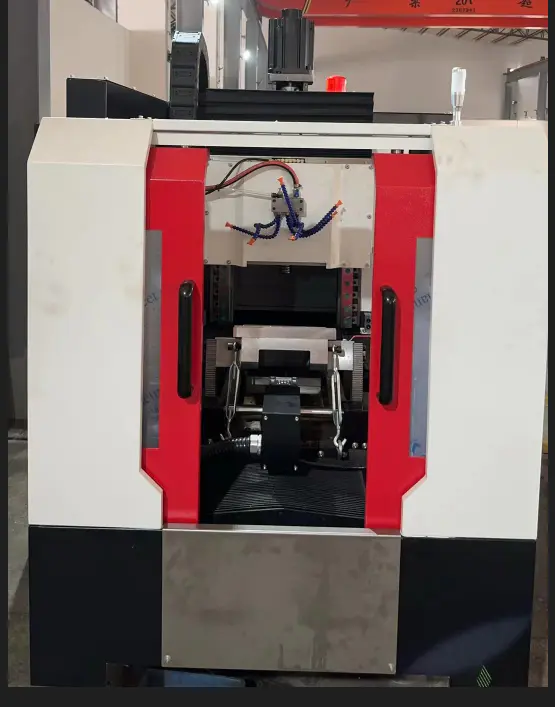

1. Good rigidity, high precision skiving fin, wide application range, easy to operate;

2. Parametric variable program, users only need to enter the tool parameters and related process parameters to achieve

processing, no programming.

3. High efficiency, unique numerical control technology, to ensure that the machine high-speed operation, stable and no

impact.

4. CNC skiving fin heat sink machine and skiving grinding tool holder, so that the skiving process change is simple and

convenient, the cross tool holder has a quick return handle and an adjustable limit rod, can be quickly and accurately

adjusted to the next cutting depth.

5. Intelligent, data input, human-computer interaction interface, through simple data input can achieve automatic control

processing.