Aluminum heat sinks are critical components used in various products for consumer electronics, equipment, and systems, playing a crucial role in dissipating heat from sensitive components. As electronic devices become more compact and powerful, efficient heat sink design and manufacturing methods are increasingly emphasized. With the continuous global demand for aluminum heat sinks on the rise, manufacturers are constantly seeking methods to improve production process efficiency.

This article will discuss two main manufacturing methods for aluminum heat sinks: CNC machining and aluminum extrusion. We will also explore the advantages of each method and compare their relative efficiencies.

Overview of CNC Machining and Aluminum Extrusion Processes

CNC Machining

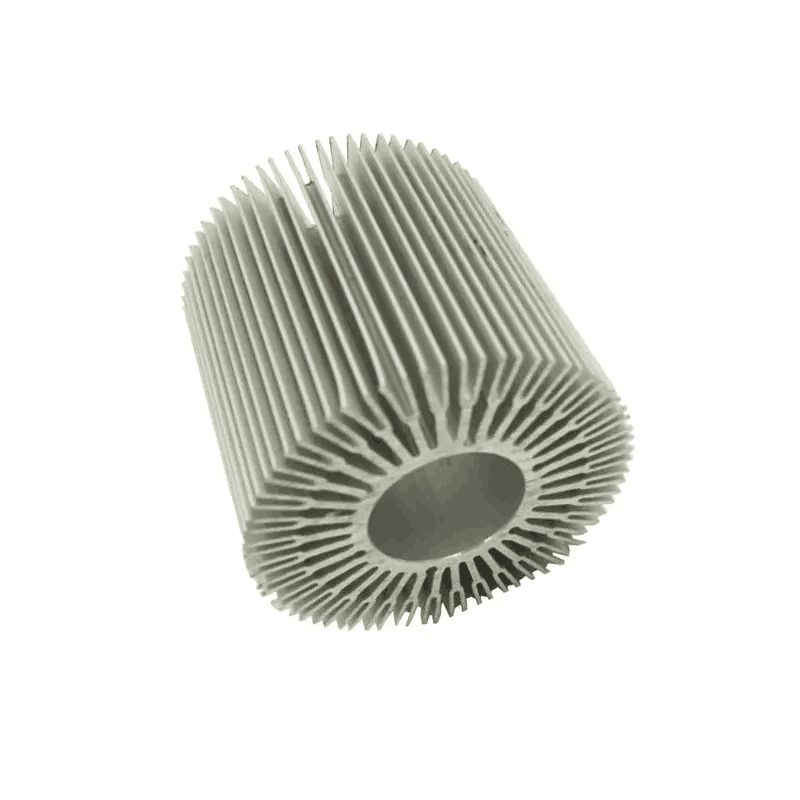

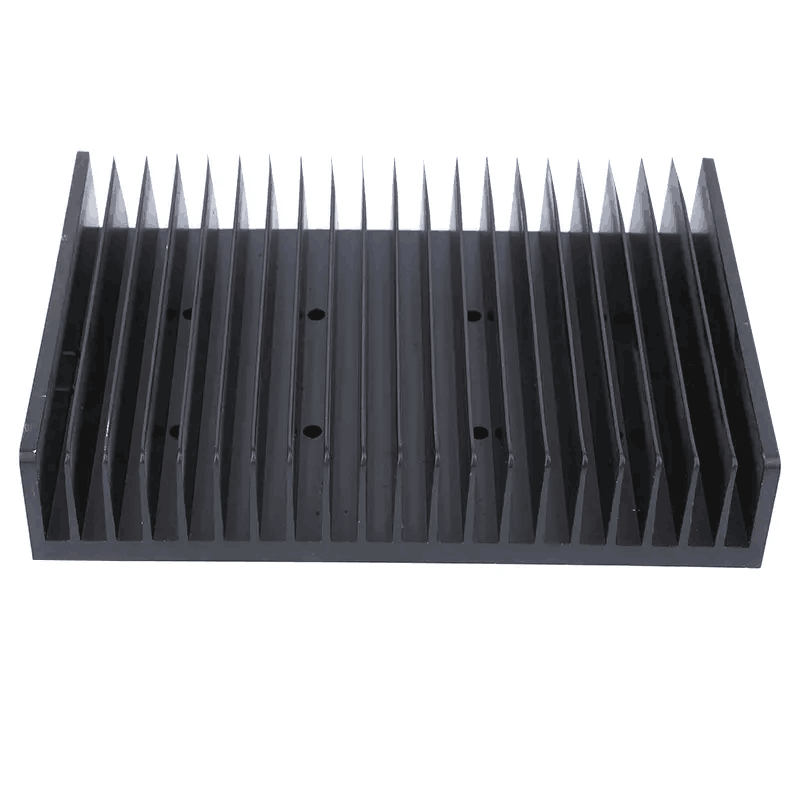

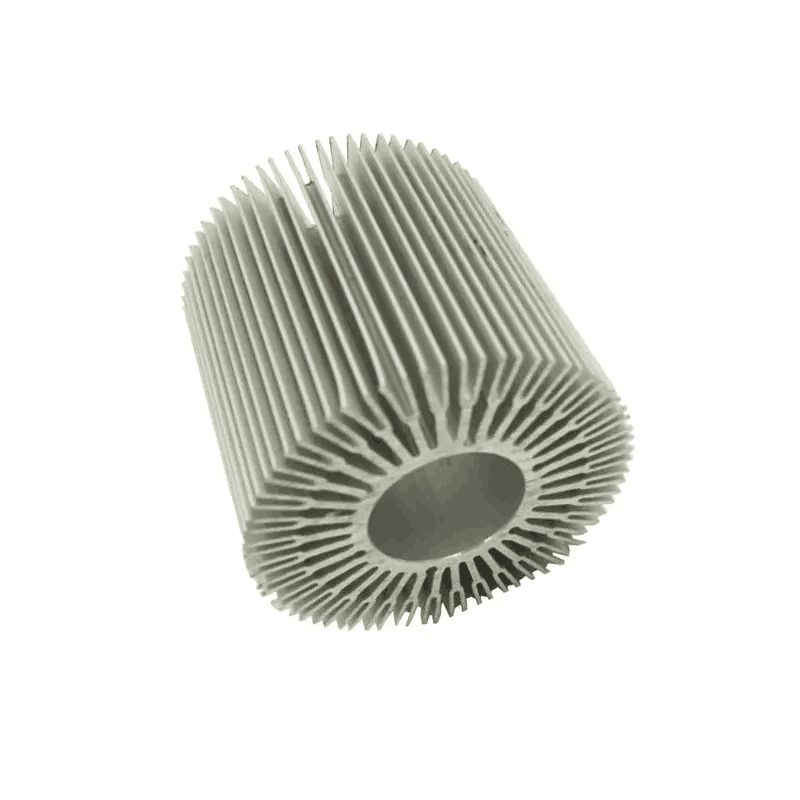

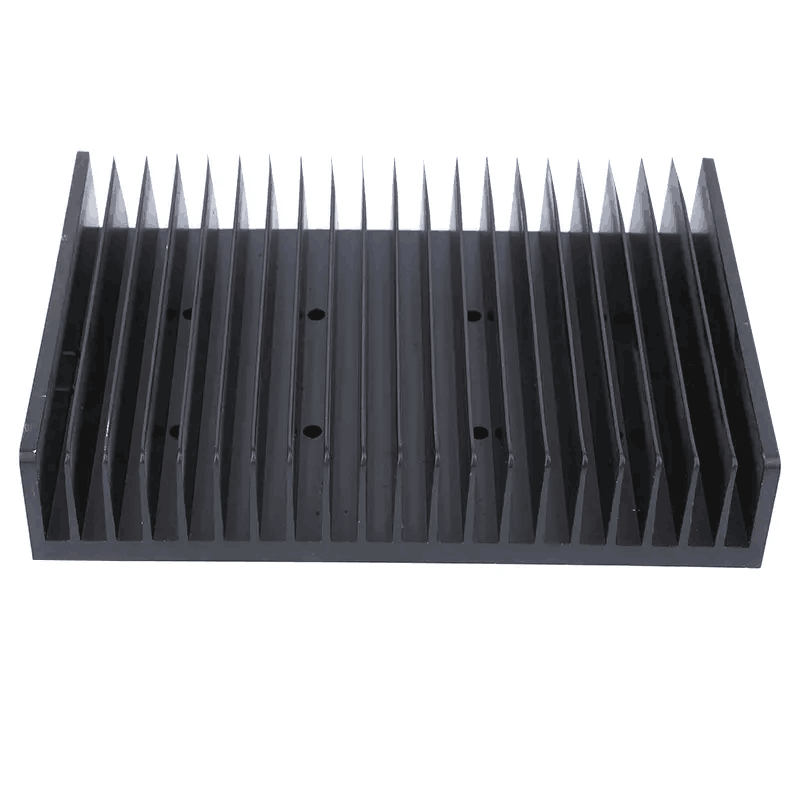

CNC (Computer Numerical Control) machining is a process where material is removed from a workpiece using computer-controlled machines to shape it into the desired form. In aluminum heat sink manufacturing, CNC machines cut and shape raw aluminum material through milling or turning operations into the final heat sink design. This process allows for the creation of highly complex and precise heat sink geometries tailored to specific thermal management requirements.

