Application and processing status of liquid cooling radiator

In the power and electronic industries, high-power devices are prone to problems such as burning down or overheating, which may lead to unstable performance. It is often necessary to configure a radiator to cool them down.

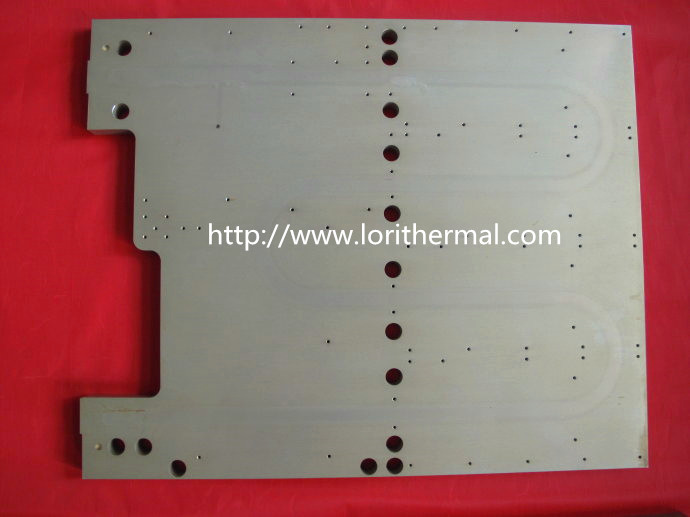

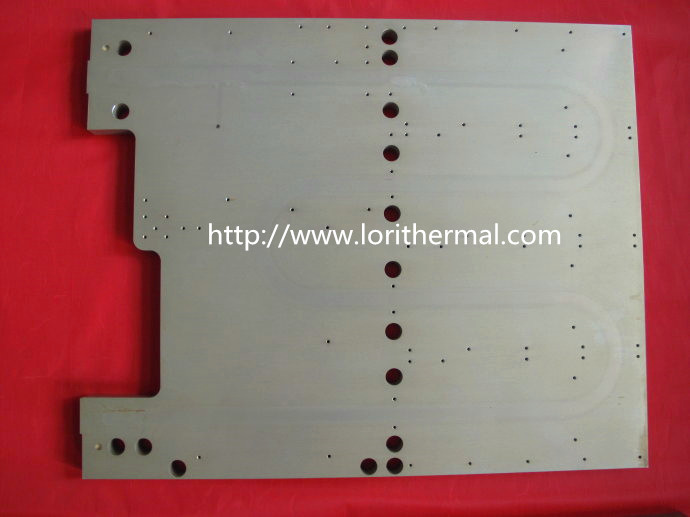

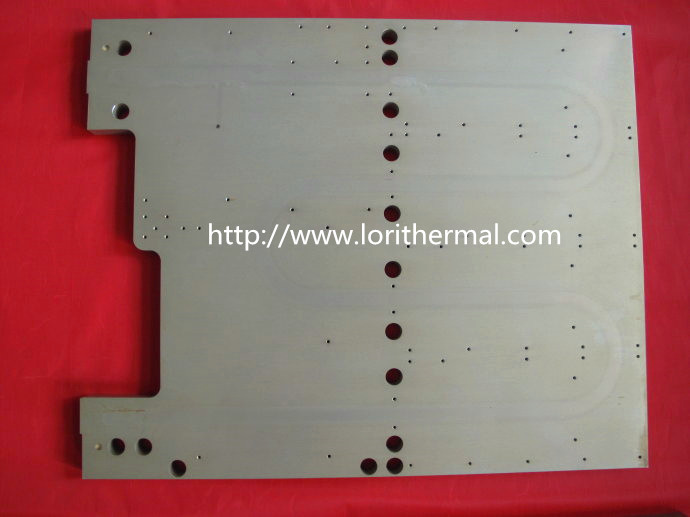

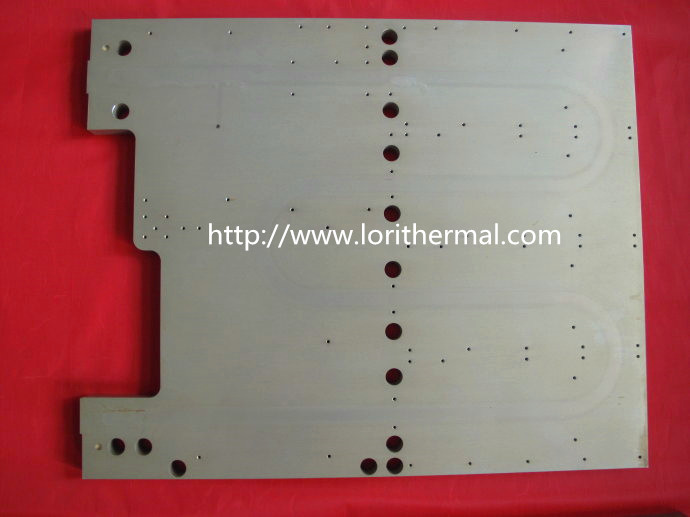

The traditional radiator is made of copper, aluminum and its alloy.Due to the requirement of welding deformation and surface assembly, there should be some machining allowance on the surface after welding.

It is difficult to use traditional welding or brazing in order to achieve good sealing and certain compressive strength after processing at the same time.It is easy to occur solder block channel or solder loss of weak joint welding defects.

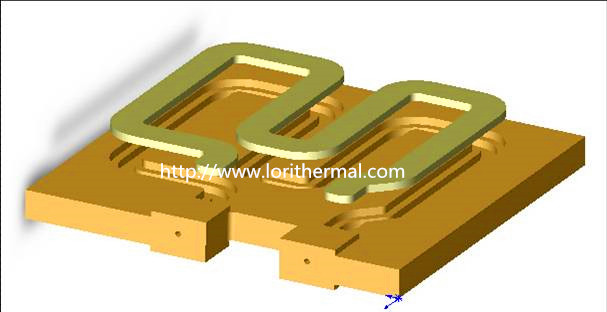

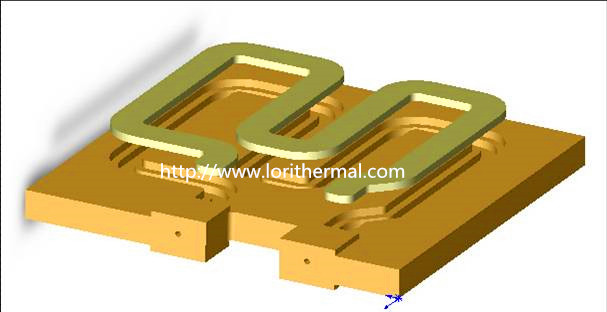

FSW manufacturing radiator advantage

1. It is a solid state welding technology, do not need filler, with excellent joint performance.

2. Good adaptability to aluminum, copper, magnesium and other nonferrous alloys that are difficult to weld or cannot be welded by traditional welding methods;

3. This method has a high degree of automation, weld consistency and excellent sealing performance;

4. The technology will be very suitable for aluminum or copper liquid cooling radiator welding.

Product design requirements: 2MPa for 15 minutes without leakage;

FSW post-welding test: 4MPa lasts for 20 minutes without leakage, greatly exceeding the design requirements.

According to the theoretical calculation, for the internal waterway structure of 15mm wide cover plate, the effective welding depth of 1mm FSW can withstand the internal pressure of more than 10MPa.

All aluminum alloy products involved in connection can be connected by friction stir welding process.For aluminum alloy welds welded by friction stir welding process, under the condition of no groove opening and no filaments filling, the base material is plasticized directly by solid-phase connection method and recrystallized under the pressure of stirring head forging. The grain size of the welding seam is less than an order of magnitude of the base material, and the various properties of the welding seam are close to the base material.Perfect realization of aluminum alloy connection.

Technical characteristics of friction stir welding

Friction stir welding (FSW) is a process for the connection of aluminum alloy, copper alloy, magnesium alloy, titanium alloy and other non-ferrous metals.The technical features of friction stir welded aluminum cooling technology are as follows:

1, direct welding of the base material, do not need to bevel, do not need to fill wire;

2. It is not necessary to remove the oxide layer of the material before welding, and there is no need for vacuum and protective gas during welding.No element burns after welding.

3. The grain structure of welding seam is forging structure.The crystal structure is isotropic. The properties are close to the base material.

http://www.lorithermal.com/liquid-cold-plate