As electronic products become more advanced, requiring more functions and higher reliability, excessive heat remains a major barrier to developing better-performing next-generation applications and breakthrough innovations. Every industry, especially mobile, medical, telecommunications, and the Internet of Things, is developing new products and systems that need to be lightweight, multifunctional, and capable of managing high thermal loads with high reliability. Engineers find it challenging to manage heat effectively as consumers demand smaller, thinner, more powerful devices with more options, functions, and capabilities.

Phase-change cooling is rapidly evolving and becoming increasingly popular in addressing these issues. Heat pipes are particularly suited for heat dissipation, providing faster heat spreading, lightweight design, higher reliability, and longer lifespan. However, the most significant advantage of heat pipes is their design flexibility, allowing them to be easily integrated into thermal systems, thereby greatly improving cooling efficiency and capacity.

Overview

Heat pipe components combine the mature and reliable passive two-phase heat transfer with various other thermal management technologies to produce effective, durable cooling solutions. For over a decade, Lori has been innovating and manufacturing heat pipe solutions. Our experience enables us to design and manufacture effective and durable cooling solutions that can operate in the most demanding environmental conditions.

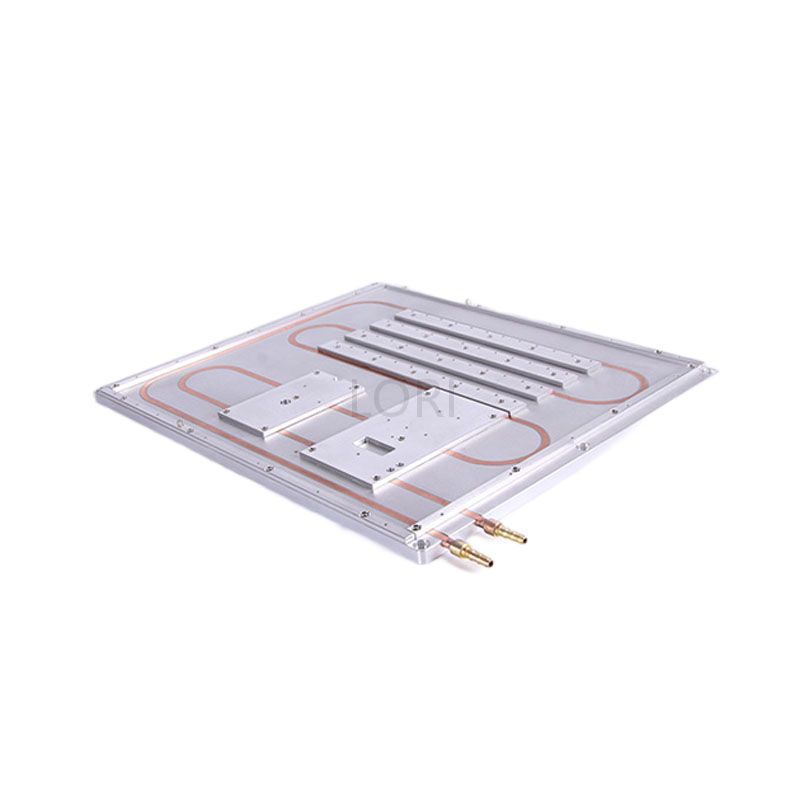

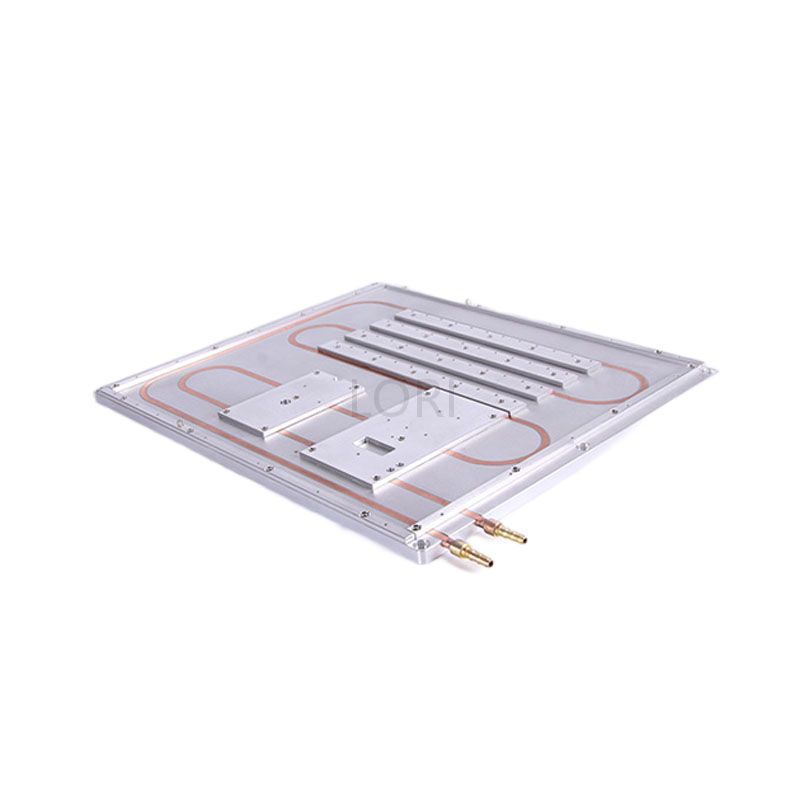

Expandable copper walls and wicks can be bent or flattened to meet the thermal and geometric requirements of applications. This can be used to reduce overall size, increase surface contact, or arrange heat pipes around mounting hardware. Heat pipes can be embedded into other technologies to accelerate heat dispersion or use heat pipes within systems to transport heat from heat sources to locations where it can be safely dissipated.

