After a series of tests of silicone grease and liquid metal heat conduction agents, the results obtained led the author to look at the situation that the temperature difference of most high-end silicone grease in the market was no more than 5 degrees Celsius at the processor core frequency (120W power consumption).And liquid gold can open the gap of about 10 degrees Celsius directly under the same configuration, but liquid gold is not something new, and has been active in high-end fields before, only in recent years in the public line of sight.

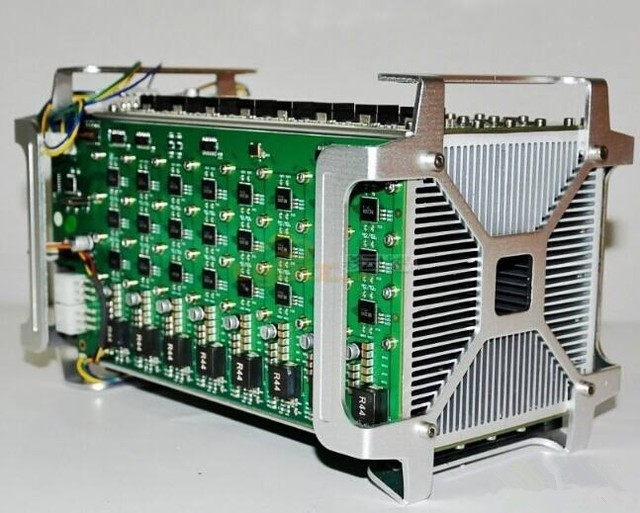

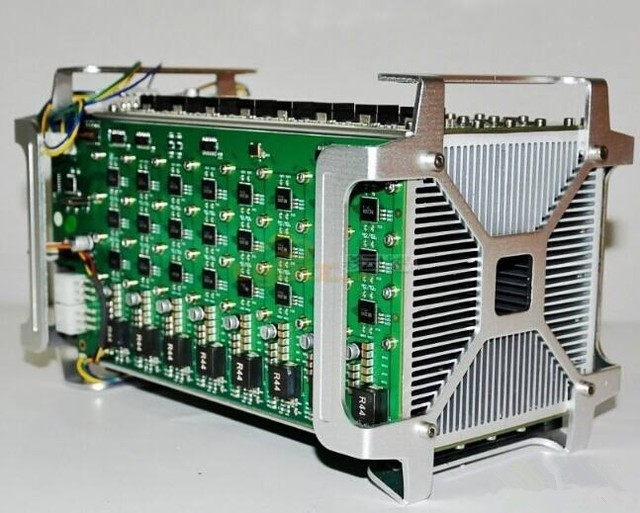

Liquid metal heat conductors used to interface with high energy densities before civilian use, such as shipborne laser cannons, laser cutters, or as heat transfer liquids in nuclear power plants.In recent years, some of the bitcoin mining machines produced are also using liquid metal heat conductors on the interface.

Liquid metal heat conduction agent is generally divided into two kinds, gallium base alloy and bismuth base alloy, gallium base alloy production of liquid metal heat conduction agent is generally a room temperature liquid, such as the lid regular cool cool bo.Bismuth base alloys are usually solid at room temperature and are used as liquid metal heat conductors in thermal conductivity products.

Conventional silicone grease has reached its limits

Everybody knows, coefficient of conduction of heat is an important index that serves as conduction of heat agent, affect conduction of heat directly effect, although radiator is powerful to cannot imagine, but the conduction of heat agent that does not have a performance is tough also is twice the effort with half the effort.The most common heat conduction agent in DIY is silicone grease. At present, the technology is very mature and has been widely used in the field of heat dissipation.

However, no matter how strong the silicone grease is, at present, the highest thermal conductivity is only the super-cool diamond nano-diamond thermal conductivity silicone grease and LT COOLING black pipe silicone grease, with the thermal conductivity reaching 11w·mk, which is the highest known thermal conductivity silicon grease in the retail market (the actual measurement of violent bear has proved that the thermal conductivity is a virtual standard).

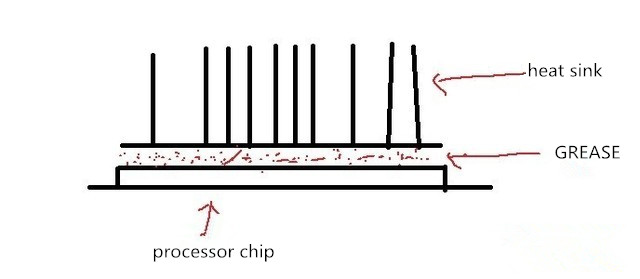

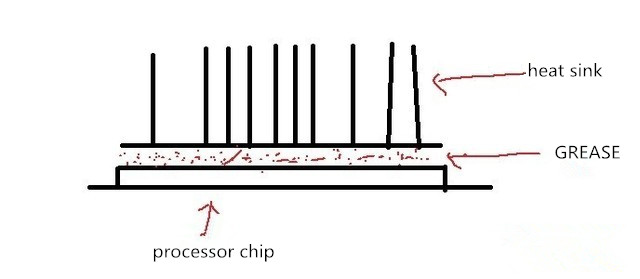

We all know that the thermal conductivity principle of silicone grease is to fill the gap between the interfaces, so that the thermal conductivity area is larger, and the silicone oil inside the silicone grease plays the role of binding filler, the filler is the main thermal conductivity medium, the size of particles directly affects the filling effect between the interfaces, at present, the finer filler is only nano level

