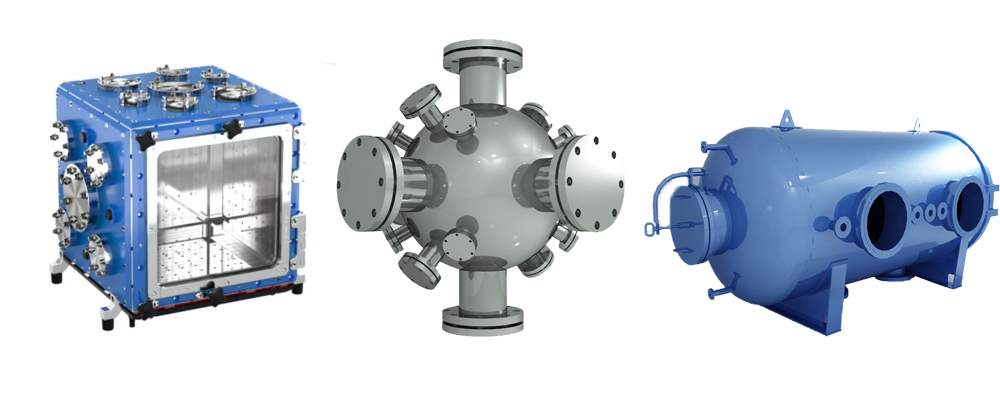

What Are Vacuum Chambers and Modular Vacuum Chambers?

A vacuum chamber is the core part of a vacuum system. Vacuum chambers provide an enclosed space for creating and maintaining vacuum conditions in industrial production, experimental research and other fields. Modular vacuum chambers has flexibility in that the basic vacuum chamber components can be used to freely assemble the chamber according to the user's needs. Vacuum chambers are available in various shapes such as rectangular, cylindrical and spherical and so on. The shape of a vacuum chamber is determined by its application. Vacuum chambers provide vacuum testing and product manufacturing conditions for industries such as manufacturing, aerospace, food industry, biopharmaceutical industry and others.

Why Vacuum Chambers Need Cooling Solutions?

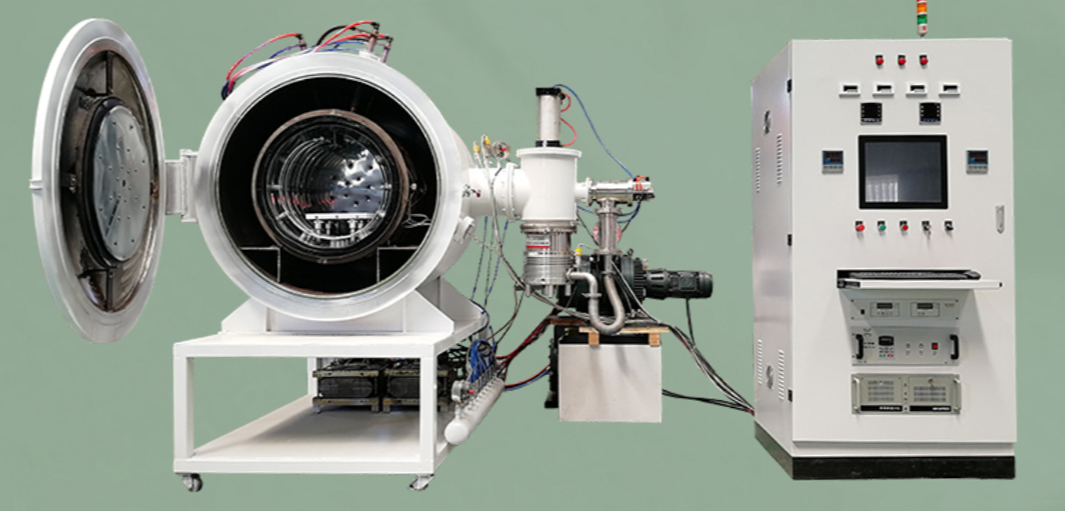

Vacuum chambers are generally maintained a vacuum environment by O-rings or metal seals. High temperatures can lead to aging and failure of the seals, which can affect the vacuum level of the chamber. If the chamber is to make temper and other processes (e.g. heat treatment in vacuum furnaces, vacuum coating, plasma processes, etc.), a large amount of heat will be generated internally, and high temperatures will cause the structural materials of the chamber to expand and deform and be damaged by elevation, thus affecting the vacuum tightness. Cooling solutions can provide you with air and water cooling systems to cool down the walls and seals of the vacuum chamber and ensure the vacuum tightness of the chamber.

