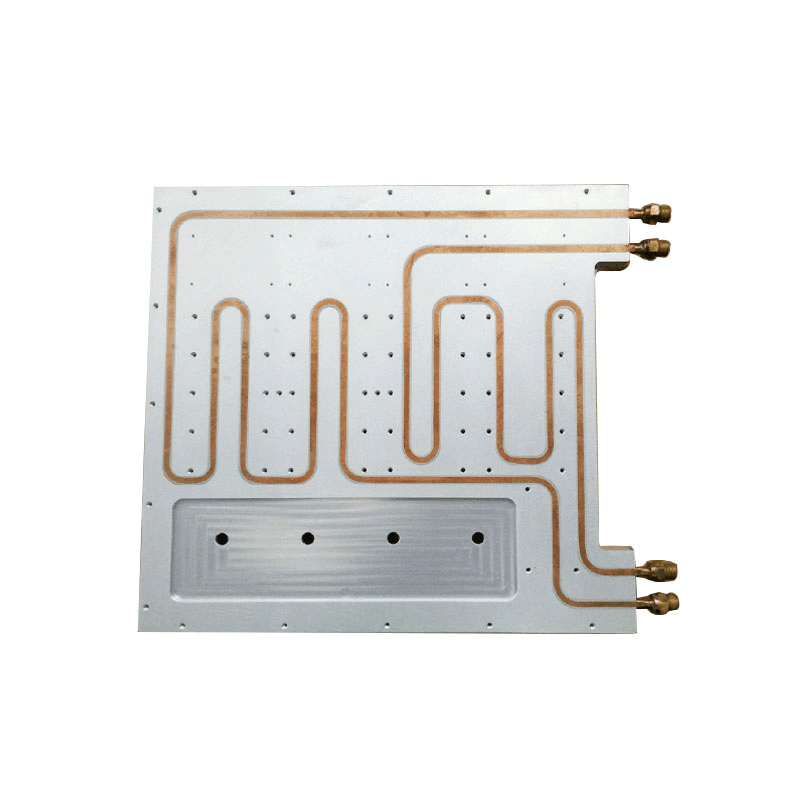

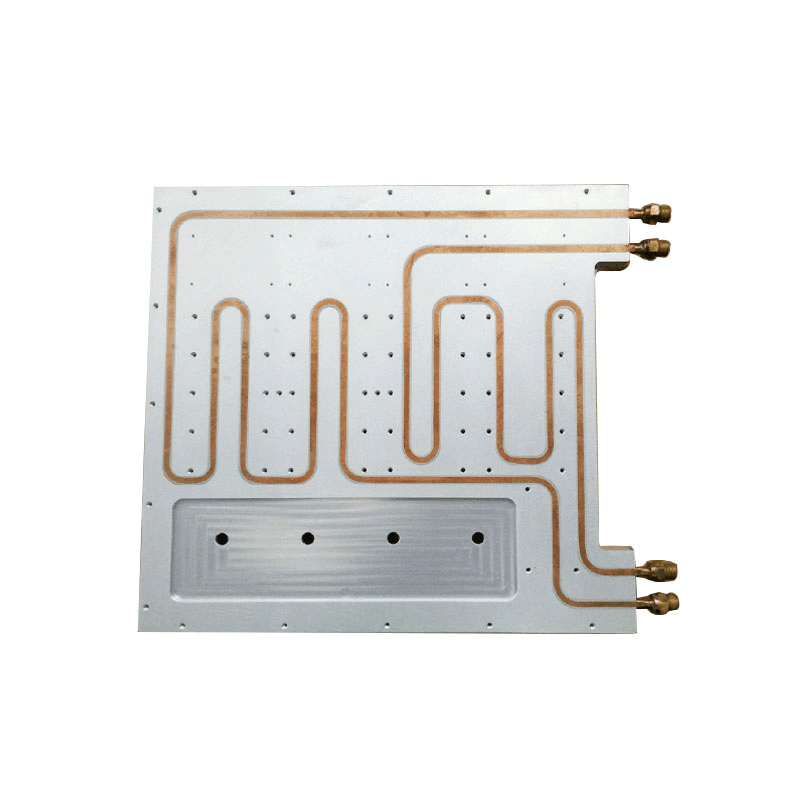

The aluminum alloy vacuum brazed high power IGBT liquid cooling plate is a specialized solution designed for high-power IGBT (Insulated Gate Bipolar Transistor) heat dissipation, widely applied in power electronic devices such as electric vehicles, power converters, and industrial control systems. Below is a detailed description of the technical specifications, manufacturing process, and application advantages of this liquid cooling plate:

Technical Data

1. Heat Dissipation Capability:

- Rated Power: 2500W and above

- Thermal Resistance: <0.02°C/W

- Temperature Drop: Maintains operating temperature below 70°C under high power conditions (depending on specific cooling system design).

