The electric vehicle (EV) revolution is accelerating at an alarming rate. Global electric vehicle sales have exceeded 10 million units in 2022 (IEA data), and such a large fleet requires a reliable, high-speed charging infrastructure. Charging piles are an indispensable part of the supporting infrastructure for electric vehicles, providing charging services for electric vehicles. According to the different ways of power supply, they can be divided into AC charging piles and DC charging piles. Among them, DC fast charging piles (DCFC) can directly convert alternating current (AC) from the power grid to direct current (DC) available to the battery of an electric vehicle, allowing many modern electric vehicles to be charged from 20% to 80% in as little as 20-30 minutes.

Why do charging posts need to dissipate heat?

The fast charging capacity of DC charging piles leads to the generation of a large amount of heat. The main sources of this heat are:

Power conversion losses: Inefficiencies within semiconductors and transformers during the conversion of AC to DC and the boosting process generate a lot of heat.

High current flow: The resistance of cables, connectors and internal components leads to heat that is proportional to the square of the current (I²R loss).

Out-of-control heat is not only an inconvenience, it is a direct threat to the performance, safety and longevity of the charging post. Heat dissipation in charging piles can ensure the performance, safety and life of charging piles:

Protecting equipment: EV charging piles are a kind of high-voltage equipment with complex internal circuits, including transformers, capacitors and other key components. During the charging process, these components will generate heat due to the passage of current. If the heat is not dissipated in time, it may cause the equipment to overheat or even burn out, affecting the normal operation of the equipment.

Improve service life: Effective heat dissipation ensures that the charging pile remains stable during use, thus extending its service life. This can reduce the cost of equipment replacement for public places or companies with a large number of charging piles.

Ensure safety: If the charging pile overheats during the charging process, it may cause fire or other safety accidents. Therefore, taking effective heat dissipation measures can reduce the risk and safeguard the safety of users and equipment.

Main heat dissipation methods of charging pile

1. Forced air convection cooling (e.g., independent air ducts, optimized ventilation system): accelerating the air flow to take away the heat through the fan, widely used in low and medium power scenarios.

Principle: The internal fan actively draws in the cooler surrounding air and makes it flow through the heat sink attached to the heating element (e.g., power module), and then discharges the heated air.

Advantages: Relatively simple, cost-effective, low maintenance requirements.

Disadvantages: Limited cooling capacity for ultra-high-speed charging piles (350kW+); performance degradation at high ambient temperatures; dust/moisture inhalation, requiring a robust filtration system; may be noisy.

2. Liquid cooling heat dissipation system: absorbs heat through coolant circulation, suitable for high power (60kW and above) DC charging pile, such as liquid cooling heat dissipation technology.

