140mm Pin Heatsink advantages:

1. 140mm pin heat sink is cold forged heat sink which made of pure aluminum, and it has high thermal conductivity and rapid cooling, thermal conductivity is 226W/M.K, conduction effect is obvious.

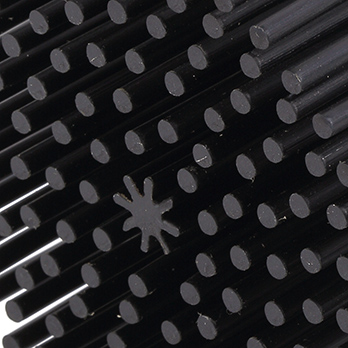

2. Outer diameter of bottom base is 140mm Scientific layout, reasonable structure, Circular progressive layout with equal proportions, 3mm cylindrical heat sink, evenly distributed,Reasonable structure, durable mold,Same gap, good air flow.

3.The thickness of the bottom plate is 10mm and the height of the column is 60mm; Integrated structure, low thermal resistance, high efficiency; Small temperature difference of conjoined structure, controllable temperature difference of the whole; Compatible with multiple surface treatments, color customization.