What is an EV Battery Pack?

An EV battery pack is the energy storage core unit of an electric vehicle, usually consisting of multiple battery modules connected in series or parallel, each containing tens to hundreds of lithium-ion battery cells (Cells). The battery pack provides stable and efficient power output for the vehicle by integrating thermal management system, battery management system (BMS) and structural protection components.

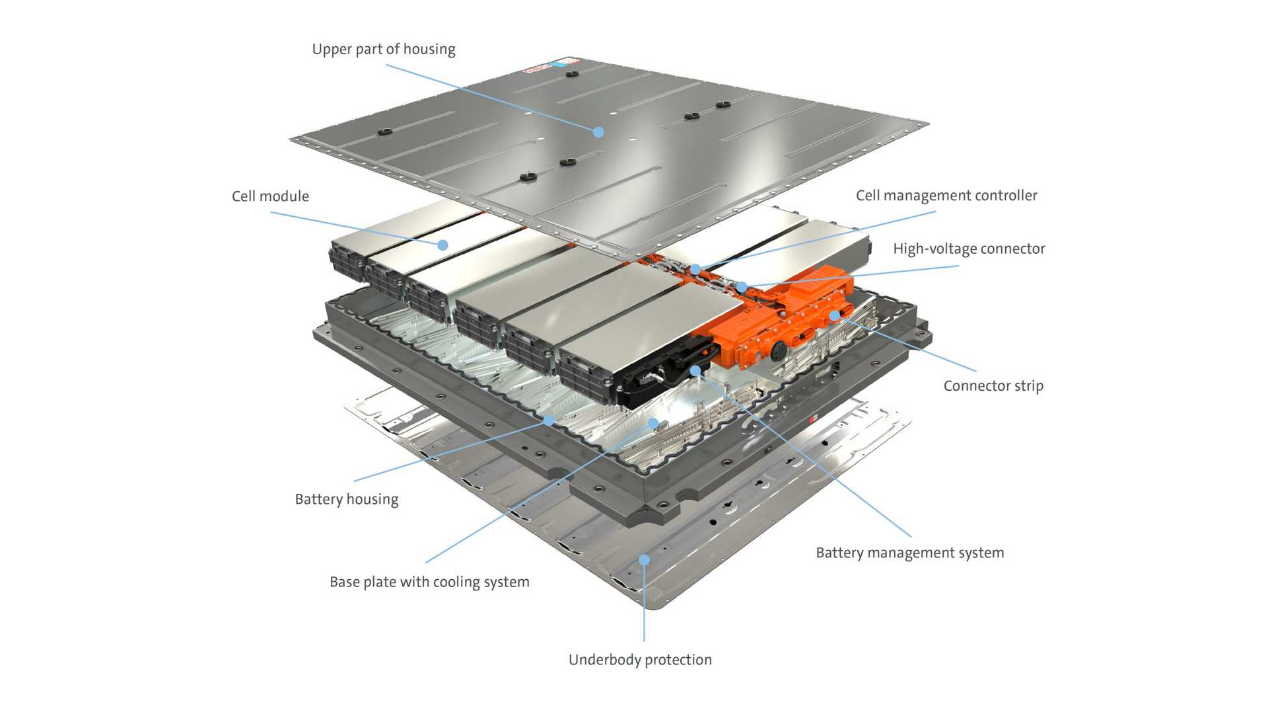

Main Components of a Power Vehicle Battery Pack

A complete battery pack usually contains the following core components:

1. Battery Cell (Cell)

Lithium-ion batteries are the mainstream choice, responsible for storing and releasing electrical energy.

2. Battery Module

Multiple battery monomers are fixed and encapsulated through series and parallel connection to form a standardized unit.

3. Thermal Management System

Liquid Cold Plate: Controls the temperature by circulating coolant (more on this later).

Thermal Conductive Adhesive/Spacer: Fill the gap between the battery and the cold plate to improve the heat conduction efficiency.

