With the explosive growth of artificial intelligence, cloud computing and big data, data centers for AI models on major platforms such as ChatGPT, DeepSeek and others are moving toward high density and high energy consumption, and liquid-cooling technology has become the mainstream choice thanks to its highly efficient heat dissipation capability. However, one of the core challenges of liquid-cooling systems - coolant leakage - can trigger serious consequences such as equipment damage, fire and even data loss.

Why is leakage prevention in liquid cooling systems so critical?

Safety Risks: Coolant is a conductive liquid, so a leak could short-loop loops, cause a fire, or paralyze equipment. If a small leak in a data center is not detected in time, it can eventually lead to the destruction of the entire server rack, resulting in a loss of more than $10 million.

Operating Costs: Leaks not only increase maintenance costs, but also affect service continuity due to downtime. According to statistics, every minute of downtime in a data center costs an average of about $9,000.

Environmental Pressures: Some coolants contain chemicals that can contaminate the environment if spilled. Strict industry standards require companies to monitor leaks in real time and respond quickly.

Every Detail of the Liquid-cooling Component Matters:

Liquid cooling plate

Directly contacting the CPU/GPU, the internal flow path is complex, and weld seams or material defects can easily lead to micro-leakage.

Quick connectors

The core component of the connecting piping, frequent plugging and unplugging or vibration may cause seal failure.

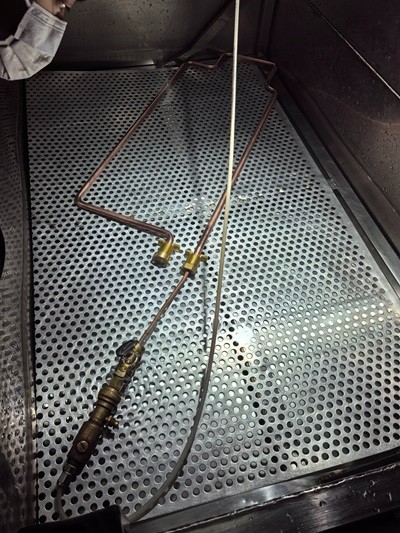

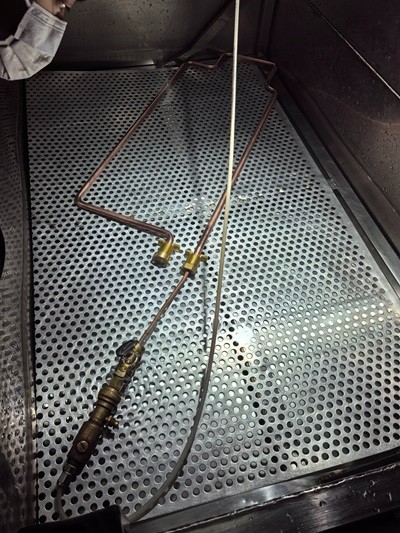

Manifold

Responsible for diverting coolant, the multi-connector structure requires a very high level of sealing process.

Integrated pumps, valves, liquid cooling plates, copper piping, etc. dynamic pressure changes test the stability of the system.

Anti-leakage technology of LORI liquid-cooling components: the whole chain from design to production

In the development and production of liquid cooling system, LORI ensures the sealing and reliability of the components through the following technical solutions:

1. Precision manufacturing and structural innovation

The liquid cooling plate adopts micro-channel vacuum brazing technology. By optimizing the cold plate channel structure (such as designing reasonable channel and fin scheme), it reduces the flow resistance and maintains the heat dissipation efficiency at the same time, and reduces the risk of leakage due to high pressure. Liquid cooling plate, quick connectors and manifolds are welded by vacuum brazing technology, which ensures that the flow channel welds are free of bubbles and cracks, and the leakage rate is lower than 0.001mL/min.

2. Modular and insurance reliable seal design

The manifold and Lori's customized liquid-cooling loop components reduce the number of weld points through modular design, thus keeping the number of leakage points down. The quick connectors and manifold manifold joints are double sealed with O-rings + metal gaskets to withstand extreme temperatures. The quick connectors automatically close the channel at the moment of insertion and removal, preventing coolant from dripping.

Leakage detection method of LORI liquid-cooled components: accurate, efficient and full process coverage

1. Liquid-cooled panels: “full body checkup” for micro-leaks

Helium mass spectrometry: Helium is injected into the vacuum chamber, with a detection sensitivity of 10-⁹ Pa-m³/s, which can locate sub-micron defects.

Infrared Thermal Imaging: Simulates heat dissipation conditions and identifies flow path blockages or potential leak points through temperature distribution anomalies.

2. Quick connectors: simulated testing under extreme conditions

Insertion and withdrawal cycle test: Repeated insertion and withdrawal at 85℃ high temperature and -25℃ low temperature to verify the durability of seals.

Burst pressure test: Apply 2 times the rated pressure (up to 6MPa) to ensure that there is no deformation or leakage.

3. Manifold and liquid loop components: system level verification

Multi-phase flow test platform: Simulate the coolant gas-liquid mixing flow condition and monitor the pressure and flow consistency of each interface.

The safety of liquid cooling system is not an abstract concept, but a line of defense constructed by each component, each process, and each inspection, LORI through the whole chain of technological innovation of design - manufacturing - inspection - operation and maintenance, so that the liquid cooling plate, quick connectors, manifolds and other components in the high efficiency of heat dissipation at the same time, to achieve the promise of “zero leakage”. In the future, we will continue to work on the details of component-level technology to provide data centers with a smarter and more reliable liquid cooling infrastructure.