Stainless Steel Water Manifold Block for Server Liquid Cooling

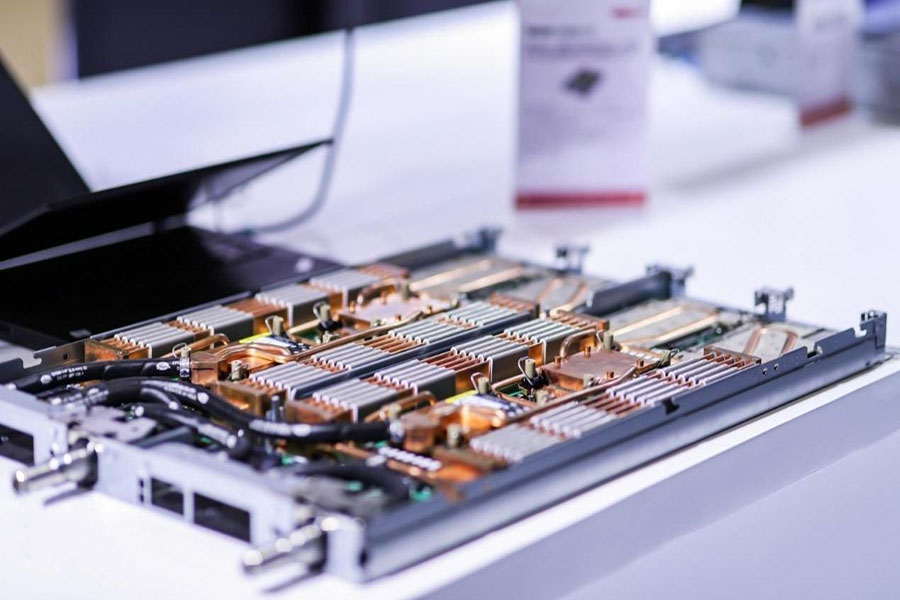

The server manifold block, designed to optimize the efficiency and reliability of data center liquid cooling systems, directs coolant to each component of the system in a single pass, simplifying tube routing. Manufactured from high quality SUS 304 stainless steel, It's rust, temperature and chemical resistant, and can withstand extreme pressures for high-traffic data center liquid-cooling systems. CNC precision machining ensures even distribution of coolant across server racks, eliminating hotspots and improving cooling efficiency. Standard or customizable threaded ports provide airtight sealing and reduce the risk of downtime and maintenance. Lori manifold blocks are flexible and expandable, accommodating a variety of cooling architectures and supporting customized port sizes, making them an ideal solution for high-duty cooling scenarios.