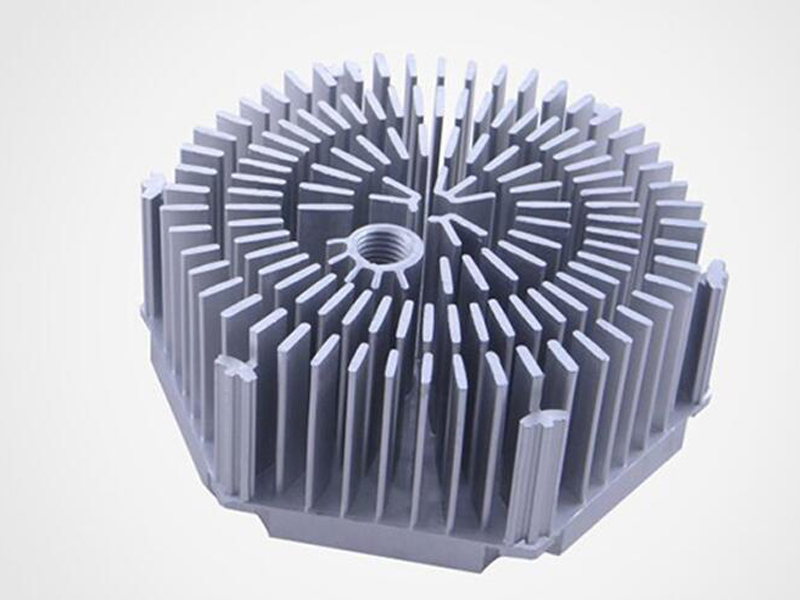

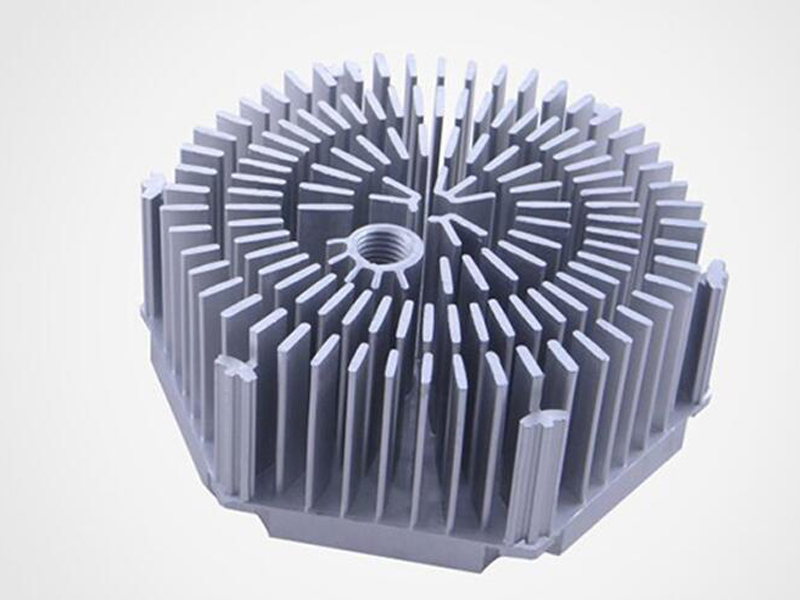

1.the function and material selection of the heat sink

The heat sink is a device used to dissipate heat, and the waste heat of the machine is dispersed through it to ensure the stability of the operation of the machine. The main materials of the heat sink are aluminum alloy and copper alloy, because these materials have good thermal conductivity, high strength and strong corrosion resistance, and can meet the working requirements of the heat sink.

2. Implementation of cold forging process

①Raw material preparation: After the selection and ratio of materials, the raw materials such as aluminum alloy and copper alloy are sent to the furnace to melt, and then the rough billet is prepared by the casting process.

②Fine forging: The production of rough forging to improve the performance and density of the material, this process is generally used cold forging process to achieve. Cold forging process is a forging process carried out at room temperature, through processing to adjust the structure of the material, so as to improve the strength, toughness and durability of the material.

③Cutting and trimming: After the forging is completed, the forgings need to be cut and trimmed to achieve the required size and shape.

3. the application of heat treatment process

After the completion of cold forging, the hardness and strength of the forging will increase, but the toughness and plasticity will decrease. Therefore, heat treatment is required to change the properties of the material by heating and cooling at high temperatures to achieve the required mechanical and physical properties. Commonly used heat treatment processes include aging treatment, annealing treatment, quenching treatment and so on.

4. the assembly and application of the heat sink

After the heat treatment is completed, the assembly and assembly of the heat sink can be carried out, and the welding and connection work can be carried out according to the requirements, and the manufacturing of the heat sink can be finally completed. The produced heat sink can be applied to various mechanical equipment, electronic equipment and other fields to stabilize the operation of equipment.