What is server memory? Why do You need to cool it?

In data centers and cloud computing infrastructures, server memory is the core hardware that carries high-speed access to data. Unlike ordinary desktop memory, server memory (e.g., DDR4/DDR5 RDIMM/LRDIMM) features higher capacity (up to 256GB in a single strip), stronger error correction (ECC technology), and multi-channel design to meet the demands of high-load scenarios such as AI training and big data analysis.

However, the densification of memory modules is causing a heat dissipation crisis:

The power of a single DDR5 memory can reach 15-20W, and even some single rack memory power densities have exceeded 30W/DIMM

Failure rate incre ases by 30% for every 10°C increase in memory temperature (based on reliability data)

Traditional air-cooled cooling efficiency drops by 50% at 40°C ambient temperature.

When the memory temperature exceeds 85°C, the system triggers underclocking protection, resulting in a precipitous drop in computing performance. Efficient heat dissipation has become a key battleground for ensuring server stability and energy efficiency ratio.

Lori Server Memory Liquid Cooling Customized Design

1.DIMM Cold Plate: Micro-channel design for precise temperature control

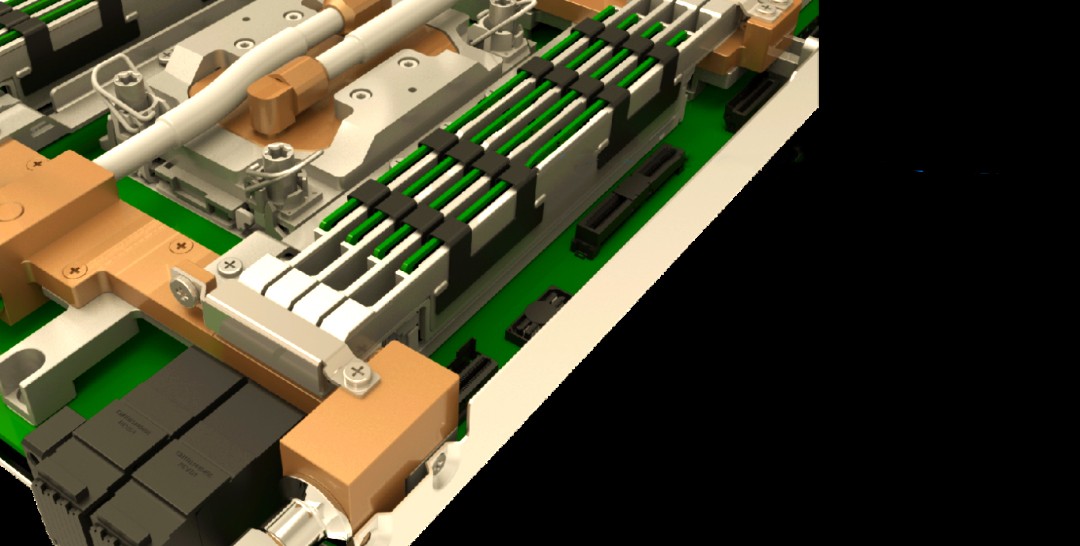

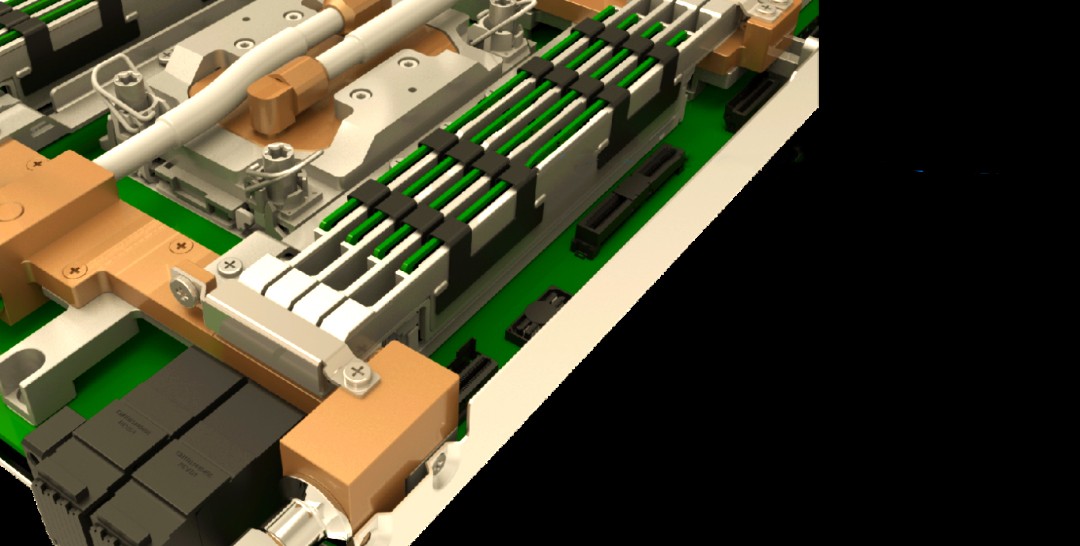

Lori's customized liquid cooling solution for memory modules adopts a fully wrapped aluminum/copper alloy cold plate/stainless steel cold plate, which directly touches the memory module chips through precision machined microchannels.Lori's customized DIMM Cold Plate supports different DIMM pitches (DDR4 and DDR5), which is suitable for a wide range of server architectures, and eliminates the need to replace the entire cooling system due to hardware upgrades.

