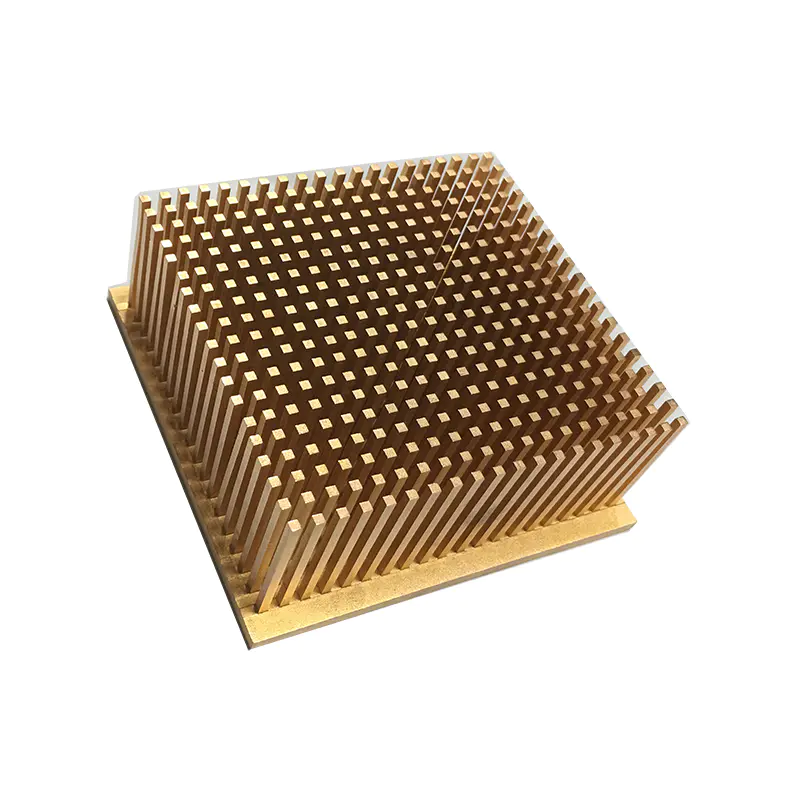

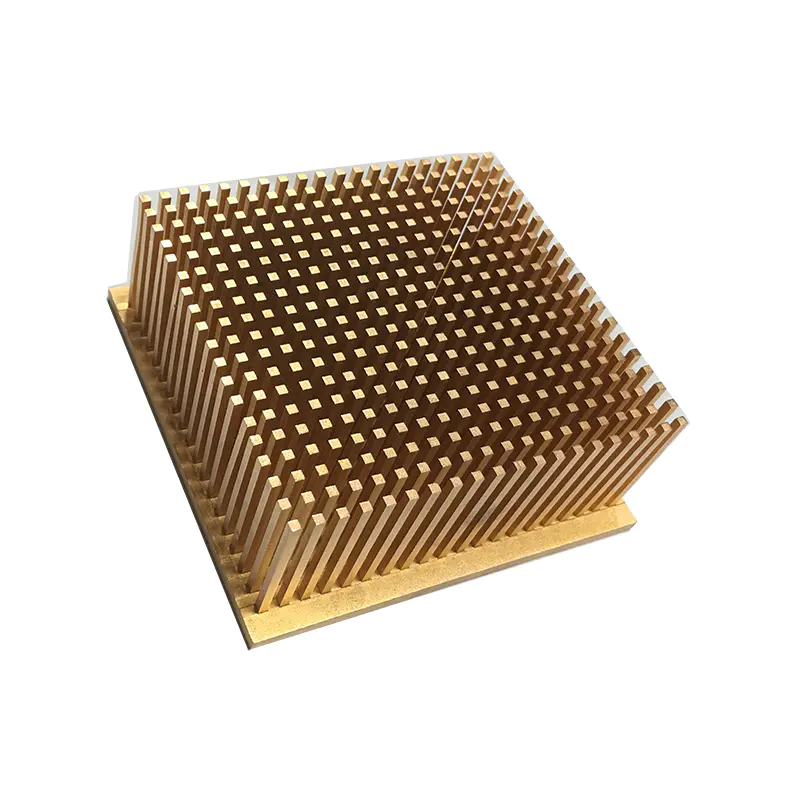

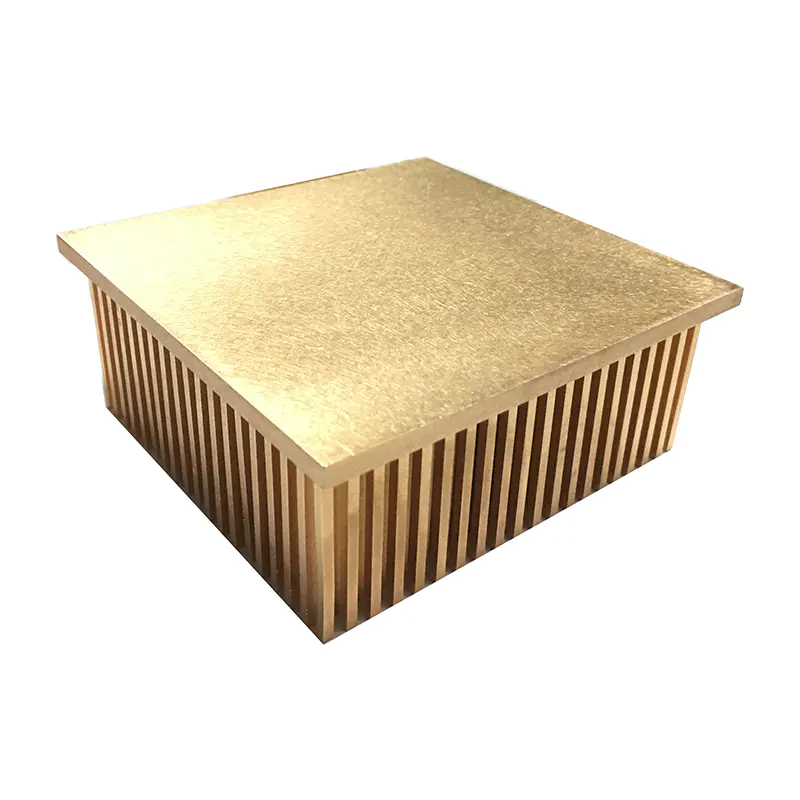

