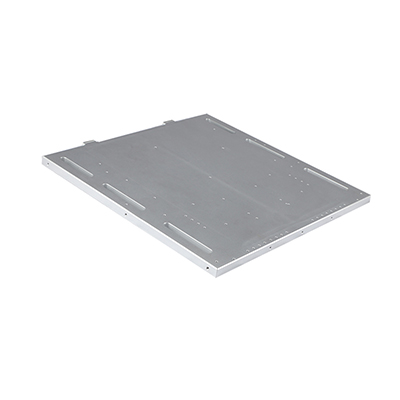

China Fiber Laser Vacuum Brazed and Friction Stir Welding (FSW) Liquid Cooled Plate

With the increase of high power heat dissipation demand, it is necessary to design efficient liquid cooled cold plate to solve the heat dissipation problem. Generally speaking, vacuum brazed and friction stir welding (FSW) technology aluminum liquid cooling plate is also a good choice. After CNC precision machining, the liquid cooled plate is welded by friction stir welding technology, which has high compressive strength and irregular water channels, which greatly improves the heat dissipation performance of the liquid cooled plate and can meet the heat dissipation requirements of different heat sources. The liquid cooling plate is made from 6061 aluminum alloy and features milled channels formed via friction stir welding (FSW) technology or using vacuum brazing.

The surface of the Fiber Laser vacuum brazed cold plates is with precision CNC machining to ensure flatness within 0.05mm and a surface roughness of Ra1.6.The size of the fiber optic guide slot is 0.8x0.6mm, and the surface roughness is Ra0.8.