2.Server Memory Module Custom Liquid Cooling Loop

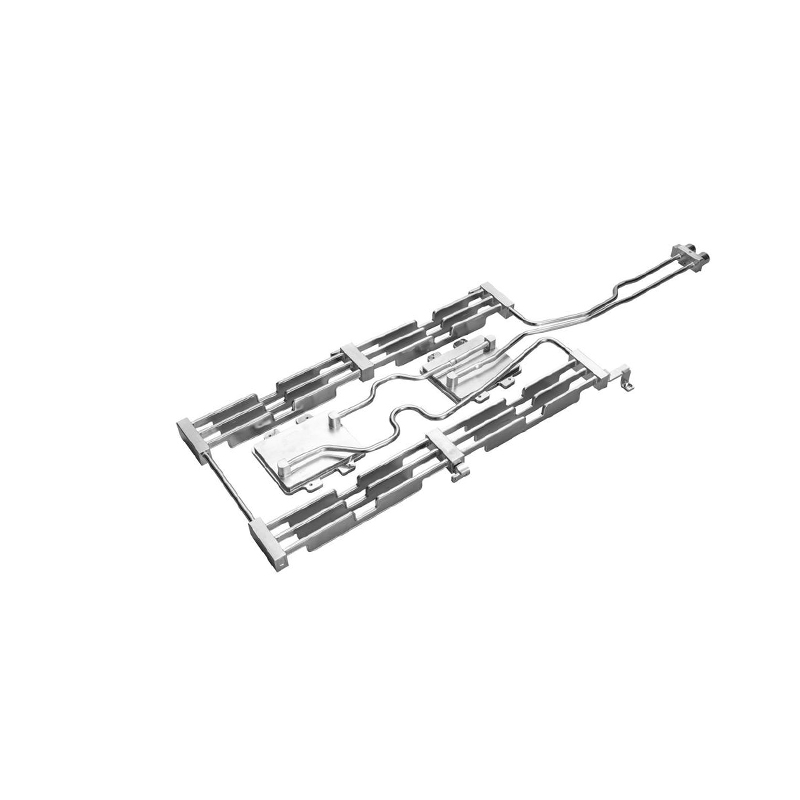

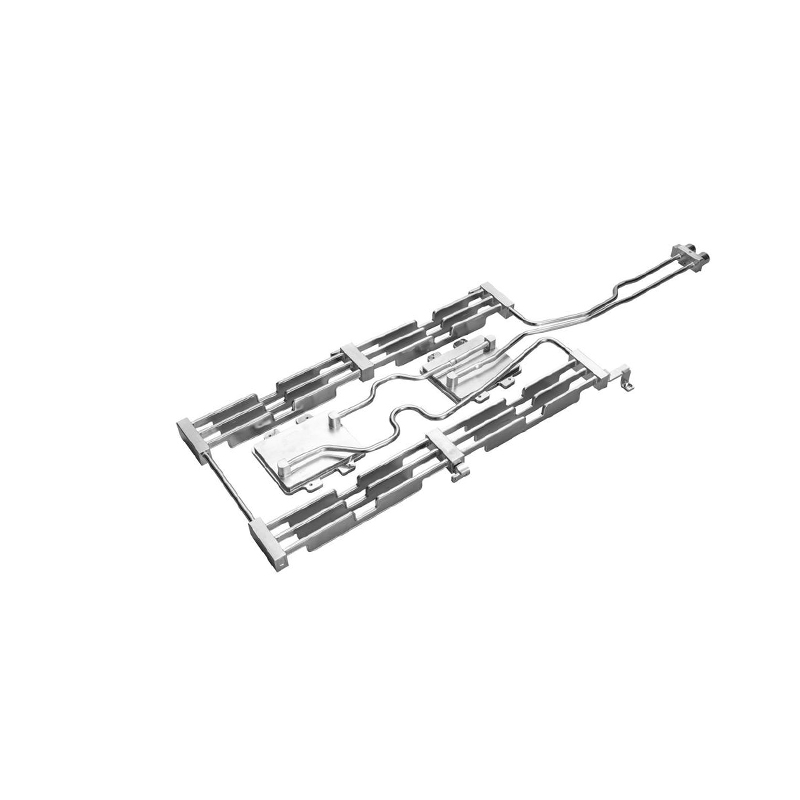

Lori can provide direct liquid cooling open loops for CPU, GPU, DIMM and other chips according to the customer's server liquid cooling deployment requirements. The customized memory and CPU modular liquid cooling loops are formed by welding metal pipes and CPU cold plates and memory module cold plates through the vacuum brazing process, which ensures that there is no leakage of the liquid cooling system of liquid-cooled servers and the equipment is safe and stable to operate while efficiently dissipating heat.

Server Memory and CPU Module Liquid Cooling Loop

Core Advantages of Memory Liquid Cooling Technology

1. Precise temperature control and thermal resistance optimization

DIMM Cold Plate is in direct contact with the memory chips through the micro-flow channel design, and the liquid cooling of the cold plate can reduce the thermal resistance to less than 0.03°C/W. The strong heat dissipation capability of a single module ensures that the temperature of the memory is stabilized at a safe threshold value. Combined with the intelligent temperature control system, the coolant flow can be adjusted in real time according to the memory load to avoid the formation of localized hotspots.

2. Energy efficiency improvement and PUE optimization

Liquid-cooled memory module can reduce the energy consumption of heat dissipation to 1/10 of that of air-cooling, for example, for a traditional air-cooled system that consumes 500kW of power to dissipate heat, liquid cooling only requires 30kW, which is a significant energy saving benefit. The liquid cooling solution for memory modular cold plate reduces the overall PUE value of the data center to less than 1.2.

3. Space utilization and deployment flexibility

