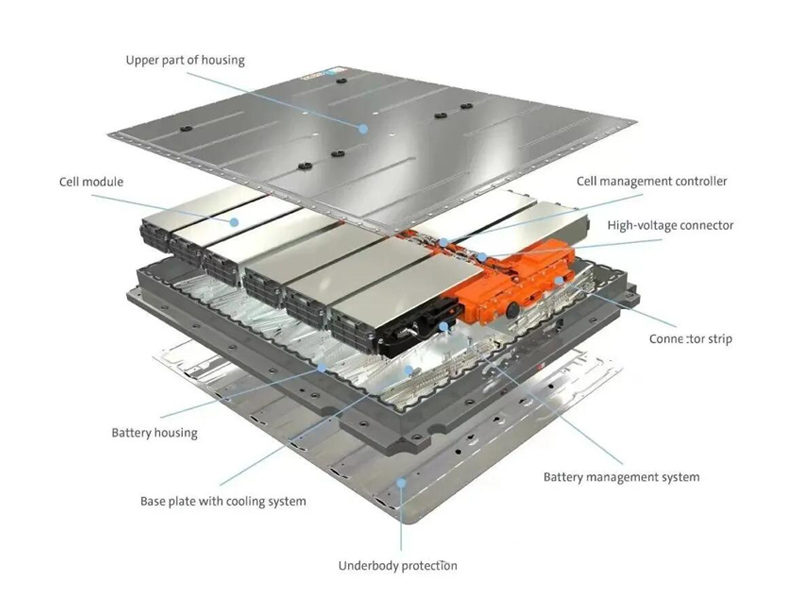

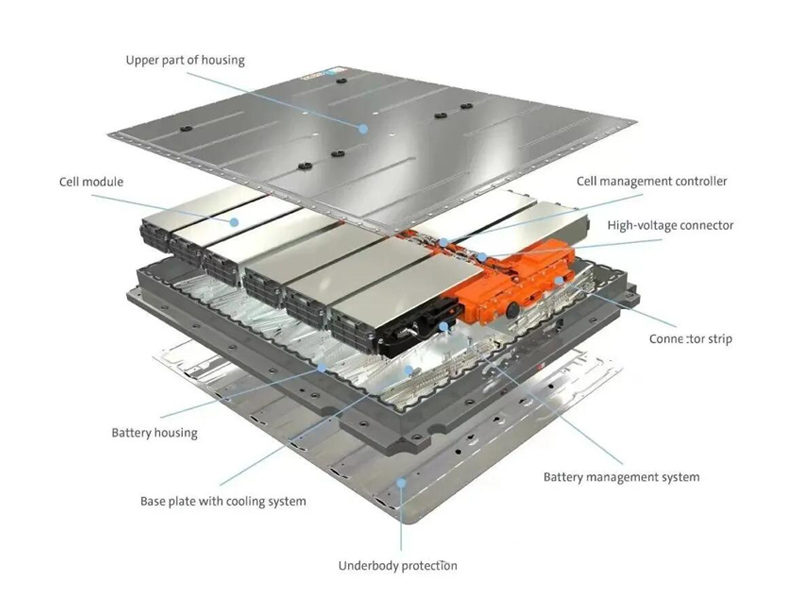

With the in-depth promotion of the national new energy steam thermal management, the new energy automobile industry has received more and more people's attention. Power battery as the heart of new energy vehicles, its safety, life, driving range, performance has also become the focus of attention of the majority of users. In order to improve the performance of the battery, extend the CFD calculation life, increase the driving range of the vehicle, and prevent safety accidents of the power battery, the operating temperature of the battery has become one of the key factors. In a number of battery cooling schemes, liquid cooling, with its large specific heat capacity and high heat transfer coefficient, has become the mainstream cooling method beyond air cooling and phase change cooling. The heat generated in the work of the power battery is transmitted through the contact between the electronic components and the surface of the plate aluminum device, and is eventually taken away by the coolant in the flow channel inside the device plate, which is the water-cooled plate. The design form of the water-cooled plate and its layout position are also varied, mainly according to the type of battery and the overall layout of the battery system. In addition, in order to ensure the temperature uniformity of large-energy battery packs, the entire thermal management system basically adopts multi-parallel branch design, and the longer the cooling channel, the more difficult the temperature uniformity control is. For example, the length of Tesla Model X single cooling pipe is about 5.2m, and the length of Model 3 single cooling pipe is about 1.9m. The overall uniformity of the battery system has been greatly improved.

Technological change of battery water cooling plate

From the early ordinary oil to electricity, to the optimization of the battery PACK program under the cost reduction requirements, the water-cooled plate process route is also undergoing changes.