Aluminum Extrusion

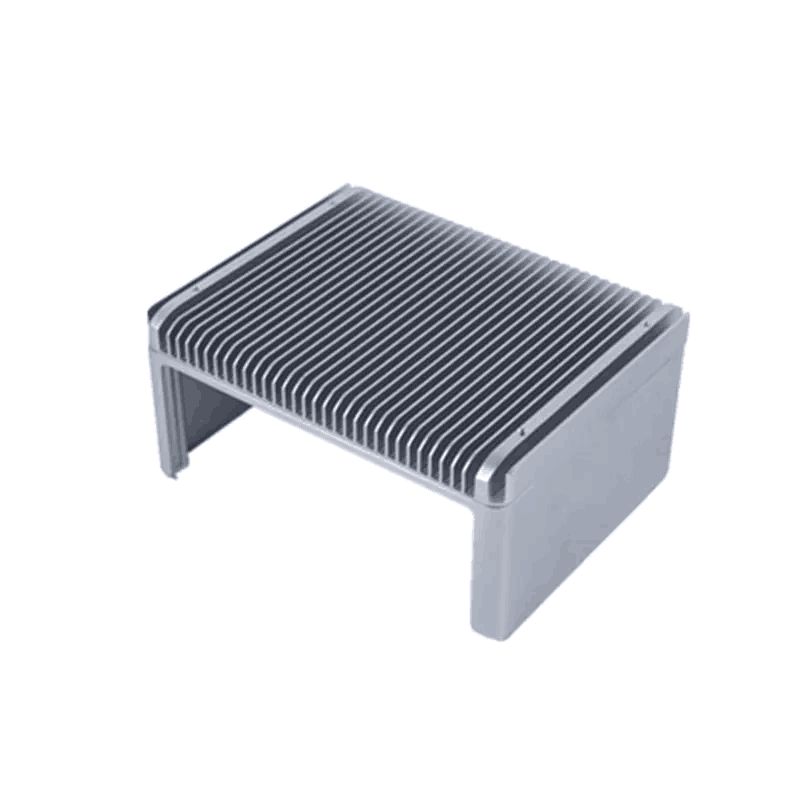

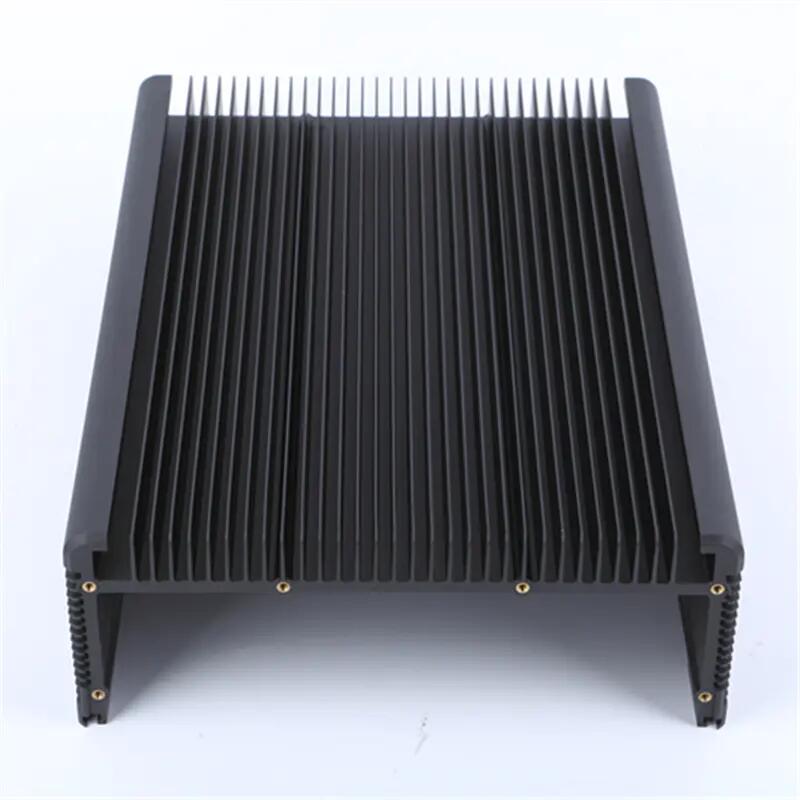

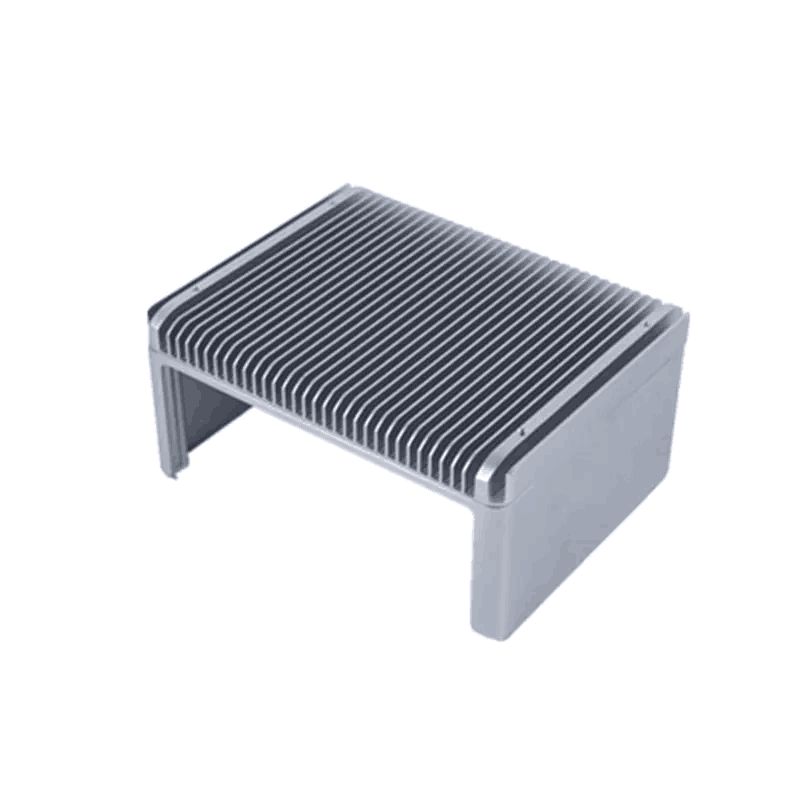

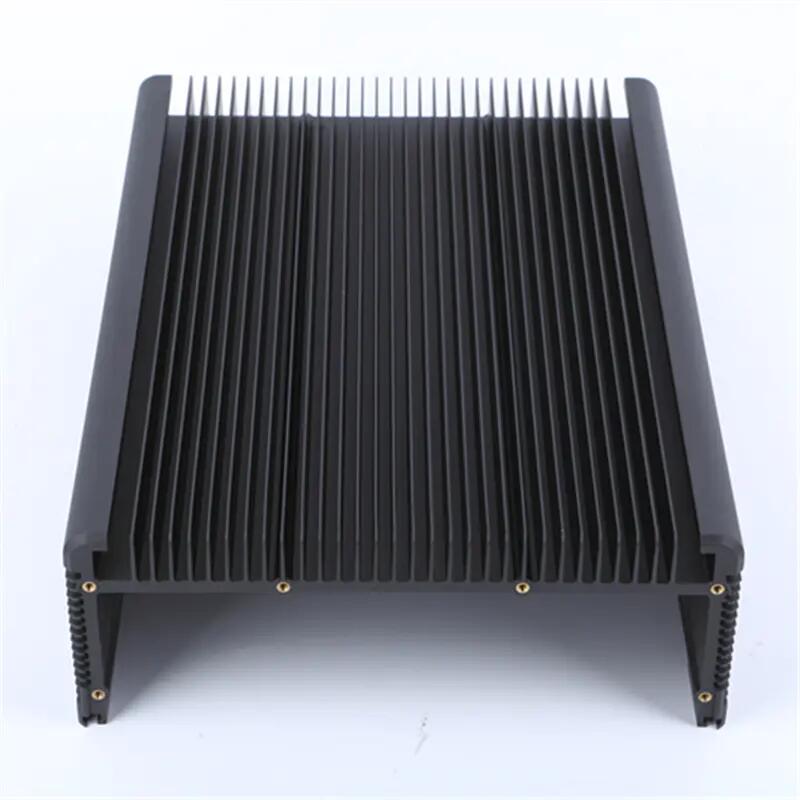

Aluminum extrusion is another widely used method for heat sink manufacturing. In this process, heated aluminum billets are forced through a mold to produce long aluminum profiles with the desired cross-sectional shape. These extruded profiles are then cut into smaller pieces, which may undergo further processing as needed to produce the final heat sink. Extrusion is an efficient and economical method for producing aluminum heat sinks, especially in large-scale production.

Advantages of CNC Machining heat sinks

CNC machining offers several advantages in aluminum heat sink production:

Precision: CNC machining aluminum allows for the creation of high-precision heat sink designs with tight tolerances and complex geometries, ensuring optimal thermal performance for specific applications.

Material Versatility: CNC machining can handle various grades of aluminum alloys, each with unique properties and characteristics. This flexibility allows manufacturers to choose the best heat sink material based on factors such as thermal conductivity, corrosion resistance, and weight.

Reduced Lead Times: Compared to some other manufacturing methods, the CNC machining process can produce aluminum heat sinks relatively quickly, helping to shorten lead times and improve overall production efficiency.

Customization: CNC machining enables highly customized heat sink designs, allowing manufacturers to produce tailored solutions for customers. This is particularly advantageous for niche applications or specialized industries where off-the-shelf solutions may not meet specific requirements.

