In the context of modern electronic devices increasingly pursuing high performance and compact design, heat dissipation has become one of the key factors restricting their development. As an innovative heat dissipation solution, the skived fin heat sink plays a significant role in the field of high-power electronics cooling with its unique structural design and efficient heat dissipation capabilities.

Material Selection for skived fin Heat Sink

The material selection of the skived fin heat sink directly impacts its heat dissipation effectiveness and cost. When extreme heat dissipation performance is required, copper (CU) with its high thermal conductivity coefficient of 380W/m.k becomes the preferred material. However, its high cost limits its widespread application. Therefore, aluminum has emerged as a more economical and practical choice. Commonly used aluminum materials include AL1050 and AL1060, both with a thermal conductivity coefficient of 210W/m.k. Not only do they possess excellent thermal conductivity, but their softness also makes them easy to process, making them particularly suitable for manufacturing skived finheat sinks. In cases where the fin height is relatively low, AL6063 (thermal conductivity coefficient of 201W/m.k) is also a viable option. Although it has a higher hardness, it can still demonstrate good heat dissipation performance in specific scenarios.

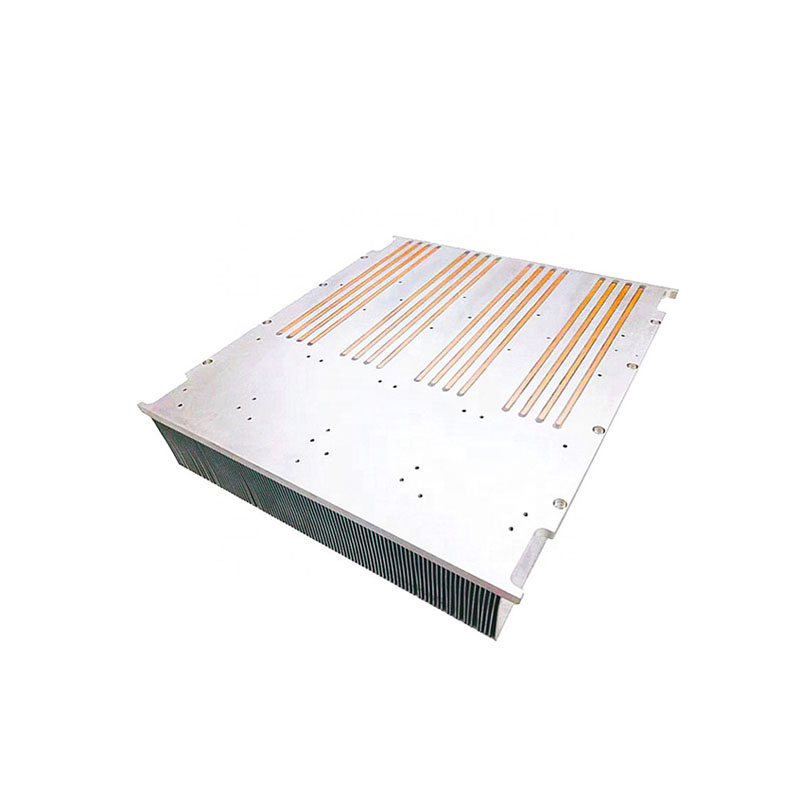

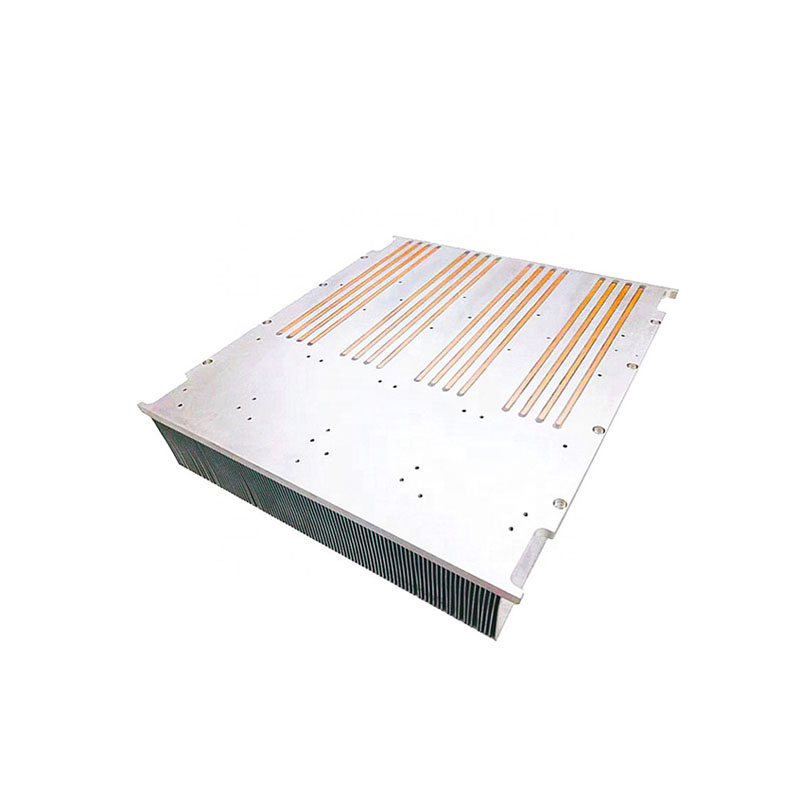

Process and Characteristics of skived fin Heat Sink

The skived fin heat sink utilizes precise mechanical movements to cut materials into blocks and straight lines from specific angles, repeatedly forming a consistent gap structure. This design not only increases the heat dissipation area but also improves the heat dissipation efficiency by 8-15% compared to traditional pin-fin heat sinks. The core advantages of the skived fin heat sink lie in:

Integrity: The skived fin heat sink plate is made from a single piece of profile material with no joints, enabling it to fully utilize the heat dissipation properties of the profile.

Efficient Heat Dissipation: The skived fin process creates thinner and denser fins, significantly enhancing heat dissipation efficiency.

Flexibility in Size: Compared to aluminum extrusion and other processes, the skived fin process has fewer size limitations, allowing for the production of wider heat sinks suitable for high-power machines.

Material Compatibility: The skived fin process is not only suitable for aluminum but also copper products and thin fins, which is difficult to achieve with other integrated heat sinks and processes.

Wide Range of Applications

Due to its efficient heat dissipation capabilities, the skived fin heat sink is widely used in industries with high power consumption and heat dissipation requirements, such as power, medical, communications, industrial control, and servers. In these fields, the skived fin heat sink not only effectively reduces device temperatures, prolonging component lifespans, but also minimizes fan noise, enhancing user experience.

Advantages of Aluminum skived fin Heat Sink

Aluminum skived fin heat sinks typically employ pure aluminum materials combined with integrated molding technology, improving the stability of heat dissipation performance. Pure aluminum materials possess excellent thermal conductivity and light weight, helping to reduce the overall burden of the equipment. Additionally, the integrated molding design minimizes thermal resistance during heat dissipation, further enhancing efficiency.

In conclusion, the skived fin heat sink, as an innovative heat dissipation solution, is gradually becoming the preferred choice for high-power electronics cooling due to its unique process, efficient heat dissipation performance, and wide range of applications. With continuous technological advancements and further cost reductions, the application prospects of the skived fin heat sink will be even broader.