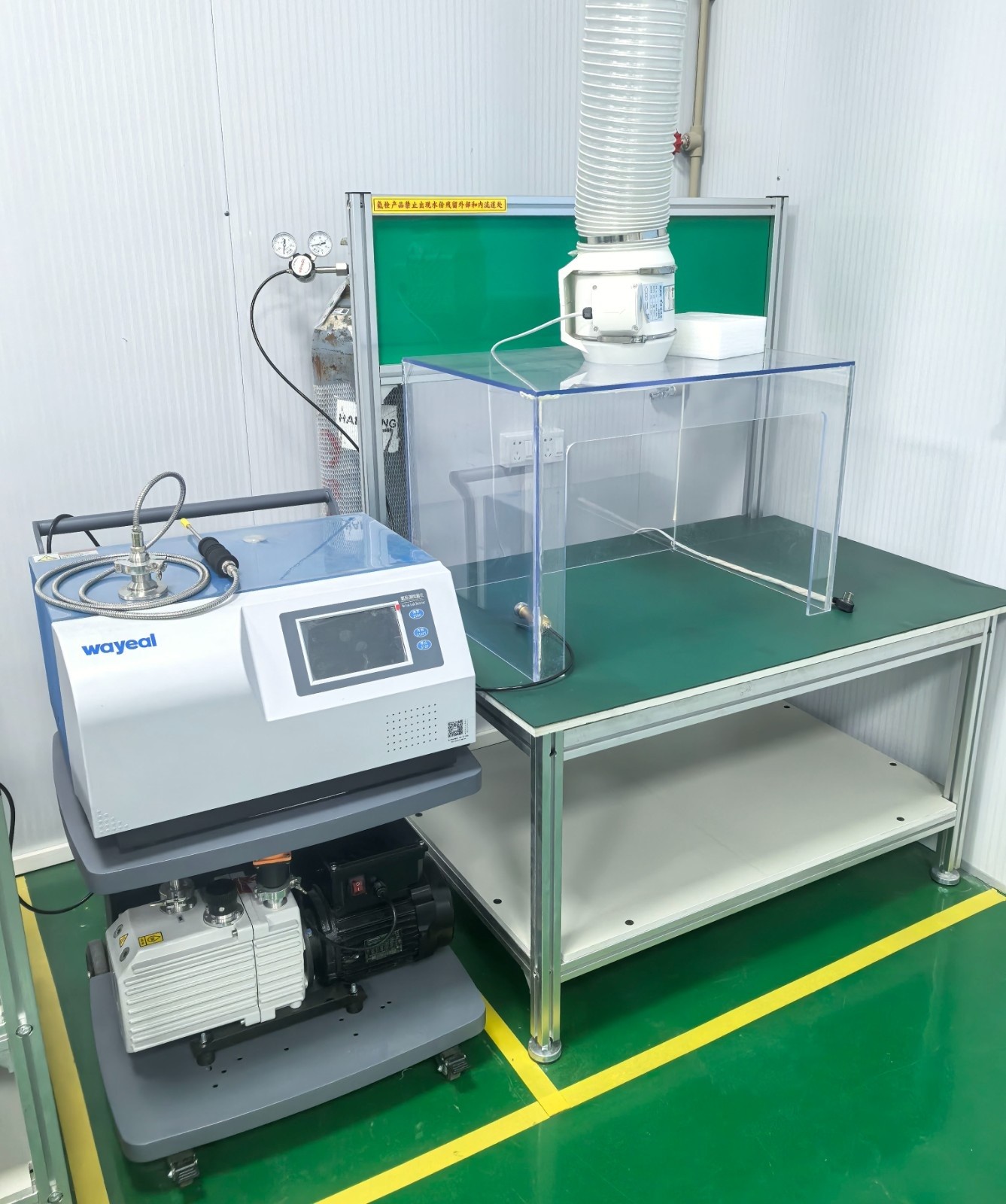

ensuring optimal heat dissipation and operational stability. The vacuum

brazing process ensures that each solder joint of the frame manifold is free

of pores and cracks, reducing the risk of liquid leakage.

Key Features:

1. Customizable Design: Tailored to fit specific rack layouts and cooling

requirements, supporting a variety of tube connections and port configurations.

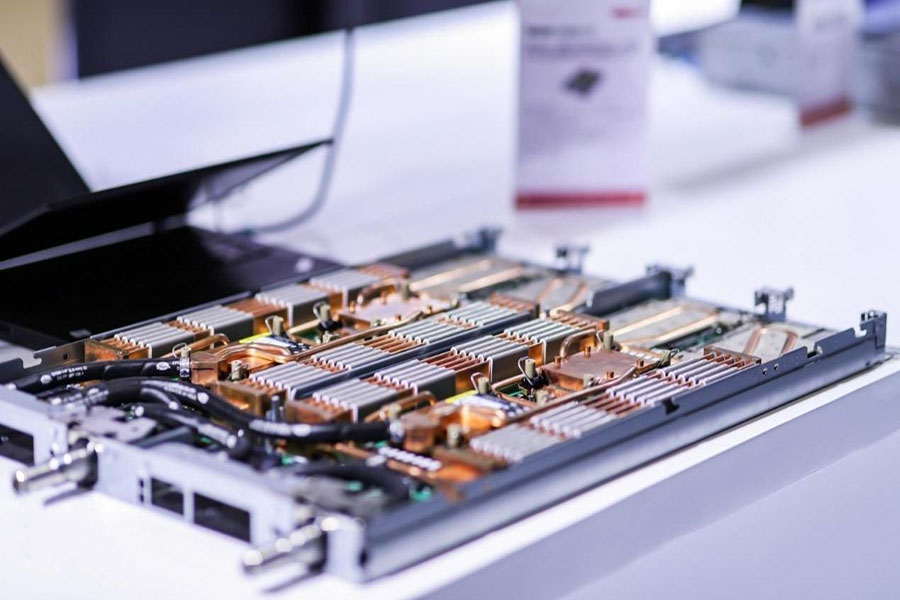

2. High-Efficiency Cooling: Enables uniform coolant distribution across multiple

servers, reducing hot spots and improving overall thermal performance.

3. Durable & Leak-Resistant Construction: Manufactured from robust,

corrosion-resistant materials to ensure long-term reliability under continuous

operation.

4. Easy Integration: Compatible with most liquid cooling systems and

designed for straightforward installation and maintenance.

5. Scalable Architecture: Supports expansion and reconfiguration as your

data center grows or evolves.