Insulated gate bipolar transistors (IGBTs) are a key component in modern electronics.It is essential in power electronics.IGBTs are known for their high efficiency at high voltages and currents.From automotive inverters in electric vehicles to industrial drives and renewable energy converters, it is critical in a variety of applications.Its good power switching capability makes it indispensable.It improves the performance and sustainability of electronic systems.

However, there is also a major challenge to the operational efficiency of IGBTs: heat generation.IGBTs have high power.They generate a lot of heat.If left unmanaged, this heat can cause thermal stress, reduce efficiency, and shorten device lifetime.High heat can damage semiconductors.It can cause semiconductors to fail under extreme conditions.Therefore, a good cooling solution is crucial.They maintain the safe temperature of the IGBT.This maintains the reliability and durability of the IGBTs.At Lori, we specialize in designing efficient, stable and compact cooling solutions,Liquid Cooling Exchange Solutions.These solutions address the thermal challenges in a wide range of IGBT projects.They improve the performance of many applications.

Understanding IGBT Heating

IGBTs generate heat during operation.This is a natural byproduct of two main mechanisms: conduction losses and switching losses.During the conduction phase, the IGBT allows current to flow between the collector and emitter.The resistance of the device causes it to generate heat.This is known as conduction loss.In addition, during switching, when the IGBT transitions between the ON and OFF states, the energy is temporarily stored and then released as heat, which is known as switching loss.These losses are intrinsic to the IGBT function and vary with the switching frequency as well as the operating voltage and current.In order to reduce these problems, it is essential that we need effective thermal management solutions.

Effect of overheating on IGBT performance and lifetime

Excessive heat accumulation in IGBTs can adversely affect their performance and longevity.High temperatures can cause a variety of problems:

Thermal stress:High temperatures can stress semiconductors.This stress can lead to mechanical failures such as cracks or delamination.

Reduced efficiency: As the temperature increases, the efficiency of IGBTs decreases.This will affect the performance of the electronic systems in which it is used.

Reduced lifespan: High temperatures can accelerate IGBT aging.This significantly shortens its useful life.Components may fail prematurely due to material degradation or internal device junction failure.

Liquid cooling system basics

Liquid cooling is an advanced method of managing heat.It is widely used in many fields.Applications range from high-performance computing to industrial machinery and electric vehicles.This method is particularly suitable for components such as IGBTs.They need to dissipate heat well to keep them working for a long time.

Components of a typical liquid cooling system

A typical liquid cooling system consists of several key components, each of which plays a vital role in thermal management:

Coolant: Coolant is the fluid in a system.It absorbs heat and takes it away from the parts.Common coolants include water and glycol-aqueous solutions.There are also some specially designed liquids.They have the best thermal properties and corrosion resistance.

Pump: The pump is responsible for circulating the coolant through the system.It ensures a stable flow rate, which is essential for efficient heat transfer across all parts of the system.

Radiator: Radiator facilitates heat exchange between the coolant and the external environment.As the heated coolant flows through the radiator, the heat escapes into the air with the help of a fan or natural convection.

