Direct liquid cooling to chip (direct-to-chip liquid cooling) is an advanced cooling technology designed for high-performance computing systems, especially for critical components with high heat content such as processors (CPUs) and graphics processing units (GPUs). This cooling method achieves efficient heat dissipation by applying liquid coolant directly to the surface of the chip, thus avoiding the limitations of traditional air-cooled systems that rely on fans and heatsinks. Through effective heat management, direct liquid cooling can significantly improve system performance and reduce energy consumption.

Direct Liquid Cooling to Chip Working Principle

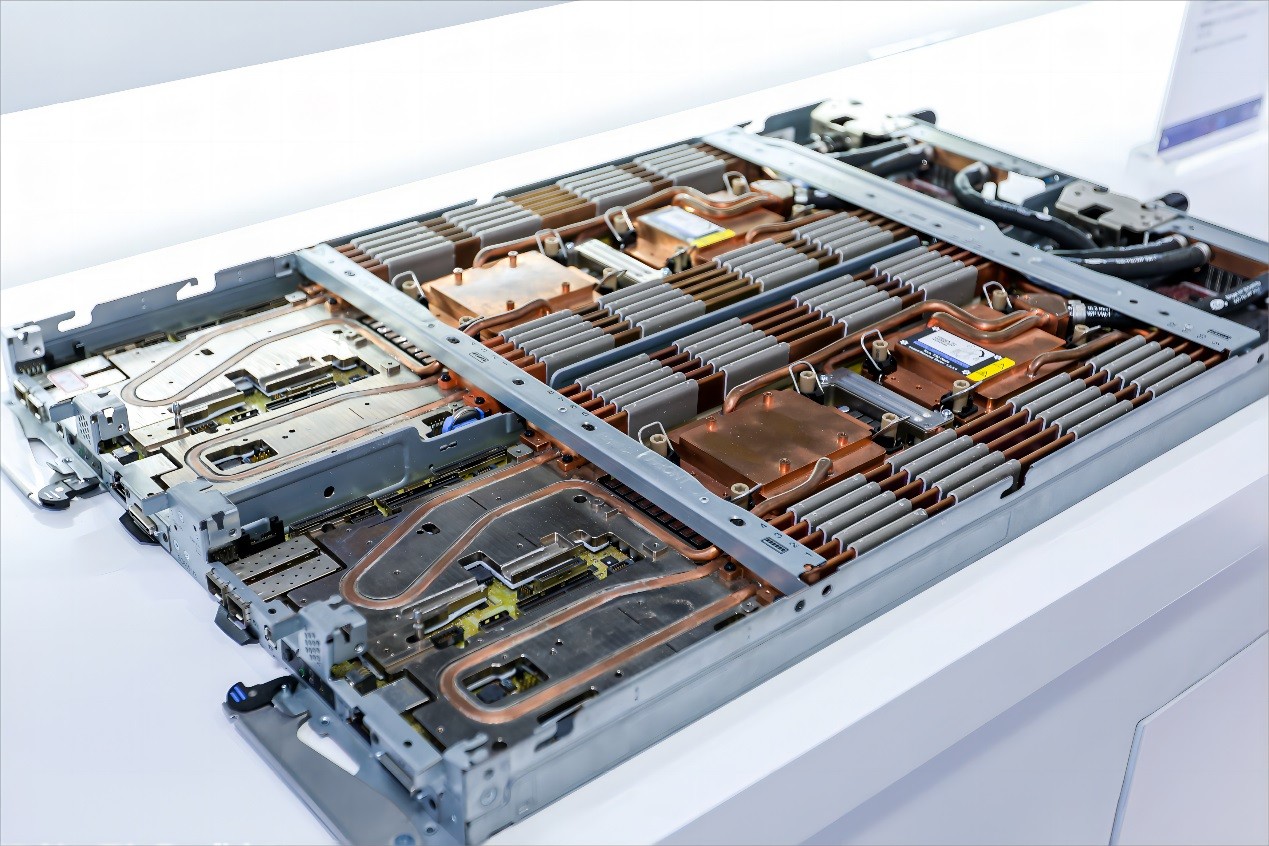

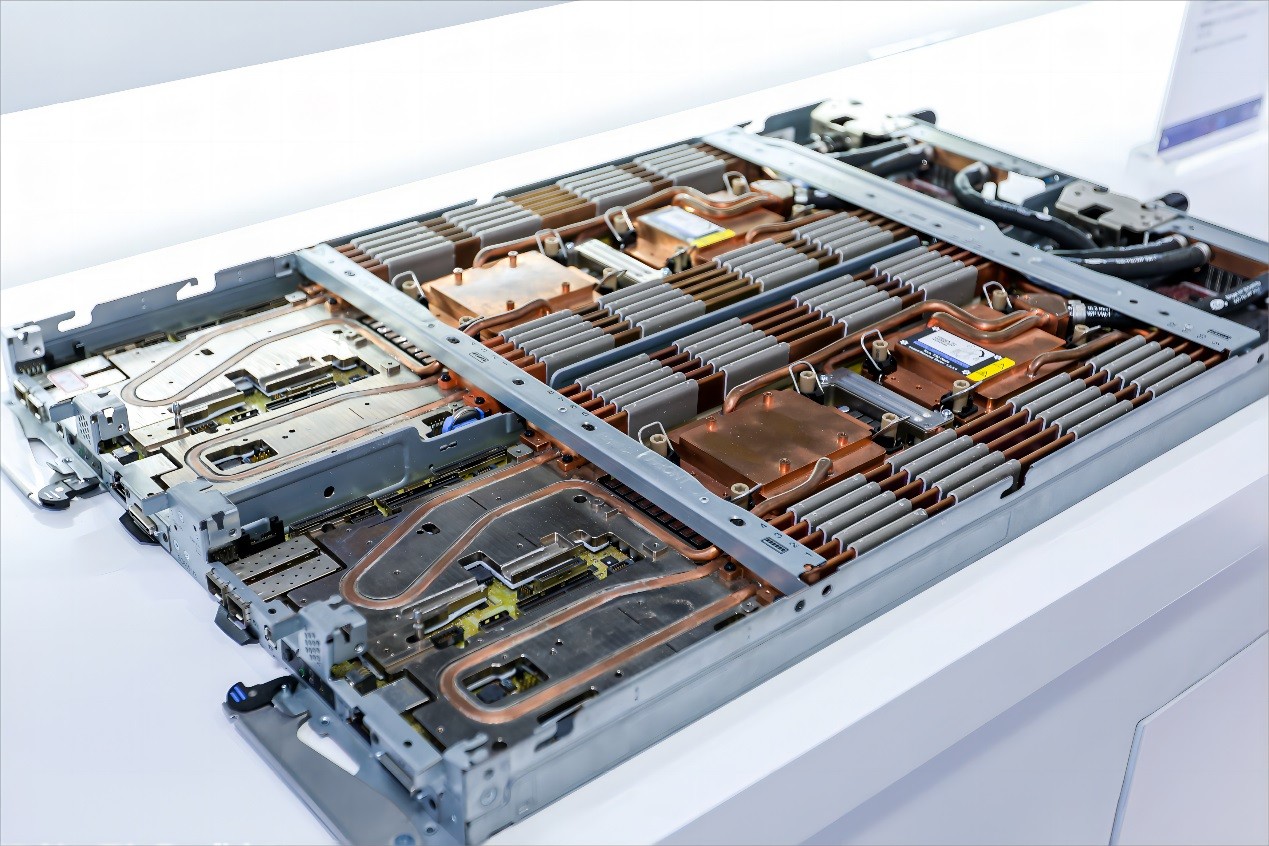

Direct liquid cooling technology achieves efficient thermal management through several key components. First, a cold plate is mounted to the chip surface, and coolant flows through channels inside the cold plate to directly absorb heat from the chip. The coolant is typically a special liquid with high thermal conductivity and low electrical conductivity, which allows for rapid heat removal while ensuring safety. The pump then circulates the coolant to the system's heat exchanger, which transfers the heat from the coolant to an external cooling source (such as a heat sink or cooling tower), completing the cooling process.

Advantages of direct liquid cooling to the chip

The main advantage of direct-to-chip cooling is that it dissipates heat faster and consumes less energy than traditional cooling systems in data centers, such as those that circulate cold air through server racks.

Instead of targeting a specific heat source, traditional air cooling systems blow cold over the entire array of equipment. Most of the air flows over components such as network interfaces and motherboard peripherals, which are not the primary source of heat generation. This means that the cooled air is effectively wasted.

