Lori Custom Aluminum Cold Plate Liquid Cooling Loops

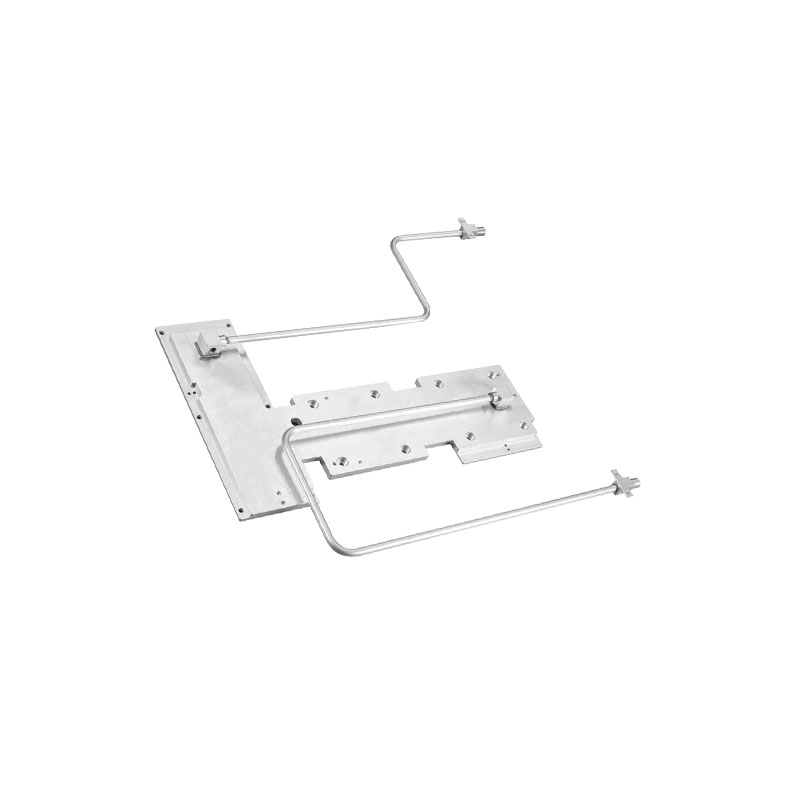

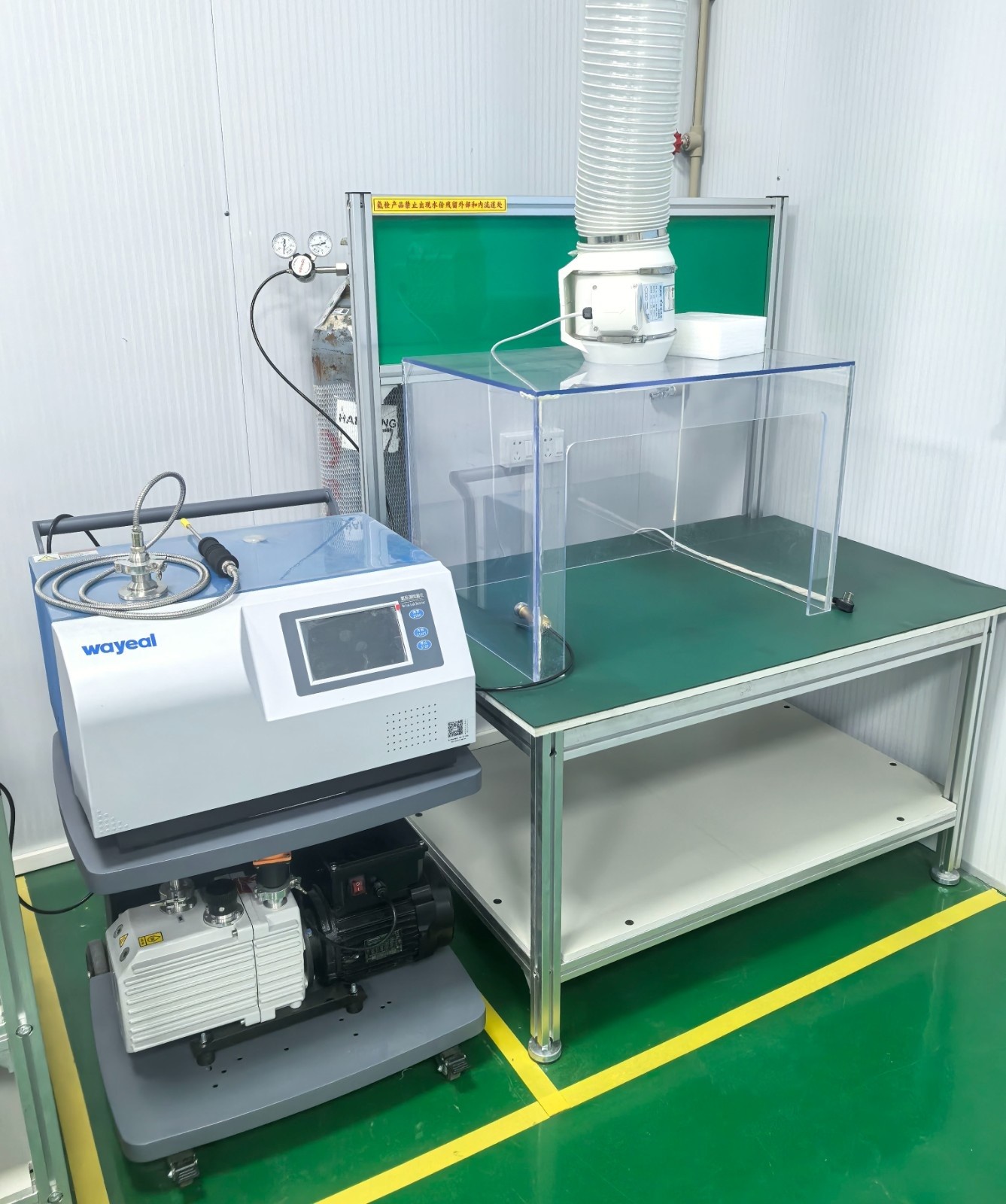

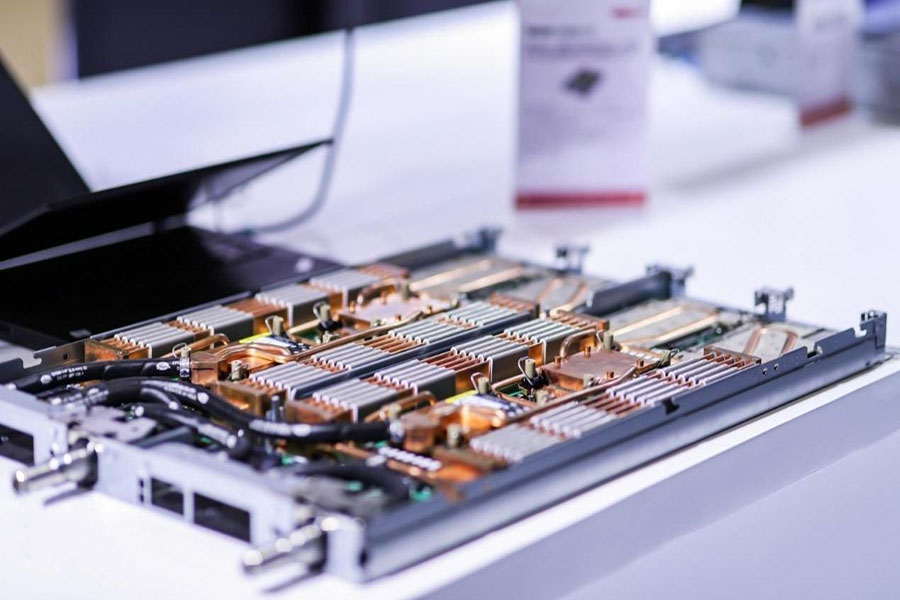

The direct to chip liquid cooling system is made of AL3003 aluminum with excellent thermal conductivity and lightweight characteristics, which is suitable for applications in data centers, supercomputing and high-performance computing environments. The tensile strength of the product is 80-92N/mm², with high structural stability, and the surface is treated with anti-oxidation, ensuring that it can maintain excellent performance under high temperature and long-term use. The cold plate, piping, joints and other components are processed into a aluminum liquid cooling loop by a continuous furnace vacuum brazing process or flame brazing, which enhances the strength and sealing of the welds. Lori's customized liquid cooling loops have excellent thermal conductivity, which effectively reduces the temperatures of the CPU and other core components and ensures the stability of the server's working environment.