Misconception 1: If heat pipes fail, they will leak liquid onto my electronic device.

Truth: Heat pipes rarely (if ever) rupture. In extremely unlikely cases, a very small amount of liquid inside the pipe will be completely saturated into the wick and cannot drip or leak onto your electronic device.

Heat pipes are inherently robust, being purely passive systems with no moving parts that wear out over time. To “break” a well-manufactured heat pipe, you would need to cut the pipe or excessively bend or fold it. Heat pipes are filled with a vacuum during manufacturing, ensuring that the fluid inside always exists in vapor form and thus does not drip.

Their durability, higher reliability, and leak-proof nature make heat pipes ideal for markets where traditional liquid solutions could cause catastrophic consequences, such as aerospace, medical, consumer electronics, and high-power applications requiring high reliability.

Misconception 2: Heat pipes are heavy.

Truth: Heat pipes can reduce the overall weight of the components more than they add.

While they are often made of copper (a relatively heavy material), some believe that integrating heat pipes will add weight to their solutions. Although heat pipes are made of copper, they are hollow and can reduce the weight of the solution while improving thermal performance in multiple ways. Heat pipes are often used to transfer heat to cooler, more remote, and open areas within a device, where airflow and space are better, allowing for the addition of fans and lightweight fin structures to reduce the overall size and weight of the cooling solution.

Another common example is replacing traditional copper heatsinks or larger heatsinks with aluminum-based heatsinks with embedded heat pipes. The high thermal efficiency of heat pipes can evenly and quickly distribute heat across the entire heatsink, improving heatsink efficiency and reducing the size and material required, thus lowering the overall weight and cost of the solution.

Misconception 3: Heat pipes can only be used with evaporators and condensers at both ends.

Truth: Heat pipes work along the entire length of the pipe, regardless of their position on the pipe, consistently transferring heat from the hotter to the cooler area.

Heat pipes are typically designed as thermal management components to transfer heat from a heat source at one end to a safe and effective dissipation point at the other end. This is a common usage but not the only way to use heat pipes.

The wick structure of heat pipes allows them to work in any orientation and typically spans the entire length of the pipe. Heat naturally moves from hot to cold, and heat pipes do the same. Regardless of where the heat is applied along the pipe, it always moves from the heat source to the condensation point and then returns through the wick. This increases design flexibility and heat pipe usage options, allowing for more innovative and cost-effective thermal management. One such use is embedding heat pipes to spread heat rather than transfer it. When heat pipes are embedded in the base of a heatsink, heat will condense along the entire length of the heat pipe rather than a fixed area. For example, integrating heat pipes into air-cooled heatsinks extends high-power performance, reducing the need for liquid systems when cooling high-power IGBTs.

Misconception 4: Heat pipes can only spread heat in a straight line. If I want to spread heat across the entire base, I need a heat spreader.

Truth: Heat pipes can be bent and used similarly to heat spreaders, but with a more integral structure.

When heat pipes were initially introduced and began to be integrated with other technologies, they were embedded in straight lines. To achieve more even heat dissipation, engineers used heat spreaders. While heat spreaders effectively achieve uniform heat distribution, they come with their own set of design challenges that may not suit every application.

Although heat pipes only move heat along their axis, this axis can be bent or used with multiple heat pipes to effectively serve as a plane spreading mechanism similar to a heat spreader. Heat pipes are cheaper, have greater structural integrity, and can be designed to mimic the function and performance of heat spreaders. When properly embedded, heat pipes can withstand considerable mounting forces in applications where vapor chambers may be too fragile.

Misconception 5: Heat pipes need to be very hot to work.

Truth: Manufacturing techniques allow heat pipes to operate even with very small temperature differences.

Because heat pipes rely on evaporation and condensation to operate, there is a common misconception that a large temperature difference or high temperature is required to benefit from using heat pipes. However, since heat pipes are filled with a vacuum before sealing, the fluid inside exists in both liquid and vapor forms at its saturation point. This is similar to boiling a liquid at lower temperatures under reduced pressure at higher altitudes. Molecules require less heat to be excited to convert from liquid to vapor. Therefore, the temperature of the heat source does not need to reach the standard boiling point to induce the phase change from liquid to gas. In fact, only a few degrees of temperature difference between the "hot" and "cold" regions of a heat pipe are needed for it to function. This is one of the main benefits of using heat pipes as it minimizes the thermal resistance of the solution.

Misconception 6: Heat pipes cannot be used in freezing conditions.

Truth: Heat pipes can be designed to work under extremely harsh conditions, including freezing environments.

The operational behavior of heat pipes under environmental conditions depends on the materials and design used. While copper/water is the most popular combination, other materials can be used based on specific requirements. Liquids like ammonia, methanol, and acetone can be combined with compatible metals to create heat pipes that operate at temperatures far below -60°C.

Misconception 7: Heat pipes are expensive.

Truth: Adding heat pipes can reduce the overall cost of the solution.

The ductility of copper allows for economical manufacturing of heat pipes, reliable sealing, and easy bending and shaping into specific geometries. Lori has developed manufacturing processes and heat pipe technologies to produce cost-effective copper/water high-performance heat pipes. Heat pipes allow engineers to use aluminum-based and embedded heat pipes in applications that require copper fin bases, thus reducing costs. They can also eliminate the need for fans or other components, saving both money and weight.