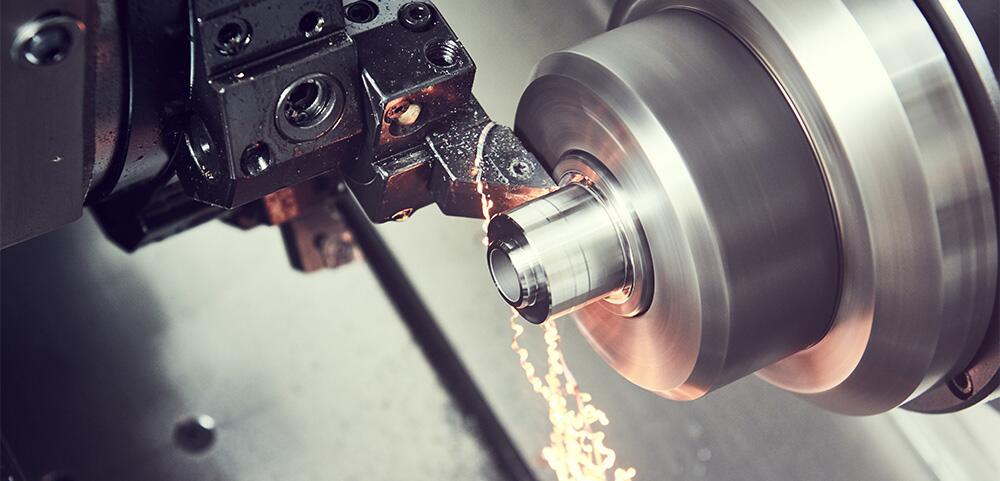

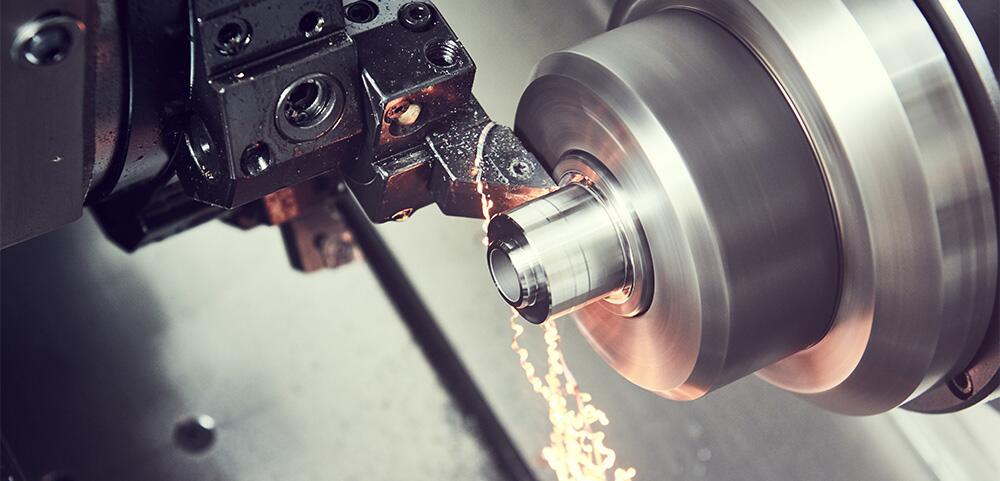

What is CNC Turning

CNC turning is the process of cutting materials to achieve a target shape and is classified as cutting. As a CNC turning manufacturer, Lori specializes in producing custom turned parts and precision CNC turned parts, utilizing various tools and processing methods to introduce the characteristics, processing sequence, and more of complex shape lathe processing.

CNC turning process is a kind of cutting processing. Cutting also includes milling processing and opening processing, but in lathe processing, the cutting tool contacts the rotating material, without needing to cut off the part while machining into the target shape.

CNC Turning is similar to CNC milling, which is also included in cutting, but differs in what is rotated. In CNC turning processing, the processed material rotates, whereas in CNC milling processing, the material is fixed, and the rotary cutting tool does the processing.

