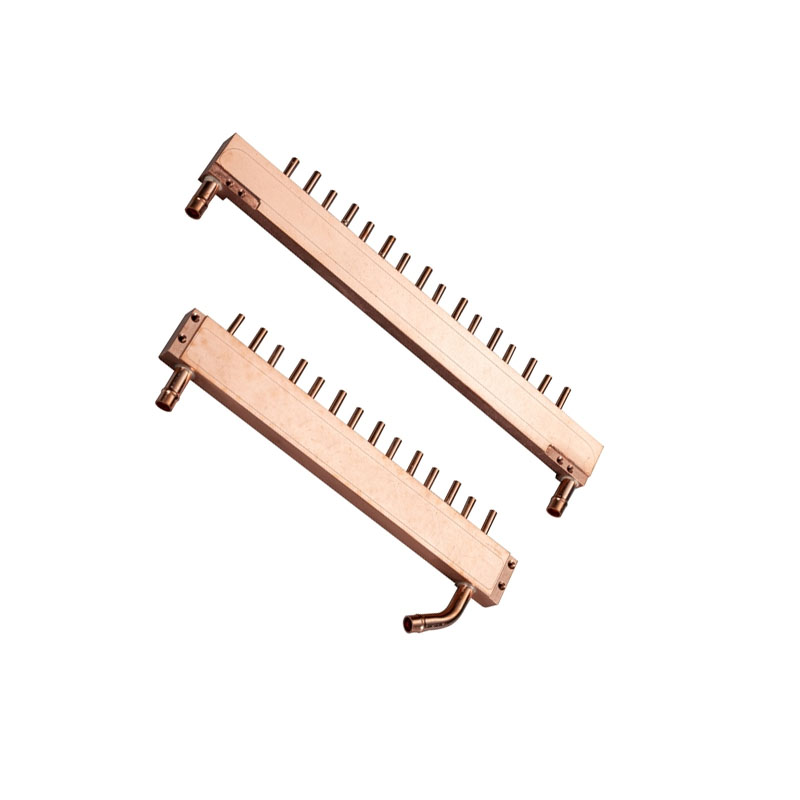

Rack Copper Manifold for Liquid Server Cooling Loop

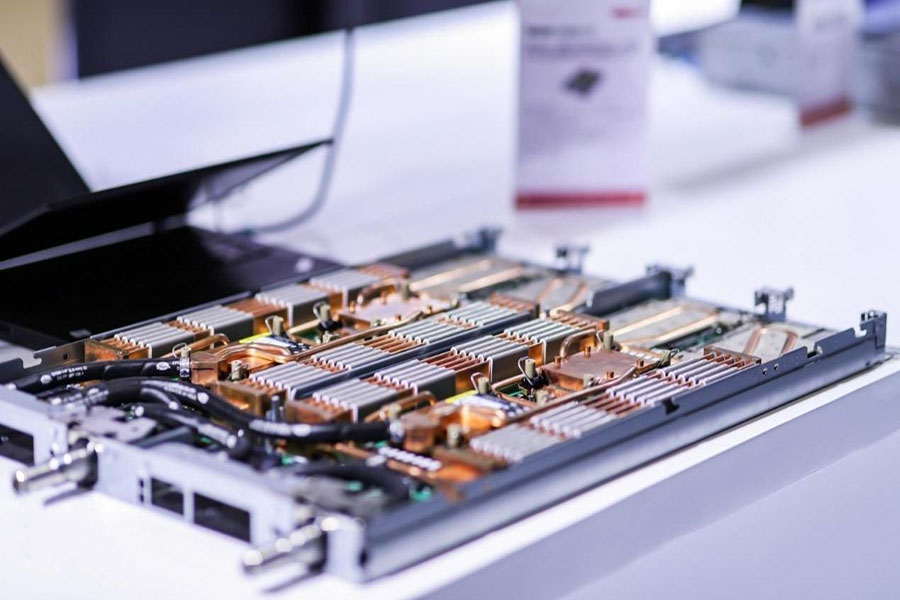

The copper manifold is made of C1100/1220 high-purity copper, which ensures that the server liquid cooling loop system is able to stably and efficiently transfer heat away from all key server components under prolonged periods of high loads and frequent temperature changes to ensure the stable operation of the equipment. The vacuum brazing process ensures that each solder joint of the rack manifold is free of air holes and cracks, reducing the risk of liquid leakage. This increases the safety of the direct liquid cooling loop and extends its service life. The copper rack manifold can be manually connected and flexibly arranged vertically or horizontally within the rack to provide an interface between the cold plate loop in the server and the CDU.