2. Materials:

- Plate Material: High thermal conductivity aluminum alloy (such as 6061 or 1050)

- Cooling Liquid: Typically water or water-glycol mixture; special cooling liquids can also be used for enhanced performance.

3. Physical Dimensions:

- Size: Customizable based on equipment design, typically around 300mm x 400mm

- Thickness: 10mm to 20mm

4. Flow Rate:

- Cooling Liquid Flow Rate: 4-8 L/min

- Inlet/Outlet Pressure Difference: 0.1-0.5 bar

Manufacturing Process

1. Design and Simulation:

- Design and simulate using Computational Fluid Dynamics (CFD) software to optimize cooling liquid flow channel structure for uniform heat dissipation.

- Thermal simulation ensures reliability and performance of the liquid cooling plate under high power conditions.

2. Material Selection:

- Use high thermal conductivity aluminum alloys (such as 6061 or 1050) known for efficient heat dissipation and mechanical strength.

3. Channel Processing:

- CNC Machining: Precision CNC machining of flow channels on aluminum alloy plates to ensure accuracy and consistency.

- Etching: Chemical etching technology used to create complex flow channel structures suitable for high precision and intricate designs.

4. Brazing Encapsulation:

- Vacuum Brazing Process: Utilize vacuum brazing to join flow plates and cover plates together. Vacuum brazing provides an oxygen-free environment to prevent material oxidation, ensuring welding quality.

- Brazing Material: Aluminum-based brazing alloys (such as Al-Si alloy brazing materials) ensure welding strength and thermal conductivity.

5. Surface Treatment:

- Anodizing: Anodize the surface of aluminum alloy to enhance corrosion resistance, surface hardness, and prolong service life.

Application Advantages

1. Efficient Heat Dissipation:

- Liquid cooling plates with capacities of 2500W and above efficiently dissipate heat, keeping high-power IGBTs cool under heavy loads for stable operation.

- Compared to traditional air cooling, liquid cooling plates offer lower thermal resistance, facilitating faster heat conduction and dissipation.

2. Energy Saving:

- Enhanced heat dissipation efficiency of liquid cooling plates allows devices to operate more efficiently under the same power consumption, reducing energy wastage.

- Reduces power consumption due to overheating, further enhancing energy utilization efficiency.

3. Increased Equipment Density:

- Liquid cooling technology enables efficient heat dissipation in a smaller space, allowing for compact equipment designs and increased equipment density.

- Particularly beneficial for high-power electronic devices, optimizing space utilization.

4. Reduced Noise:

- Liquid cooling systems operate with lower noise levels compared to air cooling systems, reducing fan noise and improving quiet working environments.

- Especially suitable for office areas and laboratories requiring quiet environments.

5. Enhanced System Reliability:

- By effectively controlling temperatures, liquid cooling plates reduce equipment failures and performance degradation due to overheating, extending equipment lifespan.

- Improves operational reliability under extreme conditions, ensuring stable execution of critical tasks.

Real-World Applications

1. Electric Vehicles:

- High-power IGBT modules (such as inverters and DC-DC converters) in electric vehicles use liquid cooling plates for efficient heat dissipation, ensuring system reliability and performance.

- Enhances overall energy efficiency of electric vehicles and extends driving range.

2. Power Electronic Devices:

- IGBT modules in power converters and inverters utilize liquid cooling plates to improve heat dissipation efficiency, ensuring stable operation under high-power output.

- Reduces equipment volume and weight, enhancing installation flexibility.

3. Industrial Control Equipment:

- High-power IGBT modules in industrial control systems employ liquid cooling plates to enhance heat dissipation efficiency, ensuring stable operation under high load conditions.

- Improves equipment reliability and lifespan."

This translation provides a comprehensive overview of the aluminum alloy vacuum brazed high power IGBT liquid cooling plate, detailing its specifications, manufacturing methods, advantages, and practical applications in English.