Advantages of Aluminum Extrusion heat sinks

Aluminum extrusion also provides several key advantages for heat sink manufacturing:

High Production Efficiency: Extrusion is inherently an efficient manufacturing process as it produces continuous aluminum profiles with minimal waste. This can save costs, especially for large-scale production.

Design Flexibility: While not as versatile in terms of design complexity as CNC machining, aluminum extrusion still allows for a variety of heat sink shapes and sizes. This is beneficial for manufacturers seeking to balance design flexibility with production efficiency.

Stable Quality: Aluminum heat sinks produced through extrusion have consistent quality and uniform material properties. This helps ensure reliable heat dissipation throughout their operational lifespan.

Scalability: Aluminum extrusion profiles are highly scalable, making them an ideal choice for manufacturers needing to produce large quantities of heat sinks. The extrusion process can easily scale up or down to meet different production needs without significant impacts on cost or lead times.

Comparing Efficiency of CNC Machining and Aluminum Extrusion heat sinks

In terms of manufacturing efficiency, CNC machining and aluminum extrusion each have their pros and cons. CNC machining can produce highly complex and customized heat sinks, but the process may be more time-consuming and costlier, especially for large-scale production. On the other hand, aluminum extrusion is a more cost-effective method for producing large quantities of heat sinks efficiently, although it may not be suitable for complex or specialized designs.