4. Battery Management System (BMS)

Monitors voltage, temperature, and state of charge (SOC) to ensure safe and balanced charging and discharging.

5. Structural Frame and Housing

Made of aluminum alloy or high-strength plastic to provide mechanical support and protection against impact, vibration and external environmental erosion.

6. Electrical Connection Components

High-voltage wiring harnesses, connectors, safety devices, etc., to ensure stable current transmission.

7. Safety Components

Pressure relief valve, fireproof isolation layer, etc., to prevent the spread of thermal runaway.

What Is Electric Vehicle Battery Liquid Cooling Plate?

EV battery cell liquid cold plate is a heat-conducting component integrated in the thermal management system of the battery pack to regulate the battery temperature. It works by circulating a coolant (typically a water-glycol mixture) through internal runners to absorb the heat generated during battery operation or charging. By maintaining the battery temperature in an optimal range (typically 20°C-40°C), liquid-cooled plates prevent overheating, thermal runaway and performance degradation.

Battery cell liquid cold plate technology is critical for modern electric vehicles, as lithium-ion batteries are highly sensitive to temperature extremes. Without efficient cooling, batteries can face shortened lifetimes, safety hazards and even catastrophic failures.

Why Are Battery Liquid Cooling Plates So Important?

Enhance Security

Overheating can cause thermal runaway (a chain reaction leading to fire or explosion). A well-designed liquid cooled battery plate dissipates heat quickly and significantly reduces this risk.

Extends Battery Life

High temperatures accelerate battery aging. Effective cooling ensures that the battery operates reliably and maintains its capacity over thousands of charge/discharge cycles.

Optimize Performance

Batteries operate efficiently only within a narrow temperature range. Continuous cooling supports fast charging, high power output and longer range.

Space and Lightweight Advantages

Liquid-cooled plates provide better heat dissipation in a more compact structure than air-cooling, making them suitable for high-density layouts of battery modules.

Main Types of Liquid-cooled Plates for Electric Vehicle Batteries

According to thermal management requirements, space constraints and cost considerations, liquid cooling panel designs are categorized into the following types:

1. Harmonica tube type liquid cooling plates

Advantages: low cost, light weight, relatively simple structure, high production efficiency.

Limitations: single flow path, small contact area, thin pipe wall, general heat transfer effect, poor load-bearing capacity.

2. Stamping type liquid cooling plate

Advantages: arbitrary design of runner, large contact area, good heat transfer effect, high production efficiency, good pressure resistance and strength.

Limitations: need to open the mold, high cost, and high flatness requirements, installation difficulties.

3. Aluminum blowing liquid cooling plate

Advantage: low cost, good heat exchange, high production efficiency.

Limitations: The material is soft, so it is weak in terms of pressure resistance and strength.

4. Snake tube liquid cold plate

Advantage: Good heat transfer, suitable for cylindrical cells.

Limitation: Complex structure and high cost.

5. Friction stir welding liquid cooling plate

Advantages: good reliability, good load bearing capacity, good surface flatness, good heat exchange effect.

Limitations: complex processing, high cost, thicker and heavier and high space occupation.

How to Choose the Right Liquid Cooling Plate for Your Battery?

The following factors need to be considered when choosing a liquid cooling plate:

Thermal load: High-performance cells may require a snake tube or microchannel design.

Space constraints: stamping cold plates are suitable for compact modules.

Cost: snake tube cold plates and stamping cold plates are more economical.

Durability: Aluminum alloys are popular for their light weight and corrosion resistance.

As electric vehicles become more popular, battery liquid cooling panel design will continue to be critical. At Lori, we are committed to providing cutting-edge solutions, focusing on customized electric vehicle battery cooling systems that balance thermal efficiency, weight, and cost to ensure that your battery packs operate safely and efficiently and meet the escalating demands of the automotive industry.Contact the Lori team to customize a personalized cooling solution for your next project!