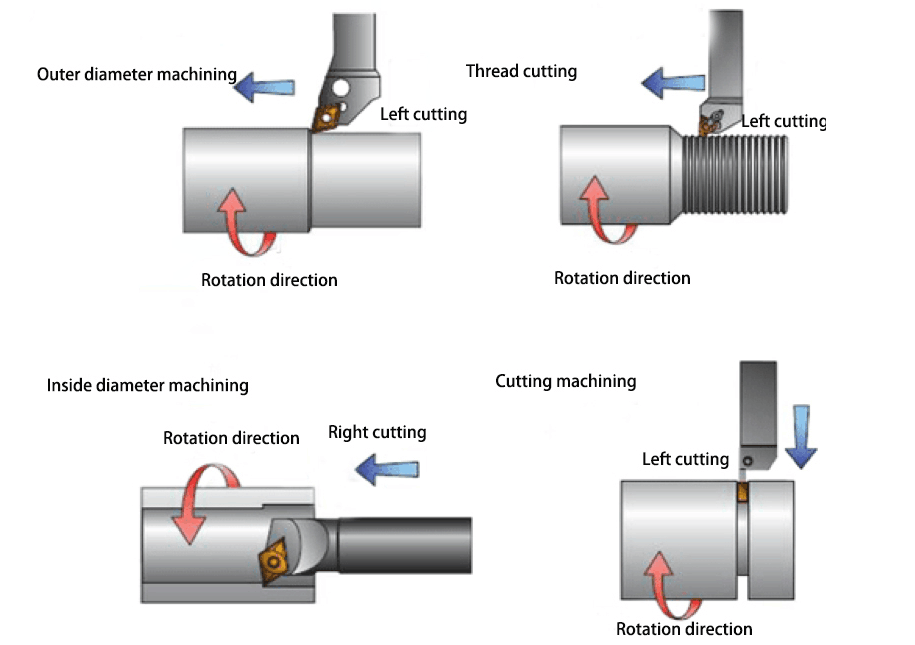

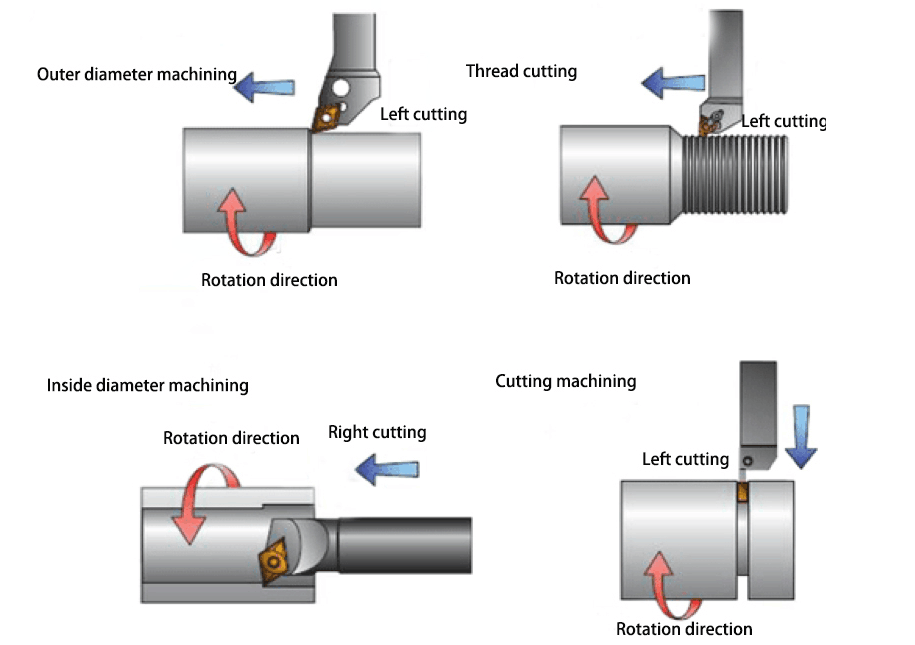

Basic machining methods of CNC turning

CNC lathe turning processing encompasses four basic processing methods: outer diameter machining, inner diameter machining, thread cutting machining, and cutting machining. The following describes each of these methods in detail.

Outer Diameter Machining

Contour machining involves making the cutting tool contact the outside of the rotating material. It is the most commonly used machining method in CNC turning, utilized for both surface finishing and rough cutting during the initial processing stages to achieve the target shape. When producing custom CNC turned parts, attention to detail is crucial to ensure precision.

During outside diameter machining, the resulting chips may become entangled in the cutting tool. For particularly high-precision finishing, the angle of the cutting tool must be adjusted to prevent chip entanglement and maintain accuracy.

Inside Diameter Machining

In inner diameter machining, the inside of a material is cut, thereby enlarging the holes created by opening machining. This method is used to adjust the size of the hole and enhance the appearance of the inner surface, essential for precision turned parts.

For inside diameter machining, the tool must be lengthened according to the depth of the hole to be machined. However, long cutting tools are prone to deviation, so careful attention must be paid to minimize accuracy reduction. Additionally, since chips accumulate in the hole, frequent removal is necessary.

Thread Cutting

Thread cutting is a machining method that generates threads. In CNC lathe turning, both external and internal threads can be processed using special thread cutting tools. This capability is one of the significant advantages of CNC lathe processing over milling and machining centers, which typically only allow for internal thread creation.

To achieve consistent pitch, the special tool for thread cutting must be in contact with the material, allowing the tool to move at a constant speed. An "automatic feed function" is often employed to maintain this speed.

Opening Machining

Opening machining involves pressing a drill against a rotating material to create a hole. This step is necessary before machining the inner diameter to allow special cutting tools to enter. Although the precision of drilling with a drill is not exceptionally high, it is typically used to prepare holes of the required size for subsequent finishing.

Cutting Machining

Cutting involves pressing a cutter against the material to remove unwanted parts, akin to slicing a cylinder into a circular shape. Precision and skill are required, as thin-bladed tools must be used, and vibrations and sounds must be monitored during operation. To perform high-precision CNC turning machining, measures such as employing flexible blades and using cutting oil are necessary.

At Lori, as a cnc turned parts manufacturer specializing in precision CNC turned parts, we strive to provide exceptional quality and attention to detail in every custom turned part we produce.