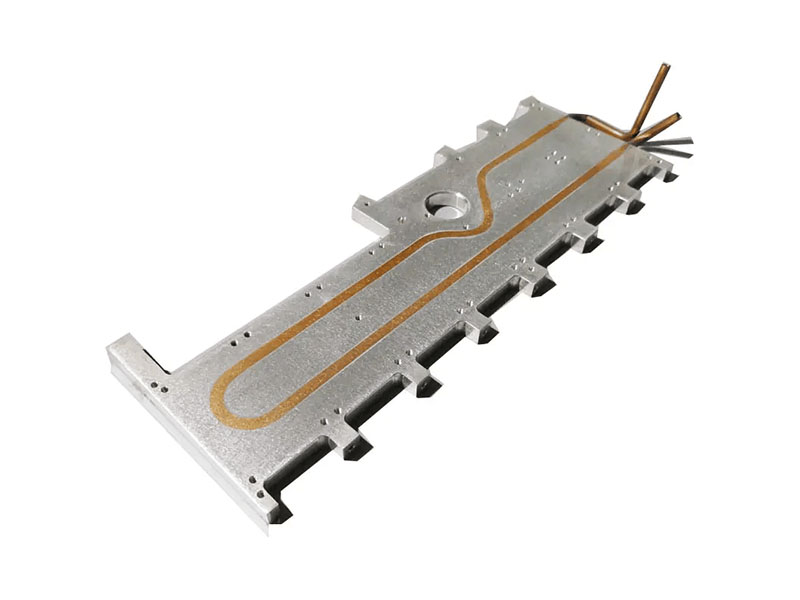

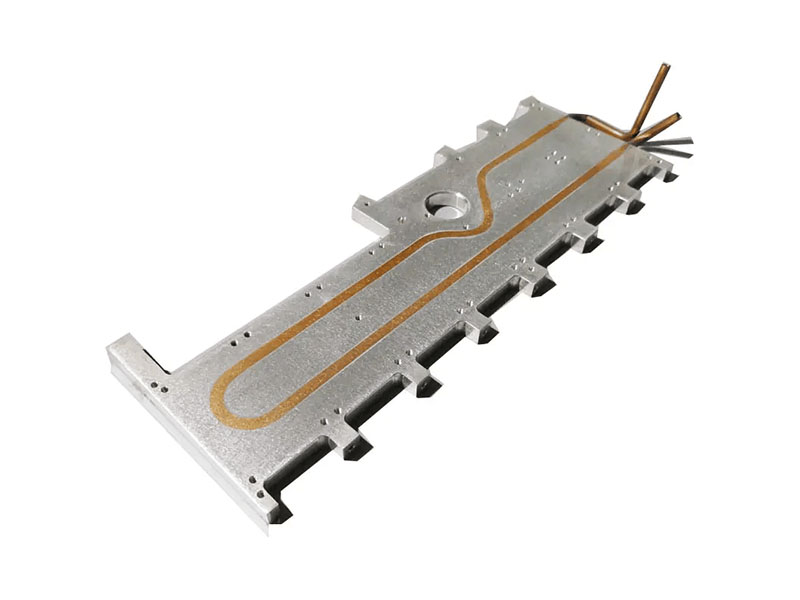

Heat exchanger: This component is connected directly to a heat source, such as an IGBT.The heat exchanger transfers heat from the IGBT to the coolant.The design and materials of the heat exchanger are crucial.They maximize heat transfer and minimize thermal resistance.

By combining these components together, the liquid cooling system can effectively manage the heat of the IGBT.It keeps the IGBTs at the optimum operating temperature.This improves the performance and reliability of the system.

Advantages of liquid-cooled IGBTs

Liquid cooling systems offer great advantages over air cooling, and they are particularly good at managing the heat of insulated gate bipolar transistors (IGBTs).They can maintain the performance, efficiency, and longevity of devices that rely heavily on IGBTs.Examples include electric vehicles and renewable energy converters.Here are the main advantages of using liquid cooling for IGBTs:

Superior heat dissipation: Liquid cooling is better than air cooling.This is because liquids can hold more heat and carry away heat better than air.The coolant in a liquid cooling system can absorb and carry more heat away from the IGBT more quickly.Fast heat dissipation is key.It prevents heat build-up that can lead to overheating and malfunction of IGBTs.This is critical in high-power or high-frequency operation.IGBTs are subject to enormous thermal stress.

Consistency in temperature control: Liquid cooling allows for more stable temperature control of critical components.Air can be turbulent resulting in changes in flow velocity and uneven cooling.In contrast, liquid cooling provides a stable, uniform flow of coolant in direct contact with hot surfaces.This consistency helps keep IGBTs within a narrow temperature range.This makes them more efficient and reliable.The ability to keep the temperature stable is very useful.This is especially useful in applications that require precise thermal management.Achieving optimal performance and avoiding heat-related performance variations requires management.

Type of coolant used for IGBT liquid cooling

In IGBT liquid cooling, the choice of coolant is crucial.This is due to different thermal characteristics, environmental influences, and operational needs.Water is the most cost-effective and has excellent thermal conductivity, resulting in excellent heat dissipation.However, water corrodes metal parts and is limited by freezing and boiling points.Ethylene glycol solutions, such as ethylene glycol or propylene glycol mixed with water, can prevent freezing.They also contain corrosion inhibitors.Therefore, they are suitable for use in cold places.However, they have a worse thermal conductivity than water.They can be poisonous, so they need to be handled with care.Specialty fluids are manufactured to meet specific needs.These include non-conductive or fire-resistant.They offer customized solutions for advanced use.Usually the price is higher.Due to its unique chemical composition, there are special handling and disposal requirements.Each coolant has its pros and cons.Careful selection is required based on the specific needs of the system.

Design considerations for IGBT liquid cooling systems

There are several key factors that must be considered when designing a liquid cooling system for IGBTs.They ensure efficient thermal management and system integration.These considerations include the flow rate of the coolant.They also include the system layout and how the cooling system fits with existing components.

Coolant flow rate: The flow rate of the coolant is crucial as it directly affects the efficiency of heat dissipation.The higher the flow rate, the better the cooling.However, this may require a higher power pump, resulting in more energy consumption.The optimal flow rate must strike a balance between effective heat dissipation and energy efficiency.

System layout: The layout of the cooling system includes piping, radiators, and heat exchangers.It must be set up with space and efficiency in mind.The layout should help to cool all IGBTs evenly.A short cooling path should also be maintained to reduce temperature differences in the system.

Integration with existing components: The cooling system must be matched to existing IGBT modules and other components.This includes installation considerations.Connectivity and compatibility with electrical and thermal interfaces are also included.

Material selection: Choosing the right material for your cooling system components is crucial.This includes the type of metal used in the heat exchanger and the composition of the coolant.The right materials can prevent corrosion, ensure durability, and maintain high thermal conductivity.

Conclusion

Liquid cooling is an important advancement in IGBT thermal management.It can greatly improve the performance and reliability of electronic systems.The liquid cooling system manages the heat of the IGBT very well.They keep temperatures optimal, reduce thermal stress, and extend the life of these critical components.The liquid cooling system dissipates heat well.They also increase system efficiency.This allows IGBTs to operate at higher power densities without overheating.At Lori, we specialize in designing and implementing advanced liquid cooling solutions to meet the unique needs of each IGBT application.