In an electric car, a battery discharge generates heat, and the faster it is discharged, the more heat it generates. Batteries work on the principle of voltage difference, and at high temperatures, the electrons inside are excited, which reduces the voltage difference between the two sides of the battery. If there is no cooling system to keep it within the working range, the battery will stop working, and if the internal temperature difference is large, it may cause the charge and discharge rate of each cell to be different, thereby reducing the performance of the battery pack. If the battery overheats or the temperature distribution in the battery pack is not uniform, there may be potential thermal stability issues, such as capacity loss, heat loss and fire and explosion, and in the face of life-threatening safety issues, the electric vehicle industry is constantly innovating to improve battery cooling systems.

A research team compared four different methods of lithium-ion soft-pack battery cooling: air, indirect liquid, direct liquid, and fin cooling systems. The results show that the air cooling system needs 2 to 3 times more energy than other methods to maintain the same average temperature. Minimum temperature climb of indirect liquid cooling system; The fin cooling system increases the battery weight by about 40%. Indirect liquid cooling is a more practical form than direct liquid cooling.

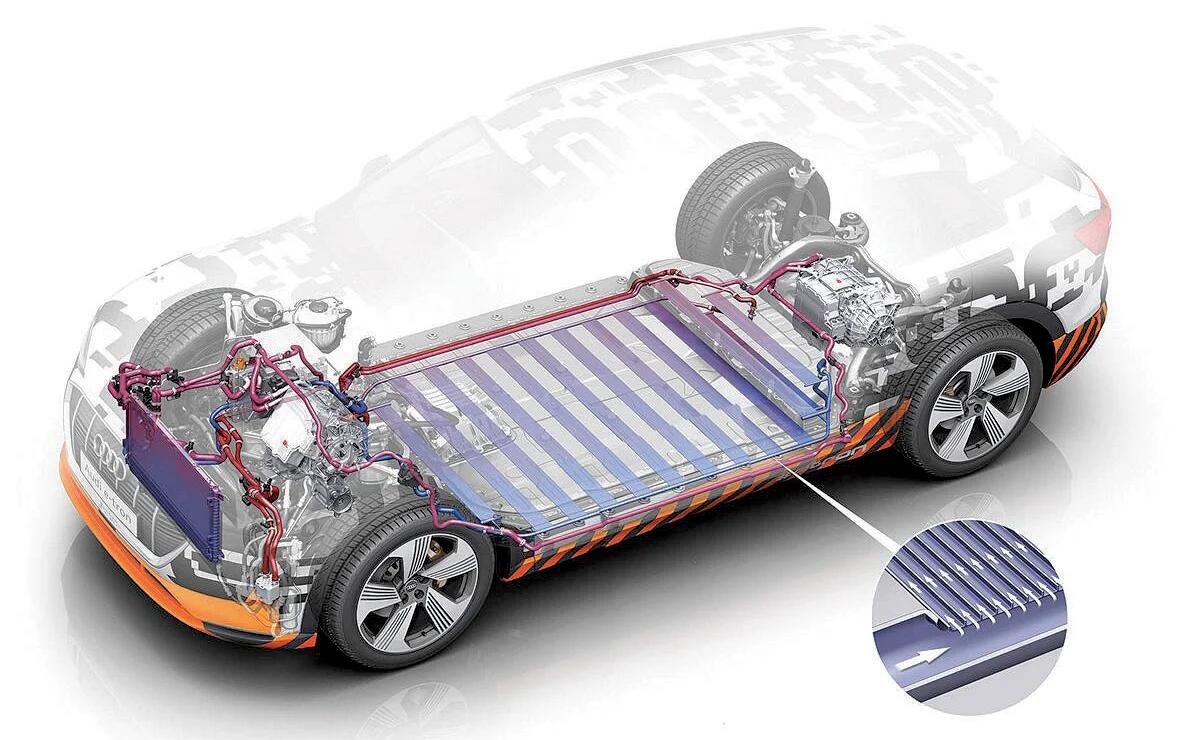

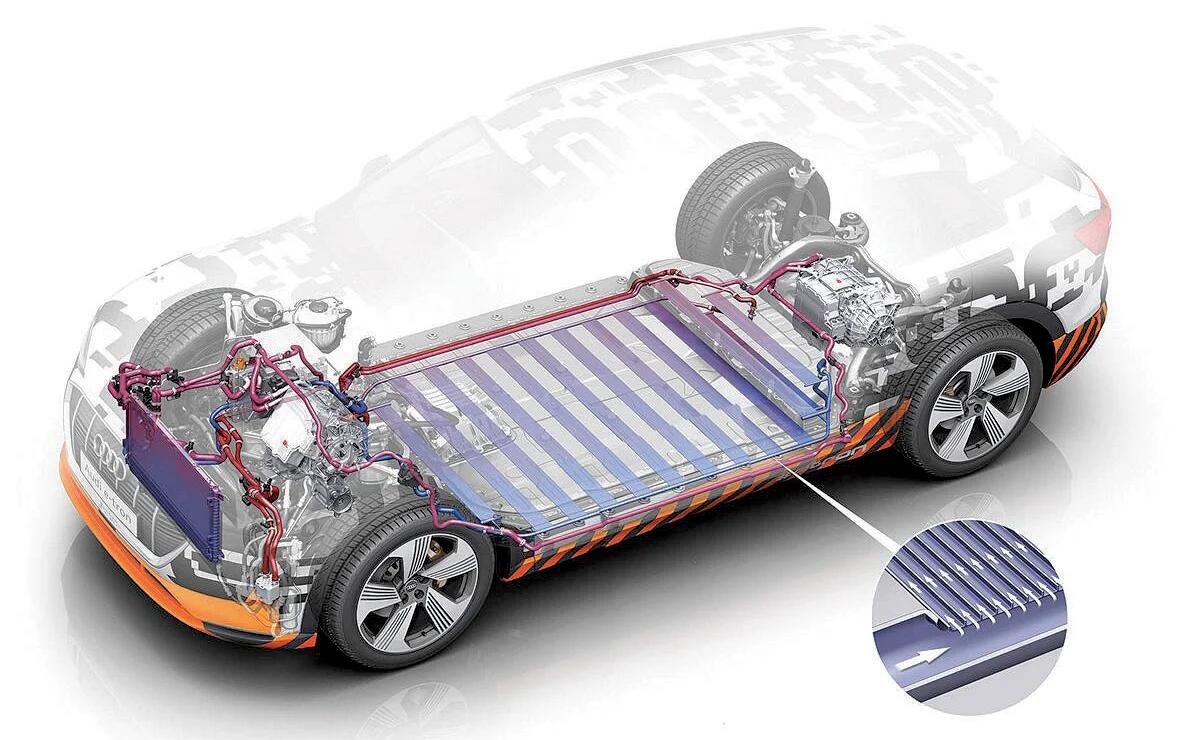

In a liquid cooling system, whether the battery is immersed in the liquid or whether the liquid is pumped through a pipeline divides direct and indirect cooling.

Direct cooling systems, which put the battery pack in direct contact with the coolant, are not currently used in cars on the market, and this solution is in the development stage, because of the need for new coolants, direct cooling is more difficult to achieve. And the battery is in contact with the liquid, the coolant needs to have low or no conductivity.

Indirect cooling systems are similar to ICE cooling systems in that both circulate liquid coolant through a series of metal tubes. However, the structure of the cooling system will look very different in an electric vehicle, achieving uniformity of the cooling temperature and the structure of the cooling system will vary depending on the shape of the battery pack.

Due to the widespread use of electric vehicles, there are also higher requirements on battery life and power output, and in order to achieve this, battery thermal management systems need to be able to transfer heat away from the battery pack at higher rates of charging and discharging. While some companies are already using indirectly cooled battery packs, ongoing research and development on battery packs and coolants is needed to improve the safety of electric vehicles.