In contrast, direct chip cooling systems can pinpoint specific components that generate heat. As a result, they can dissipate more heat with less energy, and from a sustainability perspective, the better the system's thermal performance, the lower the risk of IT failure due to overheating.

Direct Liquid Cooling to Chip Application Scenarios

Direct liquid cooling technology is particularly suited to high-density, high-performance computing environments such as data centers, high-performance computers (HPC), and large servers. In these areas, chips need to work continuously and efficiently, and traditional air-cooled solutions are often unable to meet the heat dissipation requirements. As a result, direct liquid cooling provides a more efficient and energy-saving cooling solution.

In data centers, especially those running cloud services, direct liquid cooling can help manage the heat load generated by large numbers of servers while reducing operating costs. Liquid cooling technology also ensures stable system operation in applications that require ultra-high processing speeds, such as high-frequency trading platforms.

Challenges of Direct Liquid Direct-to-chip Liquid Cooling

Cost: The implementation and maintenance costs of direct-to-chip liquid cooling systems are largely higher than those of cold air systems, which require more expensive and complex components.

Risk of Leakage: Fluids within direct-to-chip liquid cooling systems can leak. Since the fluid is not electrically conductive, leaks usually do not pose a significant threat to IT equipment. However, this can lead to cooling system failure, which can lead to overheating.

Environmental Impact: The fluids that pass through direct-to-chip liquid cooling systems are typically not environmentally friendly, which means that there is a risk of contamination in these systems.

Uncooled Components: Since direct-to-chip systems only cool the main heat source, there is a risk of overheating other parts of the server (e.g., hard disk).