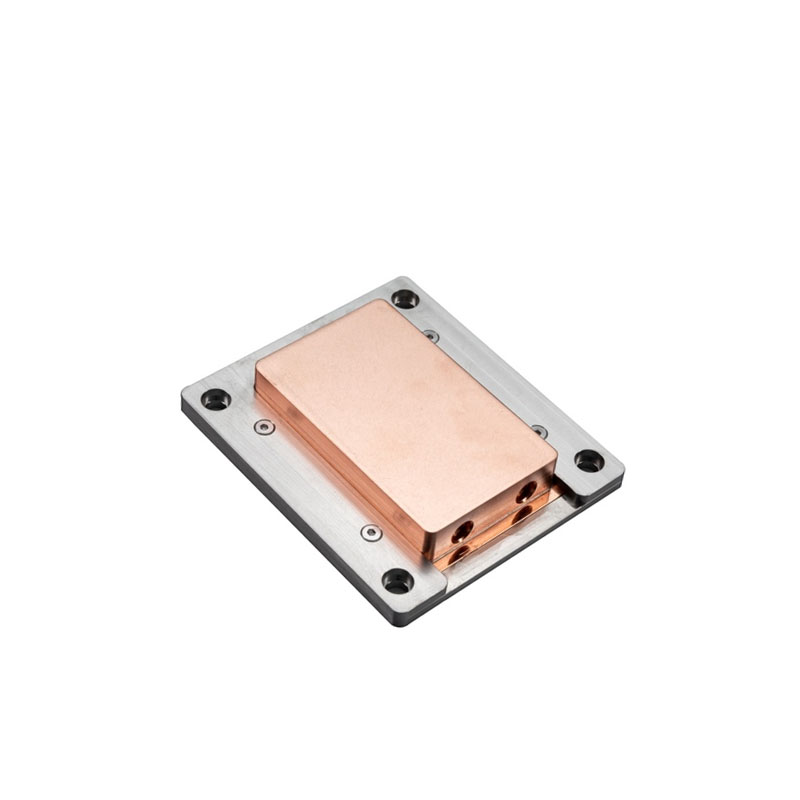

Server Liquid Cooling Loop Direct to Chip Vacuum Brazing Cold Plate

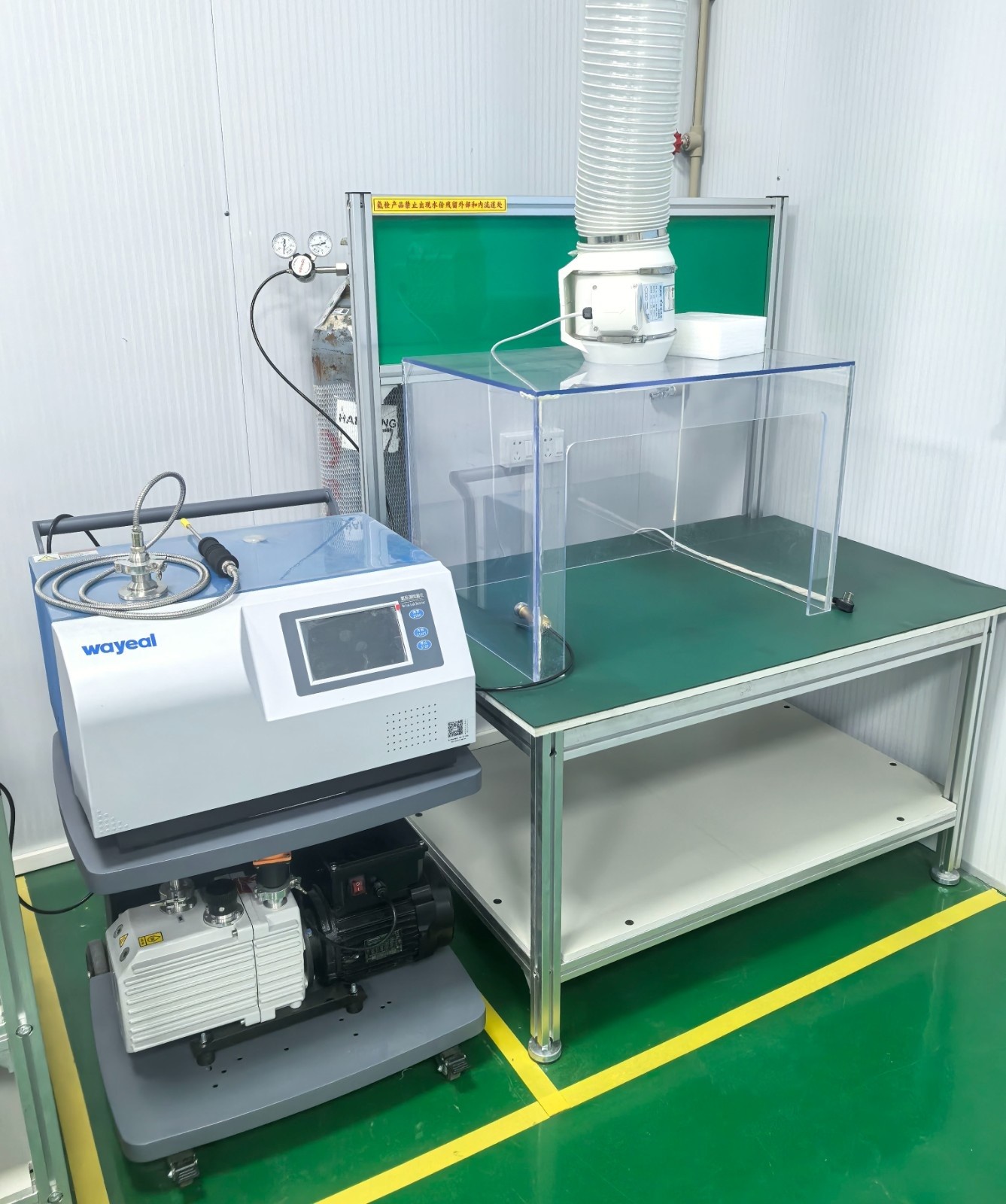

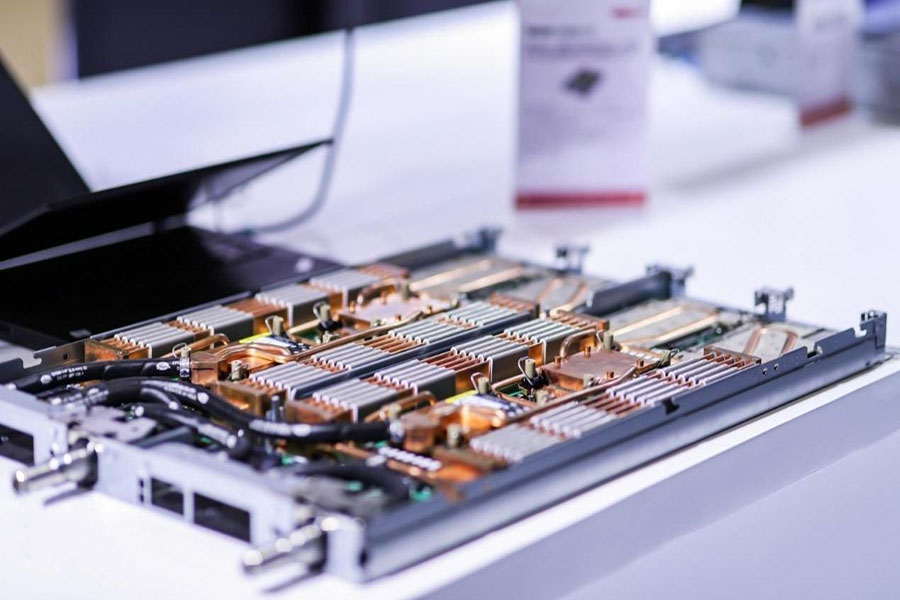

The direct to chip cold plate is made of high-purity C1100 material with excellent thermal conductivity, which can effectively and quickly conduct heat away from high heat density components (e.g. CPU, GPU) inside the server. Lori copper liquid cooling components are soldered using a vacuum brazing process to provide superior cooling loop components for high performance computing devices in server machines. The surface of the cold plate is treated with anti-oxidation and nickel plating, which not only enhances the corrosion resistance of the cold plate, but also effectively extends its service life. During long-term operation, copper oxidation, corrosion and reaction with coolant can be effectively avoided to maintain good heat dissipation performance.