Ultimately, the choice between CNC machining and aluminum extrusion for heat sink manufacturing depends on factors such as design complexity, production volume, and material characteristics.

Factors to Consider When Choosing a Heat Sink Manufacturing Method

When selecting a method for manufacturing aluminum heat sinks, several factors should be considered:

Design Complexity: CNC machining is preferred for heat sinks with complex geometries or strict tolerance requirements due to its higher precision and accuracy compared to extrusion. However, for simpler designs, aluminum extrusion may be a more efficient and cost-effective choice.

Production Volume: For large-scale production, aluminum extrusion is typically more efficient and cost-effective. However, for small batches or one-off projects, CNC machining may be more suitable.

Material Characteristics: The choice of manufacturing method may be influenced by the specific aluminum alloy used for the heat sink. Depending on factors such as machinability, thermal conductivity, and corrosion resistance, certain alloys may be better suited to one method over another.

Lead Times: Generally, CNC machining can produce aluminum heat sinks more quickly, especially for small-scale production or custom designs. However, for large-volume production, extrusion processes may offer shorter overall lead times.

Budget: Consider the costs associated with each manufacturing method, including setup costs, material costs, and production time. Although CNC machining may be more expensive for large-scale production, it could be a more cost-effective choice for small batches or highly specialized designs.

