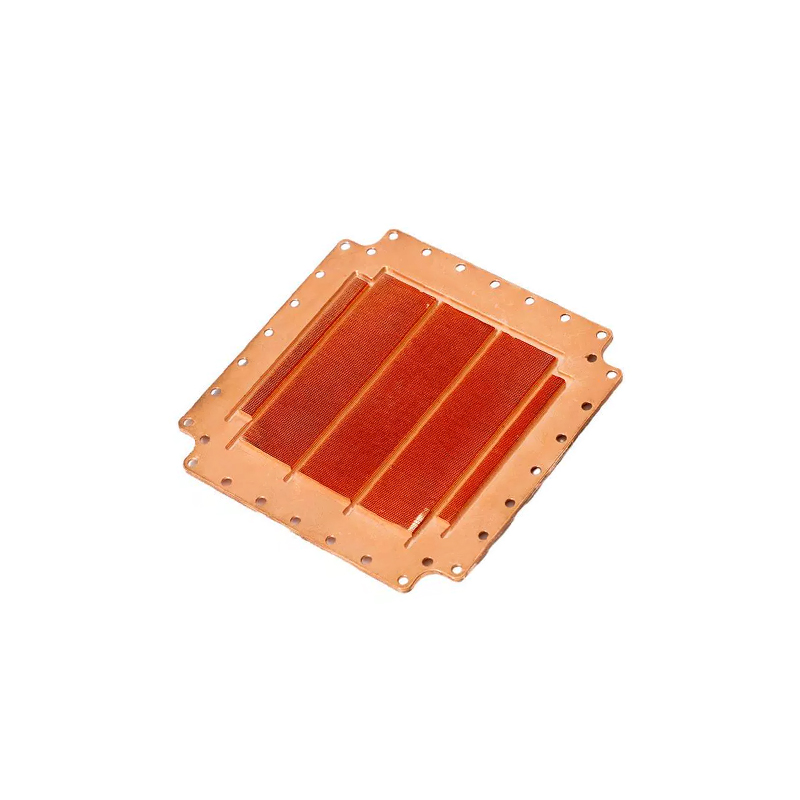

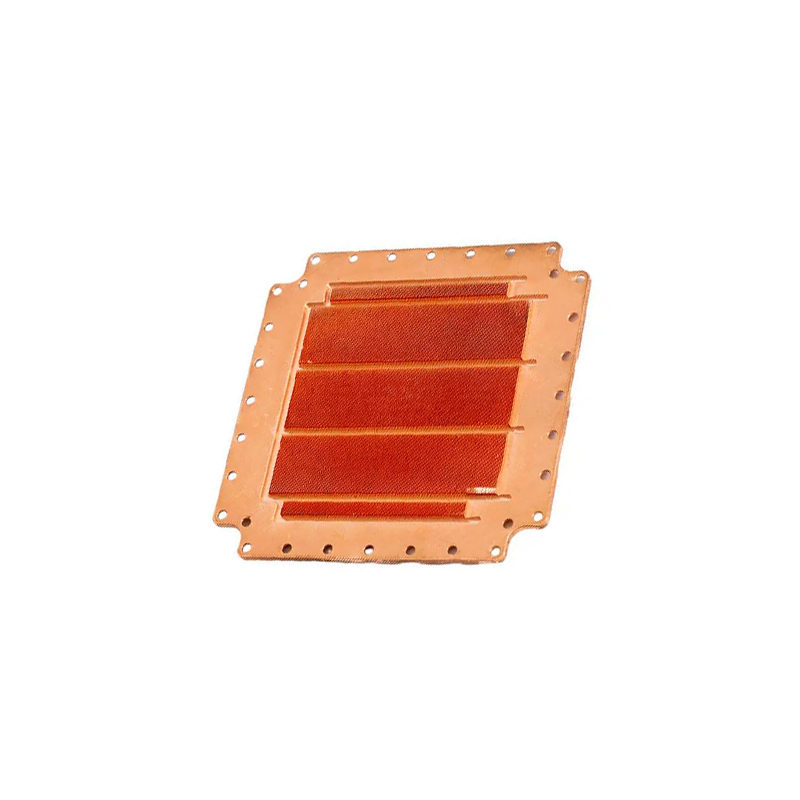

The skived fin heat sink has a high ,high density, ultra-thin fin and ultra-small spacing characteristic, which can increase the heat dissipation area per unit volume and improve the heat dissipation performance of the product.

2.Stable Thermal Conductivity

Compared with the skived fin heat sink, it has a one-time molding, stable thermal conductivity, no loss caused by the process and no risk of loosening and falling off, and the processing ability is increased in the later period, and the heat dissipation performance can be improved with buried copper pipes and other processes.

3.Higher Adaptability

It can meet the design requirements of large/ultra-small size high-power heat sink, and make up for the shortcomings of aluminum extrusion heat sink or extrusion heat sink structure.

4.System Stability

It can replace profile heat sinks, skived fin heat sinks, folding FIN heat sinks, die casting heat sinks, forging heat sinks.

5.Diversification of Structural Types

Can do single side skived fins, can also do double side skived fins, pipe four sides skived fins, skived ring fins, particular shaped fins, etc.