| Item | Specification |

| Machine Dimensions | L2000 * W2600 * H2000 mm |

| Material Rack Dimension | L2000 * W620 * H880 mm 2 sets |

| Cutting Height | 150 mm |

| Total Cutting Width | 600 mm |

| Feeding Length | 390 mm |

| Cutting Length Accuracy | ±0.1mm |

| Cutting Perpendicularity | ±0.1mm |

| Main Motor | 380V 7.5KW |

| Oil Pump Motor/Oil Pump | 380V 0.75KW/VP-20 |

| Pump Motor |

|

| Cutter Feed/Feed Drive Servo Motor | 10 meter/min |

| Nose Stepper Motor | 220V 1KW |

| Spindle/Cutting Feed/Feed/Head Bearing | 6207/6205/6005/7205 SKF |

| Cutting Feed/Feed/Head screw | 3205-840mm/3205-680mm/3205-290mm TBI |

| Cutting Feed/Head/Front Clamp Precision Wire Rails | HG30/HG30/EG20 |

| Overall Weight (approx) | 2.1 tons |

| Leadtime | 30 days |

| Operation Function Description | Intelligent, data input, man-machine interface of fin skiving, automatic control processing can be realized by simple data input. |

| Warranty Period | One year (man-made damage, accessories will be charged separately). |

| Contact Information | sales@lori-cn.com +86 17775668621 |

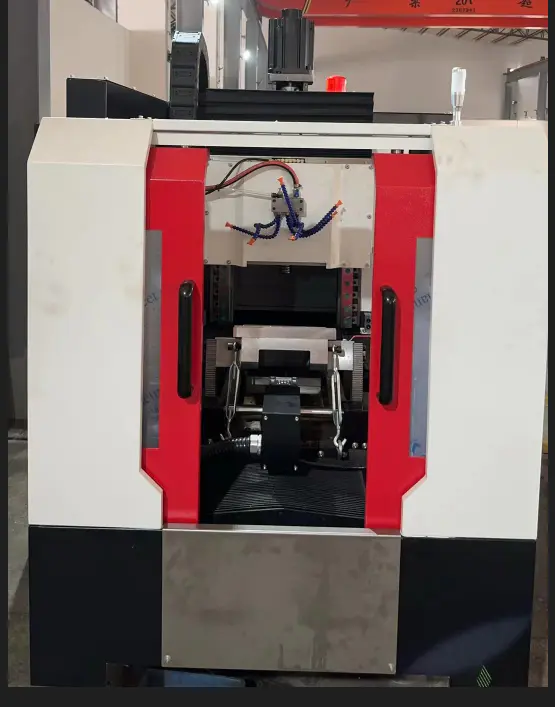

Lori High precision CNC Automatic Gear Hobbing Machine

Lori CNC hobbing machine has the characteristics of high efficiency, precision and flexibility, simple operation.It can process the fins of the skived heat sink, and also can process various types of gear (including spur gear, helical gear, worm gear, etc.), suitable for automotive, aerospace, machinery manufacturing and other industries. The gear hobbing machine is equipped with advanced CNC control technology to ensure smooth operation and increase productivity.

Main features

·High precision: Equipped with high precision spindle and advanced CNC control system to ensure the accuracy of each process.

·Automated operation: Fully automated gear cutting process, reduce manual intervention, improve production efficiency.

·Wide compatibility: can handle a variety of materials including steel, aluminum alloy, etc., suitable for various industries.

·User-friendly interface: Intuitive control panel that allows operators to easily program and monitor machines.

·Durability and reliability: The use of high-quality components and materials to ensure long-term stable operation of the equipment.

Numerical control operation: Intelligent numerical control operation, simple operation, easy to use.

Oil pump motor: automatic oil filling system, more convenient maintenance.

Scram switch: Scram switch design to prevent accidents.

Thickened fuselage: The whole fuselage is vacuum cast, durable and reliable.

1. Q: What is gear hobbing process?

- A: Gear hobbing process is a mechanical process for cutting skived heat sink and high-precision gears, using a special tool (hob) to cut the workpiece.

2.Q: How to maintain CNC automatic gear hobbing machine?

- A:Regular maintenance includes checking the oil level, cleaning the machine, checking the wear of the cutting tools, etc.

3. Q: What types of gears can the CNC machine process?

- A:The machine can produce many types of gears, including spur, helical and worm gears, depending on the application requirements.

◪ In order to ensure the best service to the customer , we have formulated this after-sales service system, the company solemnly to the users of after-sales service work to do the following commitment:

◪ 1.Provide online technical support for customers, and provide consulting services on related issues

◪ 2.From the date of spontaneous delivery, if there is any quality problem or quality objection to our company's customized products, please contact with us in time. After checking and coordinating, we can return and replace the products in time.