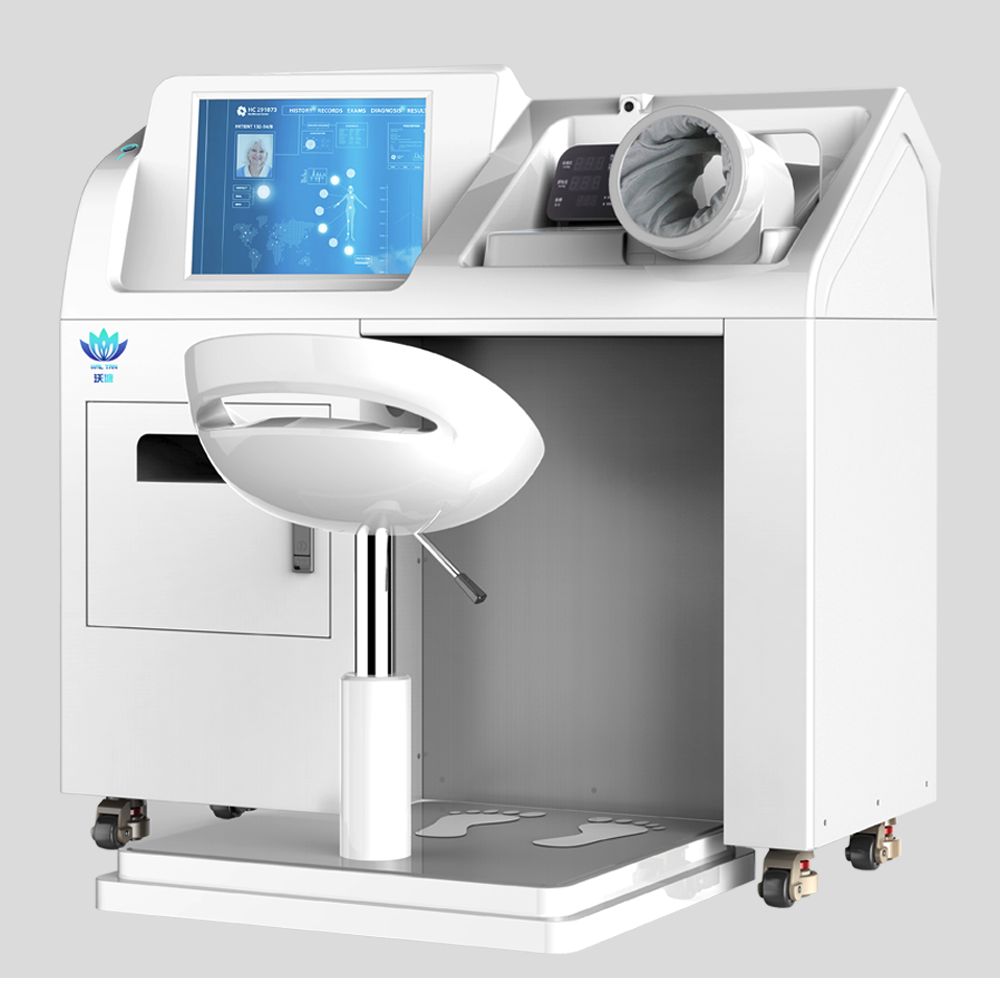

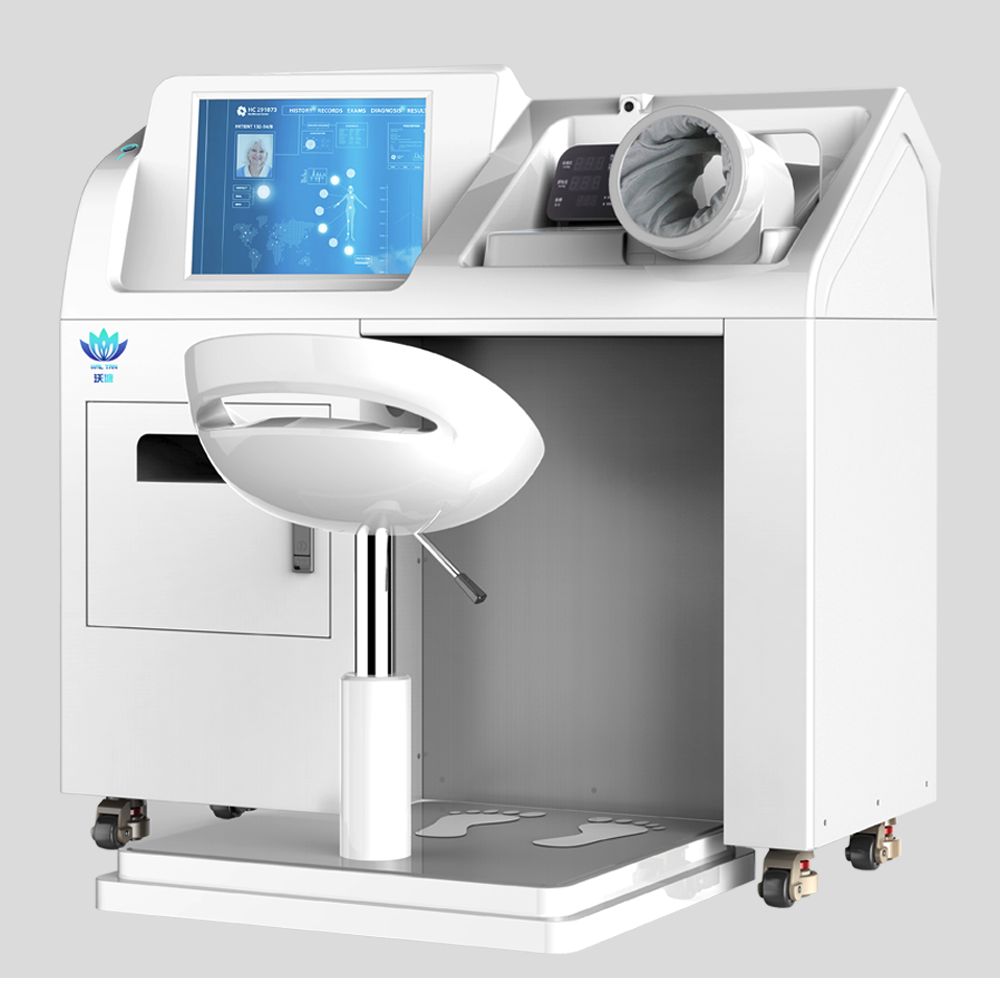

Electronic devices are increasingly being used in medical working.Their demands on the environment are more varied and strict, and temperature is one of the most important factors. Because temperature changes affect electronic devices the most. At present, aluminum extrusions and heatpipe heat sink and fans are commonly used. At high temperature, almost all parts of instruments and equipment are affected. The polymer material will accelerate the decomposition and aging at high temperature, shorten the life of electronic components, a good medical cooling system is very important for the ventilation and cooling of medical equipment.

During the normal use of medical equipment, due to the action of electric current, the internal (control box) of medical equipment has different degrees of temperature rise.If the temperature rises beyond the safe range in normal use (or long time use), install heatpipe heat sink and fan or liquid cooled plate cooling device (one or more sets) to ensure the normal operation of the equipment in the process of use and improve the safety of the equipment.Therefore, in the maintenance of medical equipment, maintenance should pay attention to the inspection of the cooling of equipment, in order to avoid the cooling fan work is not normal and lead to the circuit components overheating failure, affect the normal use of medical equipment and cause unnecessary economic losses.