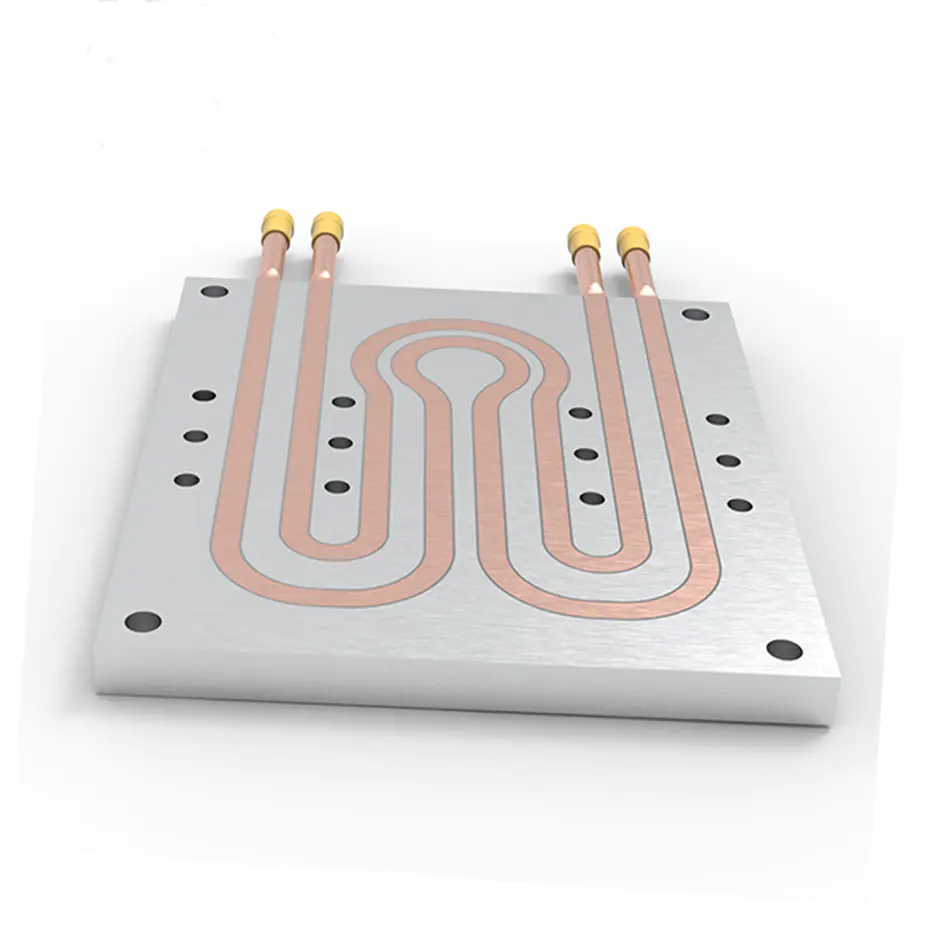

Principle: a sealed coolant circulation loop, so that the liquid (usually water-glycol mixture) flows through the liquid cold plate in direct contact with the key heat source (power electronic components). The heated coolant is pumped to a heat sink, cooled by air (sometimes with the aid of a fan) and then re-circulated.

Advantages: Outstanding heat conduction efficiency, capable of supporting higher continuous power (particularly crucial for 350kW+ charging piles). The design is more compact It runs more quietly. It offers better protection in harsh environments such as dust and moisture. It performs more stably in high-temperature environments.

Disadvantages: More complex design, higher initial cost, and possible maintenance requirements for pumps/seals.

Applicable scenarios: High-power DC fast charging piles (150kW+), ultra-fast charging piles (350kW+), and places with extreme temperatures or strict environmental requirements.

3. Natural heat dissipation and potting isolation: low power scenarios often use natural heat sinks or thermally conductive potting adhesive to improve protection performance.

Principle: Completely rely on passive heat dissipation, through carefully designed heat sinks and chassis ventilation structure, using natural air flow (hot air rise) to dissipate heat. Potting is a way of dissipating heat by filling the tiny gaps between the heat dissipating components and the heat dissipating surfaces with a thermally conductive adhesive to improve the efficiency of heat conduction.

Advantages: Simplest design, completely silent, very low maintenance requirements, high reliability.

Disadvantages: Very limited cooling capacity. Only suitable for low power applications (e.g. Level 1/2 AC charging posts).

Scenarios: Basic household use and low power public AC charging stations.

As EV battery capacity increases and charging speeds push toward 350kW and beyond, effective thermal management is no longer optional - it's a foundational requirement. Although more complex, liquid cooling systems are fast becoming the gold standard for high-power DC fast charging stations (DCFC), ensuring reliability, safety, and the ability to deliver on the promise of ultra-fast charging, with continuous and stable operation, even under harsh conditions.

LORI: Reliable Charging Experience through Advanced Thermal Technology

At LORI, we understand the critical role that thermal management plays in the performance and longevity of a charging station. We carefully design thermal solutions for high power DC fast charging piles, as well as provide cooling components such as liquid cooling panels, natural heat sinks, and thermal modules and so on, optimized for their specific power levels and target application environments. Whether it's a robust forced air-cooling system designed for consistent performance or cutting-edge liquid-cooling technology for our most powerful superchargers, LORI always prioritizes thermal efficiency to ensure the highest uptime, safety and user satisfaction.

Ready to deploy a reliable, high-performance electric vehicle charging infrastructure? We're designed to meet the challenges of high temperatures. Discover LORI's future-proof, advanced charging solutions.