Customer Case Studies

Case Study 1: Aluminum Extrusion heat sinks for LED Lighting

In this case study, a LED lighting system manufacturer needed high-performance aluminum heat sinks for their new product line. The heat sinks required a relatively simple design with a large surface area for efficient heat dissipation. After considering various options, the manufacturer decided to use aluminum extrusion to produce the heat sinks. The extruded aluminum profiles were cut to the required lengths and processed into the final heat sink design. The finished extruded aluminum heat sinks demonstrated excellent thermal performance due to their large surface area and efficient airflow design. The extrusion process enabled cost-effective production, making it an ideal choice for this specific application.

Case Study 2: CNC Machining Aluminum heat sinks for Aerospace Applications

In this case study, an aerospace component manufacturer needed highly customized aluminum heat sinks for critical components in their product line. These heat sinks required complex geometries, strict tolerances, and specific thermal management requirements. After evaluating various options, the manufacturer chose to use CNC machining to produce the heat sinks. CNC machining allowed the use of specialized aluminum alloys with excellent thermal performance to create the required high-precision and complex geometries. The finished heat sinks exhibited outstanding thermal performance, meeting stringent requirements for aerospace applications. Although CNC machining costs more than extrusion, the custom design and specialized material properties made it the ideal choice for this specific application.

Lorimachining Heat Sink Manufacturing

At Lorimachining, we understand the importance of efficient heat sink design and manufacturing methods, especially with the increasing demand for aluminum heat sinks. We continuously seek to improve production process efficiency and offer innovative solutions to meet customer needs. Our CNC machining capabilities enable us to create highly complex heat sink geometries and customize them according to specific thermal management requirements. We provide highly customized heat sink designs, allowing us to offer tailored solutions to customers. This is particularly beneficial for niche applications or specialized industries where off-the-shelf solutions may not be suitable. We also specialize in aluminum extrusion, which is an efficient and cost-effective method, especially for large-scale production of aluminum heat sinks. Our extrusion process produces aluminum heat sinks with stable quality and consistent material properties, ensuring reliable operation throughout their lifespan. At Lorimachining, we are committed to meeting customer-specific requirements and ensuring they receive the highest quality products and services. We pride ourselves on competitive pricing and shorter lead times, achieved through innovative solutions and efficient production processes.

Conclusion

In aluminum heat sink manufacturing, two main methods should be considered: CNC machining and aluminum extrusion. Each method has its pros and cons, and the choice depends on factors such as design complexity, production volume, and material characteristics. Ultimately, the goal of any heat sink manufacturing process is to produce high-performance, efficient, and reliable solutions that meet specific application requirements. With continued focus on energy efficiency and rapid technological advancements, the aluminum heat sink industry is poised for continuous growth and innovation. Contact us now to learn more about our aluminum machining services and how we can help meet your aluminum heat sink needs. Our expert team is ready to answer any questions or concerns you may have and provide the best solutions for your specific application.

Frequently Asked Questions

1. What are aluminum heat sinks?

Aluminum heat sinks are components used in electronic devices and systems for dissipating heat from sensitive components. Due to their high thermal conductivity and cost-effectiveness, heat sinks are typically made from aluminum.

2. What is CNC machining?

CNC machining is a process where material is removed from a workpiece using computer-controlled machines to shape it into the desired form. In aluminum heat sink manufacturing, CNC machines typically use milling or turning operations to cut raw aluminum material and shape it into the final heat sink design.

3. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process involving forcing heated aluminum billets through molds to produce long aluminum profiles with the desired cross-sectional shape. These extruded profiles are then cut into smaller pieces and may undergo further processing to produce the final heat sink.

4. Which is better for aluminum heat sink manufacturing, CNC machining or aluminum extrusion?

The choice between CNC machining and aluminum extrusion for manufacturing aluminum heat sinks depends on factors such as design complexity, production volume, and material characteristics. CNC machining is suitable for producing heat sinks with complex geometries or strict tolerance requirements, whereas aluminum extrusion is more suitable for large-scale production and simpler designs.

5. What are the trends in the aluminum heat sink industry?

Trends in the aluminum heat sink industry include a focus on energy efficiency, integration of advanced technologies, customization, and material innovation. These trends drive innovation in heat sink design and manufacturing processes, as well as the development of new materials.