1. The initial product - extruded aluminum water-cooled plate

The material used for the water-cooled plate is a 6-series aluminum profile with a plate thickness of about 2mm, without using the suspension design, directly take the VDA module to pile up, each place 3-4 modules, you can also integrate the water channel into the bottom of the box, all modules are stacked on the water-cooled plate, the strength can be seen.

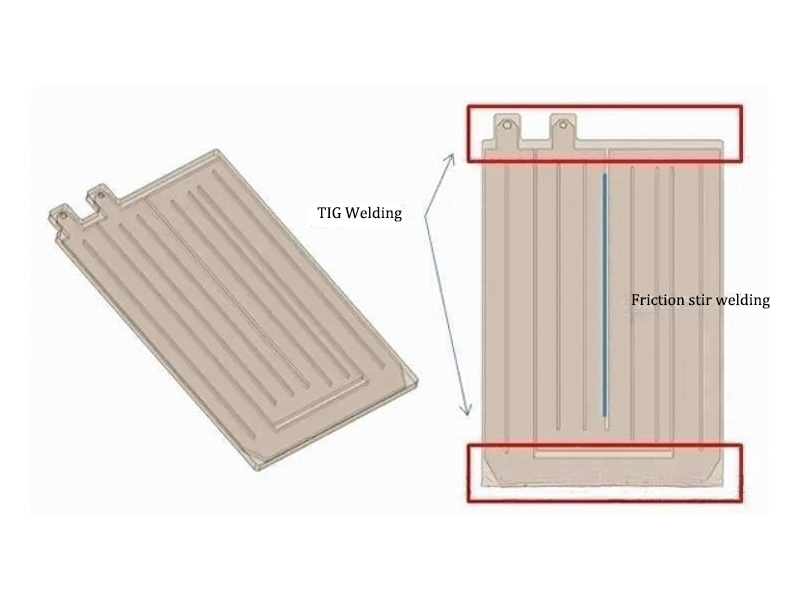

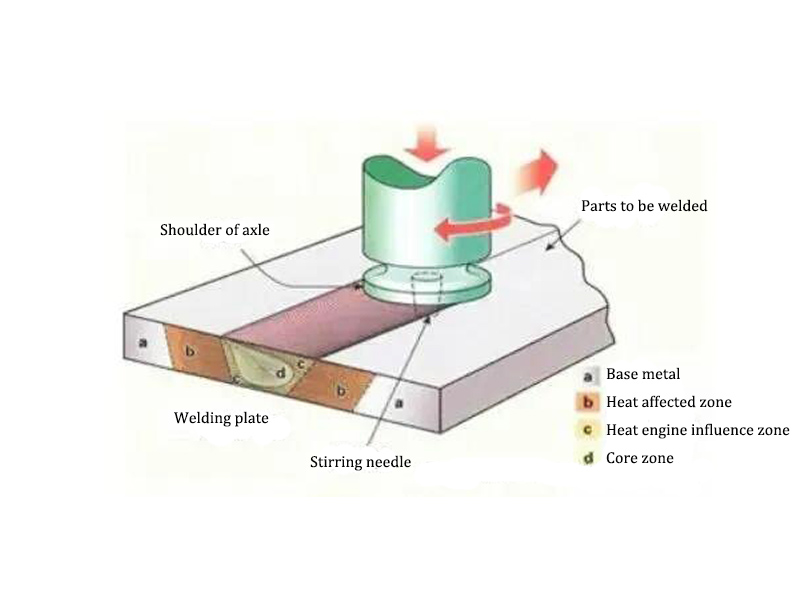

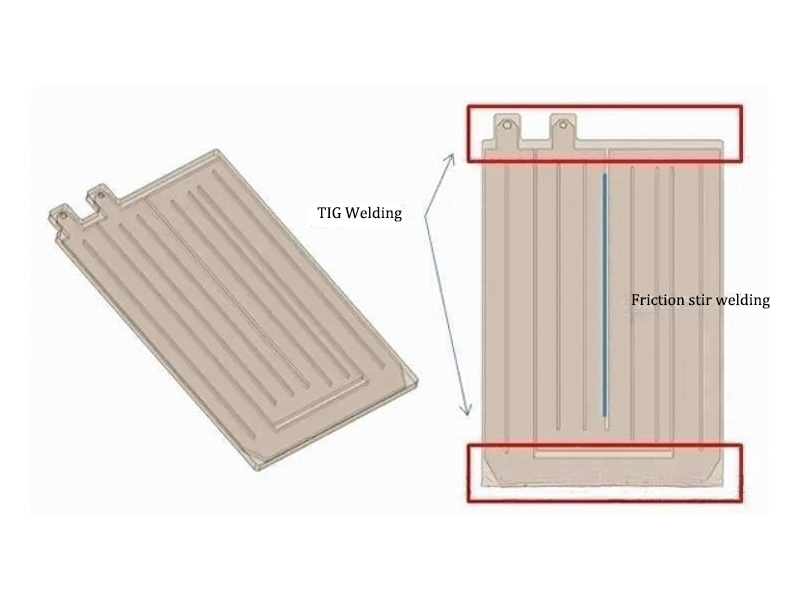

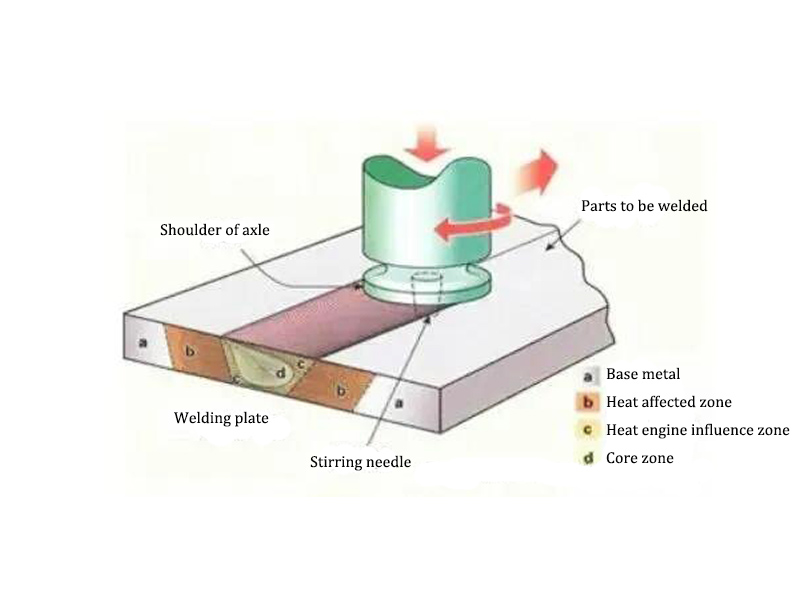

However, the forming process of this cold plate is more complex, if you want to make a large board, because there is not such a large mold, you need to put two to three boards together with friction stir welding, in addition, the type of water-cooled plate at both ends of the plug need to be welded to form an internal water loop, so the overall process is more and more complex, plus the welding head is also a consumable, so the cost is higher.

2. Second generation products - small stamping plate and harmonica tube

The performance of the water-cooled plate will affect the performance of the power battery, which directly affects the endurance of the electric vehicle, and the extruded aluminum water-cooled plate several boards of ten or twenty kilograms of fluid limit the play of the battery, so it is directly into the cold palace. Subsequently, the market turned its eyes to more lightweight stamping plates and harmonica pipes, and the water-cooled plates of the brazing process entered the historical stage. First of all, brazing this process, in fact, brazing in the automotive industry is widely used and mature, the front end of the car radiator, condenser and plate heat exchanger are used in this process, generally the use of 3 series of aluminum in the welding position coated with solder and then high-temperature (600℃ or so) brazing furnace to melt the solder welding, so the process is relatively simple. Although they use the same process, there are differences in application. Stamping plate first of all, a plate stamping out the design of