With the rapid development of industrial mechanization and the rapid advancement of power electronics, the application scenarios are continually expanding: electric vehicles, wind turbines, high-speed trains, power grids, aerospace, and more. The usage environment is complex and variable: equipment often faces various external conditions such as high temperatures, high humidity, high salinity, vibration, and even vacuum conditions, subjecting the equipment and its internal components to various tests.

High-power density power electronics are core components in electric vehicles, wind turbines, high-speed trains, power grids, and other applications. Currently, high-power power electronics are developing towards higher power levels and higher integration, so heat dissipation issues inevitably receive attention, placing higher demands on the equipment's cooling system.

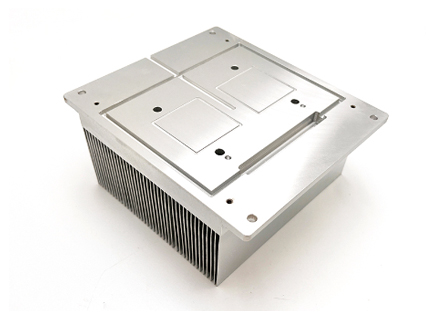

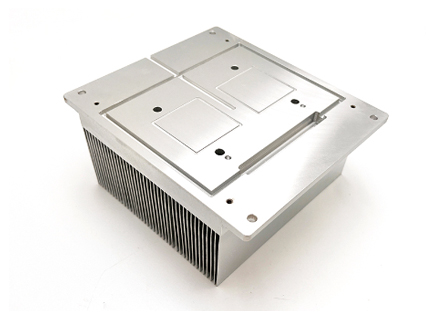

In our daily lives, although not always visible, heat sinks are hidden in various common devices: automotive radiators, communication base station heat sinks, locomotive heat sinks, wind turbine heat sinks, power supply heat sinks, electronic heat sinks, electrical appliance heat sinks, LED light heat sinks, mechanical equipment heat sinks, new energy heat sinks, power semiconductor heat sinks, inverter heat sinks, CNC machine tool heat sinks, etc.

Why are most heat sinks made of aluminum?

Aluminum alloy heat sinks are characterized by their lightweight and excellent thermal conductivity. Aluminum heat sinks not only have a lightweight and compact size, which does not occupy indoor space, but also offer excellent heat dissipation performance, allowing room temperature to rise quickly. However, the price is higher compared to steel heat sinks. The efficient heat dissipation performance of aluminum heat sinks can reduce energy consumption during use and achieve energy-saving and environmental protection effects. As a result, more manufacturers are starting to choose aluminum heat sinks.

Aluminum profiles, made from pure aluminum or aluminum alloy, can be formed into metal panels with various cross-sectional shapes through processes such as melting, cutting, and extrusion. These profiles can then be processed with surface treatments like brushing, sandblasting, electroplating, laser engraving, and anodizing to create finely finished, high-performance, and stable heat sink housings. Aluminum profiles have the following main characteristics:

01 Light Weight

The density of aluminum profiles is only 2.7 g/cm³, about one-third of the density of steel and copper (7.85 g/cm³ and 8.9 g/cm³, respectively), making it a lightweight metal. Therefore, when used to make heat sink panels, aluminum profiles are lighter for the same volume. The lightweight aluminum profiles can be used to manufacture thin and light heat sink housings, which aligns with the current trend towards lightweight products.

02 Corrosion Resistance

The operating environment of a heat sink is complex, so the selected material must have good corrosion resistance. Aluminum can form a dense oxide film on its surface to prevent further internal corrosion. Additionally, aluminum profiles that have undergone surface treatment have even better corrosion resistance. Therefore, aluminum profiles can maintain their aesthetic and thermal performance in practical applications without being affected by metal corrosion over time.

03 Thermal Conductivity

Thermal conductivity is an essential performance characteristic for heat sinks. The thermal conductivity of aluminum is 204 W/(m·K). However, pure aluminum has low hardness and is prone to deformation when heated. By forming pure aluminum into aluminum alloy, both excellent thermal conductivity and long-term durability of the heat sink can be ensured. Although copper has better thermal conductivity than aluminum, it cannot achieve the lightweight and thin profile that aluminum alloys can, and copper is also more expensive. Thus, aluminum profile heat sinks are more popular in the market.

04 Non-Magnetic

Non-magnetism is also an important property for heat sink housings. Heat sinks used in audio equipment and electronic products must be non-magnetic to avoid interference with signal transmission. Aluminum alloys, which do not contain iron, cobalt, nickel, or other magnetic metals, are non-magnetic and do not interfere with the normal operation of audio and electronic products.

05 Plasticity

The specific tensile strength, yield strength, ductility, and corresponding work hardening rate of metals affect the range of deformation. Different metals have varying plasticities, and aluminum alloys are easy to forge and have high plasticity, making them widely used in the industry.

In heat sink manufacturing, Al6063/Al6061 aluminum alloys are used. Due to their superior plasticity, they can be processed into heat sinks of various shapes, including sunflower shape, flat wide shape, round shape, comb shape, fishbone shape, and fin shape. With additional surface treatments such as brushing, sandblasting, and laser engraving, the appearance of the products can be customized according to customer designs, meeting the shape requirements of different industries and products.

Lori has been focused on the heat sink field for nearly ten years and can provide you with one-stop heat dissipation solutions. Feel free to contact us.