Silicone grease filling effect

In order to be safe, the conductivity of silicone grease must be very weak, so at present, some silver and aluminum will be added appropriately on the basis of alumina filler to improve the thermal conductivity, but its role is also very limited, because the smallest particles still cannot reach the level of fully filling gaps.

Advantages of liquid metals

Even if traditional silicone grease does not care about electrical conductivity, it is useless to use metal powder completely. After all, the size of the smallest particles in front of us, the cost of upgrading from micron to nano will increase exponentially, but the performance will not be very strong.

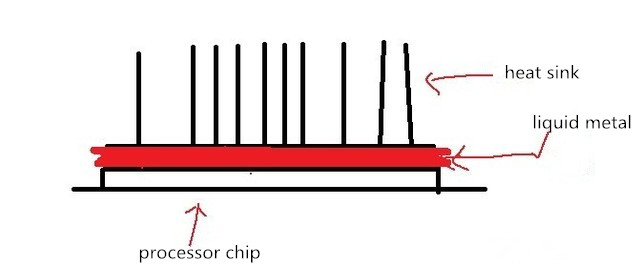

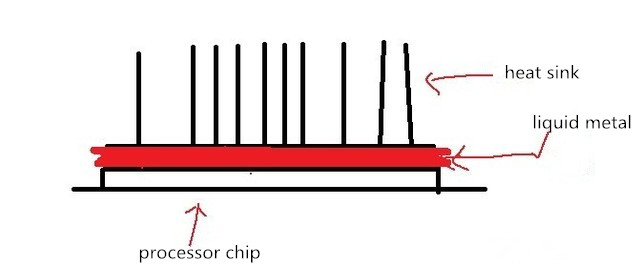

As anyone who has ever studied superior physics knows, metals are made up of atoms directly connected by metal bonds. Gallium atoms have only three electrons in the outer layer, so the binding force between them is very weak. Therefore, gallium-based alloys can only be liquid at room temperature.

Liquid gold filling effect

As a result, gallium atoms can achieve amazing filling effects with almost perfect permeability, and no other metal particles produced by grinding or electrolysis can compare with this natural advantage.Even if the thermal conductivity of high-purity gallium metal is about 30W·mk, it will still be much better than the silver filler products with thermal conductivity up to 400+.

Disadvantages and application range of liquid gold

It is precisely because of this high permeability gallium base alloy can not contact with aluminum products will produce the phenomenon of mutual dissolution, forming a eutectic mixture, so that aluminum base alloy and gallium base alloy produced by the new alloy melting point decreased, aluminum brittle phenomenon.Therefore, its application on many devices is limited.

In the DIY field, aluminum heat sink will not be able to use it as a thermal conductivity, in addition, gallium base alloy will not react with other metals.Another common material in radiator is copper, and copper bottom radiator can be bought easily, unless be low-end radiator still can use aluminium alloy base to fix heat pipe.

The direct contact of the heat pipe will normally touch the aluminum

Pure copper bottom heat sink can be used

There is no problem with nickel-copper

Gallium base alloys and bismuth base alloys do not corrode silicon chips and ni-cu coated CPU tops. The so-called network transmission corrosion is only because gallium base alloys penetrate deep into the CPU or silicon chip surface, which is difficult to clean up, so it can be mistaken for corrosion.In the process of testing, the author also found some ways to make liquid gold easier to clean up.That is, spray alcohol or other cleaners on the surface of liquid gold and gently wipe it with a soft tissue. The paper towel that has been stained with liquid gold should be thrown away. The wiping action should be in one direction and cannot be repeatedly wiped.The liquid gold will go deeper into the interface gaps under pressure, so don't try to rub it out.

At present, liquid metal heat conduction agent is widely used in CPU lid opening, aiming at enhancing the performance of heat conduction medium between silicon chip and top cover.In fact, careful operation of the case can also be used in the top cover and graphics card.In equipment with limited size, such as pen and graphics card docking stations, liquid gold can be used to replace silicon grease to increase thermal conductivity.And the pursuit of stability and heat dissipation of the server after the use of liquid metal, can reduce the temperature at the same time but also reduce the heat dissipation fan revolution, can achieve the effect of cooling and energy saving.

Liquid metal heat conductors are the future trend

In the future, as the research on the use of liquid metal becomes more mature, many consumer or enterprise level devices that need to dissipate heat will increasingly choose liquid metal as the heat conduction agent, and the subsequent change is that the device size will be reduced, or the performance will become stronger under the original size will become possible.