the flow channel, the depth of the flow channel is generally 2-3.5mm, with another plate welded together, the thickness of the two plates can be 0.8-1.5mm. The cross section of the harmonica pipe flow channel is similar to the shape of the harmonica pipe, and the two ends are fluid collection and confluence, so the internal flow direction can only be straight forward, and can not be designed at will like the stamping plate, and there are certain limitations.

However, at that time, the stamping board was not large, the battery pack needed 6-8 pieces of pure electricity, plus SAE quick plug joints and tubes, plus support foam and thermal pads, a set of costs thousands, and the use of harmonica tube can be more than 30% cheaper, a huge cost advantage.

3. Three generations of products - liquid cooling plate integration and integration

With the energy density of a single cell reaching a certain bottleneck, the energy density of the whole PACK can only be improved by increasing the pack grouping rate, in order to insert more cells into the battery pack, the modules become bigger and bigger, and even cancel the concept of modules, and pile batteries directly onto the box, which is CTP. At the same time, the battery water cooling plate is also developing in the direction of a large board, either by choosing to integrate into the box or module, or by making a large stamping plate laid at the bottom of the box or covered on the top surface of the battery cell.

4.Battery water cooling plate processing technology - welding

Of the three types, the functional complexity of the stamped plate will be higher, because it involves the requirements of stamping and welding are very demanding. At the same time, no matter what kind of battery water-cooled plate manufacturing process is used, welding is a very important process. Nowadays, the welding process of water-cooled plate is mainly divided into three categories: electric-diffusion bonding, vacuum brazing and friction stir welding. Because vacuum brazing liquid cooled plate has flexible design structure and high welding efficiency, it is widely used in the field of electric vehicles.