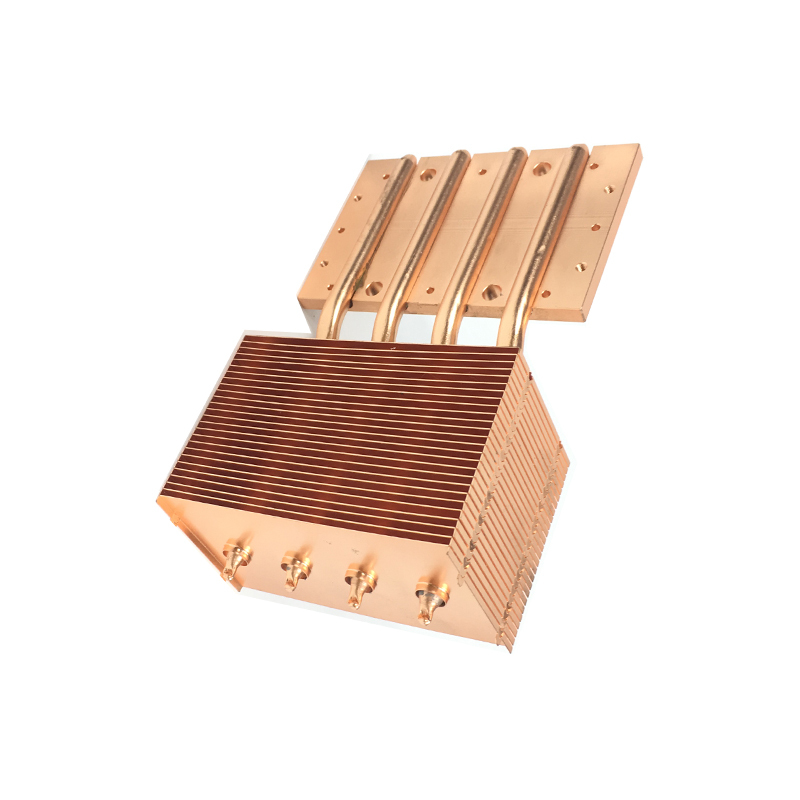

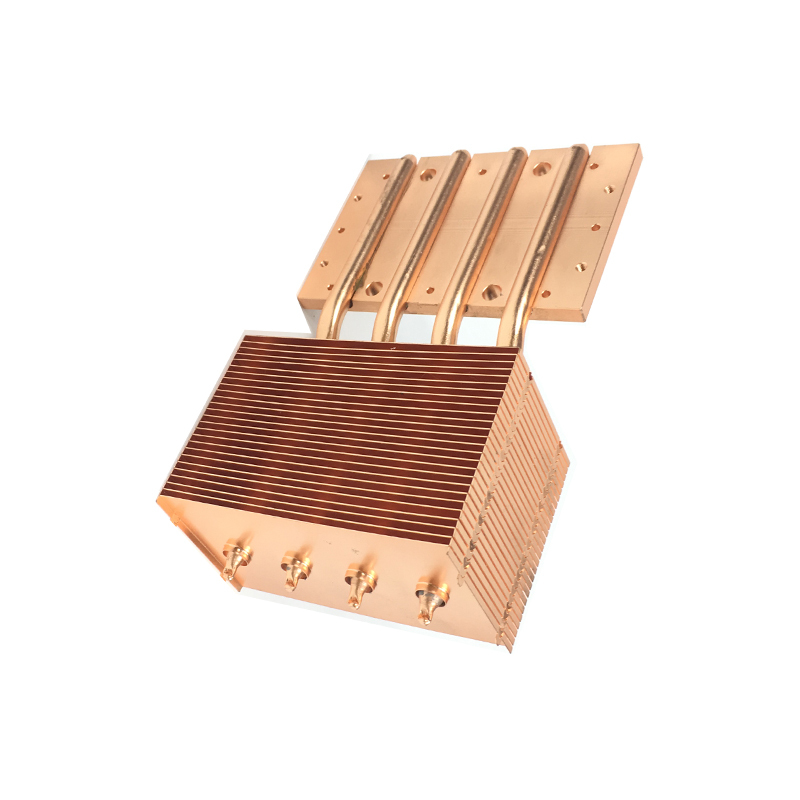

With the continuous development of electronic assembly technology, the volume of electronic equipment tends to be miniaturized and the system tends to be complicated, and the high thermal density has become an irresistible development trend.In order to meet the demand of high heat density, fans, heat pipe heat sink and other traditional means of cooling constantly innovate, new and efficient cooling methods emerge in an endless stream.In the face of numerous ways of cooling, it is very important to distinguish the cooling capacity of various ways of cooling, so as to select both economical and reliable methods of cooling.The covering type medical water cooling board can be better applied to chip cooling of all kinds of large medical instruments.Its use of full coverage of the watercourse cooling, cooling effect is more comprehensive, can effectively improve the cooling efficiency of about 60%, directly reduce the temperature of 30 degrees or more.In order to ensure the quality of their own products at the same time, cooling water cooling board also provides a reliable guarantee for the cooling of all kinds of large medical instruments and the extension of service life.

From imaging devices to surgical instruments to automated immunity, the power of 21st-century medical technology is impressive, thanks in large part to the power of microprocessors.For cooling engineers, however, these advances have come at a cost.The greater the power of the device, the greater the heat it generates and, in general, the smaller the space it has to dissipate.With the increasing demand for accuracy and reliability of medical equipment, cooling control becomes more and more important.Here we think that water cooling cooling will be a mainstream trend, accurate core cooling cooling water cooling plate, occupying a smaller area.liquid cooled plate control cooling remotely, reducing noise and improving cooling performance.

In the development of medical devices, passive cooling is mainly aluminum extruded heat sink and heat pipe heat sink. Passive cooling management is obviously a major factor to help ensure the accuracy and advanced functions of current medical devices, and further develop these capabilities.Passive cooling management scheme has very valuable advantages in saving space, reducing weight and reducing maintenance cost.Innovative cooling technologies are playing an important role in the future development of medical devices, as the increased functionality and computing power of electronic devices have been generating more heat that needs to be emitted, and miniaturization is gradually reducing the space for deploying heat management devices.

To sum up, the cooling of medical equipment will become more sophisticated. Obviously, the emergence of water-cooling cooling will be a perfect solution. With the popularity of liquid cooling, Lori will provide more water-cooling cooling solutions for various industries.