The liquid cooling design eliminates the need to reserve space for air ducts and supports high-density stacking of memory modules (e.g., integrating more DIMM slots in a 1U server) to increase the computing power density of a single rack. The modular memory liquid cooling design is compatible with existing server architectures, making it easy to retrofit existing data centers and reducing upgrade costs.

Key application scenarios for liquid memory cooling

AI Training and Reasoning

AI model training requires frequent reading and writing of large-scale datasets, which increases the demand for memory bandwidth and capacity. Liquid-cooled memory can avoid computation interruptions due to insufficient heat dissipation. For example, after a supercomputing center adopted cold plate liquid cooling, the memory error rate of AI clusters dropped by 92%.

High Performance Computing (HPC)

In scenarios such as weather simulation and gene sequencing, continuous high-load operation requires high memory stability. The liquid cooling solution extends hardware life and reduces maintenance frequency through precise temperature control.

Edge Computing and Compact Data Centers

Edge devices are limited by space and power supply, and the compact design of liquid-cooled memory (e.g., integrated cold plate loop) supports high-density deployment while reducing noise pollution, making it suitable for real-time demanding scenarios such as medical image processing and autonomous driving.

With the exponential growth of arithmetic demand, server memory liquid cooling solutions have become the core technology for liquid-cooled servers to break through the arithmetic bottleneck and transform green data centers. Lori provides cutting-edge thermal management technologies and innovative solutions for the global computing infrastructure through innovative designs ,DIMM cold plates, memory and CPU modular liquid cooling loops and so on.

Server Memory and CPU Module Liquid Cooling Loop

Server Memory and CPU Module Liquid Cooling Loop