With increasing environmental awareness and reduced dependence on traditional energy sources, new energy vehicles are gradually becoming a hot topic in the global automotive industry. As a critical component of new energy vehicles, water cooling plate materials play an important role in their research, development, and application. This article explores in detail the development and application of water cooling plate materials in new energy vehicles, highlighting their significance and development trends in the industry.

Water cooling plate materials are essential elements for managing the thermal conditions of vehicle batteries through water-based cooling methods. In new energy vehicles, batteries serve as crucial power storage units, and prolonged high-energy consumption can lead to increased battery temperatures, affecting performance and lifespan. To address this issue, water cooling systems are widely employed in new energy vehicle battery systems, with water cooling plate materials playing a pivotal role in these systems.

Advantages of Water Cooling Plate Materials in Development and Application:

Water cooling plate materials exhibit excellent thermal conductivity and high temperature resistance, effectively absorbing and dissipating heat from within the battery. This ensures the battery operates at lower temperatures, thereby enhancing its performance and lifespan.

Additionally, water cooling plate materials can reduce the weight and volume of battery systems, improving overall vehicle energy efficiency, reducing energy consumption, and increasing the driving range of new energy vehicles.

Therefore, the development and application of water cooling plate materials are of significant importance to the advancement of the new energy vehicle industry.

Breakthroughs in the Development of Water Cooling Plate Materials:

In recent years, with the rapid growth of the new energy vehicle market, there have been significant breakthroughs in the development of water cooling plate materials.

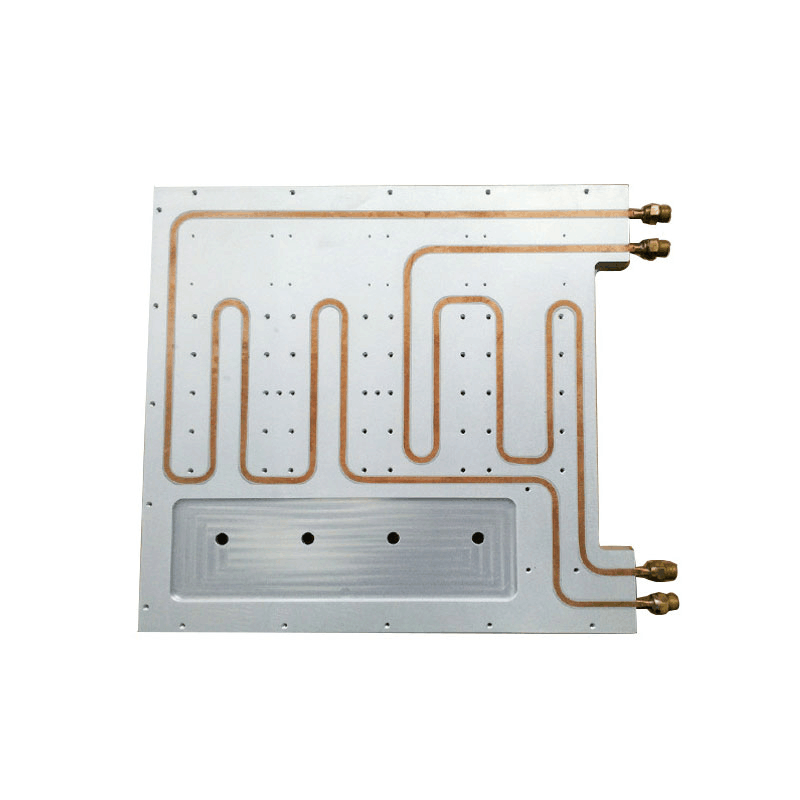

Firstly, traditional copper-based materials are gradually being replaced by new materials such as aluminum-based materials and carbon fiber composites. These new materials offer higher thermal conductivity and lighter weight, better meeting the demands for lightweight and efficiency in new energy vehicles.

Secondly, there have been continuous improvements in the structural design of water cooling plate materials. Innovative plate structure designs increase surface area, thereby enhancing heat dissipation efficiency.

Moreover, the use of microchannel designs further improves the thermal conductivity and heat dissipation effectiveness of water cooling plate materials. These structural innovations have widened the application scope of water cooling plate materials in new energy vehicles.

The development and application of water cooling plate materials are also influenced by manufacturing processes. Currently, major manufacturing processes include pressure welding, adhesive bonding, and laser welding, among others. These processes are continually optimized and improved to enhance the manufacturing efficiency and quality of water cooling plate materials. Additionally, the emergence of new materials and manufacturing technologies is gradually reducing production costs, thereby promoting the market application of water cooling plate materials.

Challenges and Opportunities in the Development and Application of Water Cooling Plate Materials for New Energy Vehicles:

Firstly, optimizing design and improving manufacturing precision are critical challenges. Designing more efficient and lightweight water cooling plate materials that can be mass-produced is crucial for further application.

Secondly, the rapid growth of the new energy vehicle market presents significant development opportunities for water cooling plate materials. As sales of new energy vehicles continue to increase, the demand for water cooling plate materials is expected to grow substantially.

Therefore, manufacturers of water cooling plate materials should actively invest in technological research and expand production capacity to meet market demands.

In summary, the development and application of water cooling plate materials are crucial for the advancement of the new energy vehicle industry. These materials possess excellent thermal conductivity and high temperature resistance, ensuring batteries operate at lower temperatures to enhance their performance and lifespan. With the rapid growth of the new energy vehicle market, continuous breakthroughs in the development and application of water cooling plate materials are anticipated. Challenges and opportunities exist in optimizing design, improving manufacturing processes, and meeting the increasing market demand for water cooling plate materials in new energy vehicles. Looking ahead, the future prospects for the development and application of water cooling plate materials are promising, making significant contributions to the sustainable development of the new energy vehicle industry.