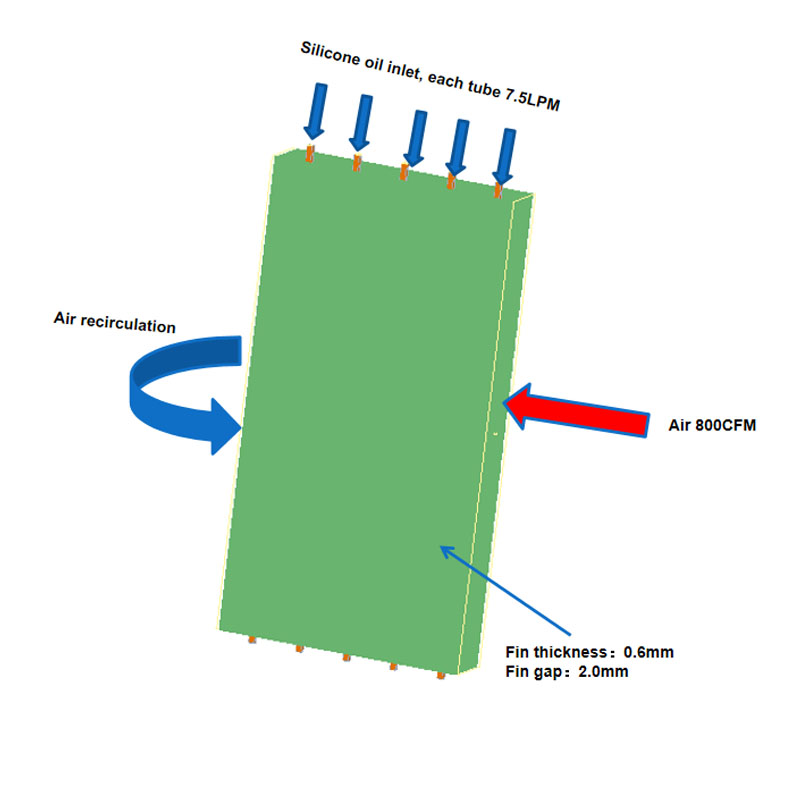

An equipment manufacturer is seeking to customize a heat exchanger for his modular vacuum chamber with a power rating of 10,000W. Given the high power consumption, we are considering an integrated cooling solution combining air and liquid cooling. Aluminum fins combined with stainless steel tubes are used for the heat exchanger, and the fin process will employ zipper fin technology.

Specification: Liquid: Silicone oil

Liquid: Silicone oil

Total flow rate: 37.5 LPM, with 7.5 LPM per ½" tube

Inlet and outlet pressure difference per ½" tube: Approximately 0.7psi to 1psiSimulated temperature: -40°C

Total heat source: 10,000W

Maximum temperature not to exceed 90°C

Airflow rate: 800 CFM

The heat exchanger is installed in a sealed and insulated chamber with

dimensions 4ft x 4ft x 4ft. Air is recirculated within the chamber.

Simulation Module:

Silicone Oil Properties:

1. Volumetric Expansion Coefficient: 9.0 × 10⁻⁴ /°C

2. Viscosity: 100 cSt

3. Density: 0.96 g/cm³

4. Specific Heat Capacity: 1460 J/kg·°C

5. Thermal Conductivity: 0.15 W/m·K

6. Thermal Diffusivity: 1.0 × 10⁻⁷ m²/s

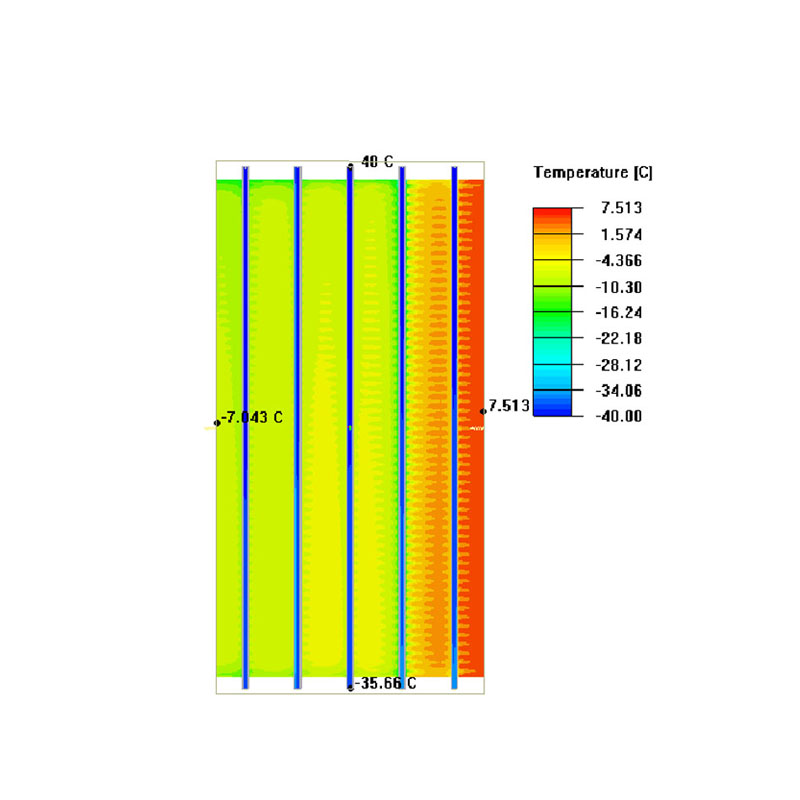

Simulation Results:

At 6000W heat load

Air Side:

Inlet air temperature: 7.513°C

Outlet air temperature: -7.043°C

Liquid Side:

Inlet liquid temperature: -40°C

Outlet liquid temperature: Approximately -35.66°C

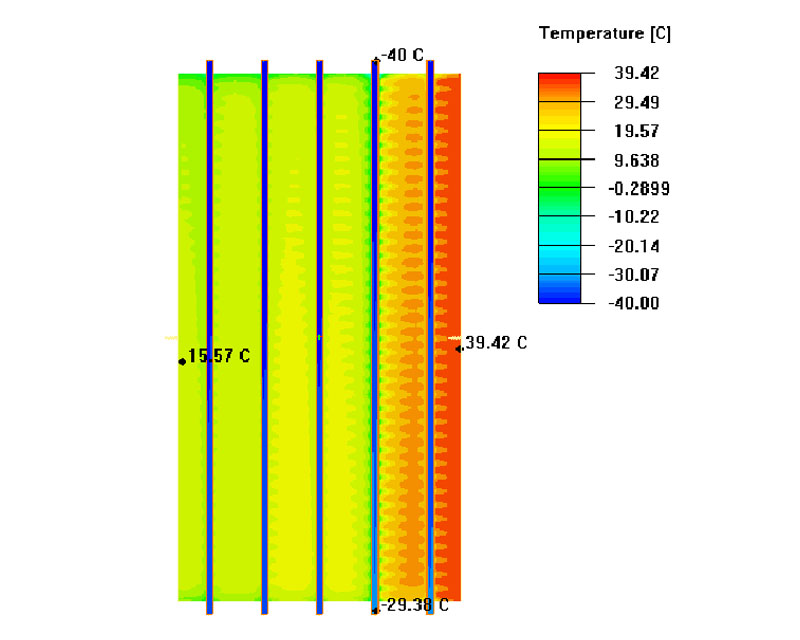

At 10,000W heat load:

Air Side:

Inlet air temperature: 39.42°C

Outlet air temperature: 15.57°C

Liquid Side:

Inlet liquid temperature: -40°C

Outlet liquid temperature: Approximately -29.38°C

Summary:

CASE | Airflow (CFM)

| Silicone Oil Flow (LPM) | Inlet Air Temp (°C) | Outlet Air Temp (°C) | Inlet Liquid Temp (°C)

| Outlet Liquid Temp (°C) |

6000W | 800

| 7.5/ per tube | 7.513

| -7.043

| -40

| -35.66 |

| 10000W | 800 | 7.5/ per tube | 39.42

| 15.57

| -40 | -29.38 |

Lori's innovative custom modular vacuum chamber air-cooled and liquid-cooled integrated cooling solutions are suitable for vacuum chambers that need to operate in high temperature and high load environments, providing more reliable and stable equipment for semiconductor fabrication, laser processing and other high-tech applications. For more innovative customized efficient cooling solutions, please contact us in time.