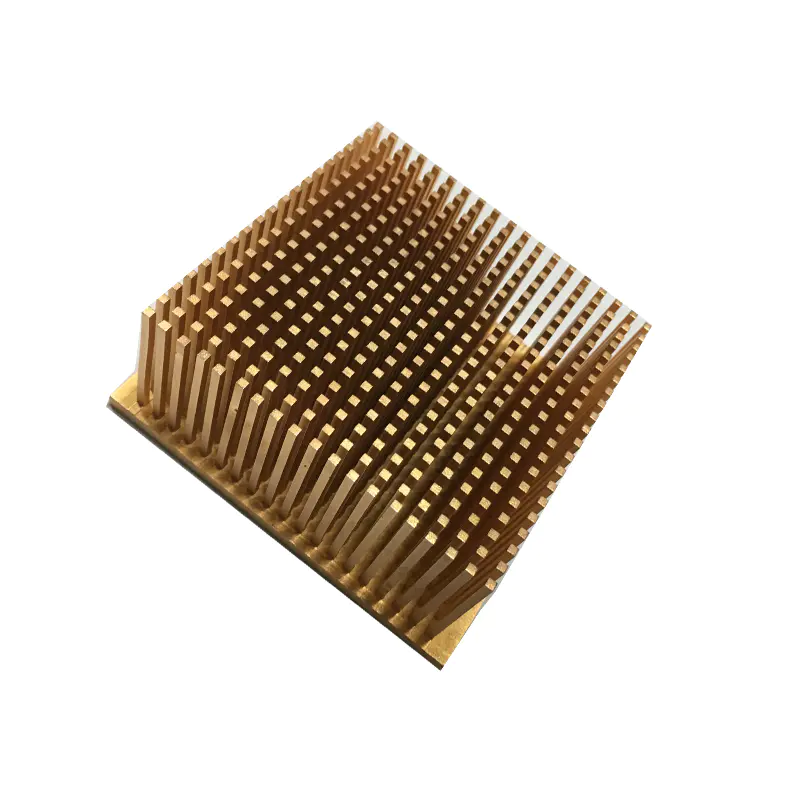

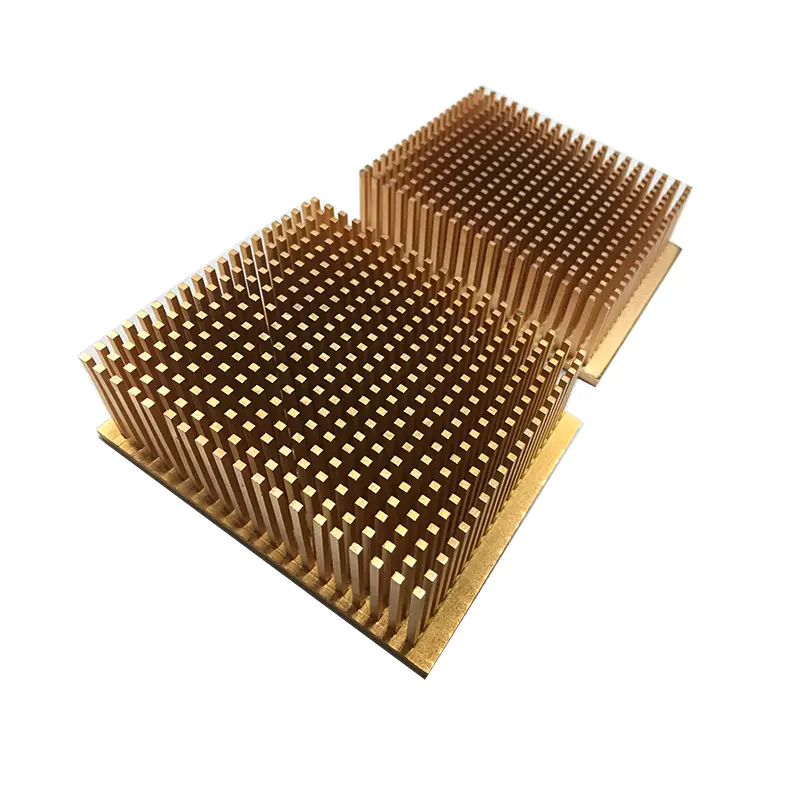

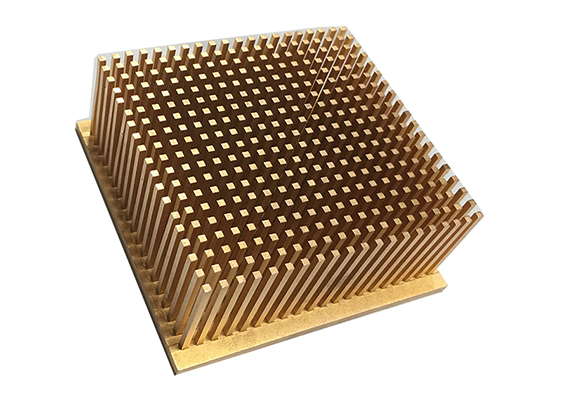

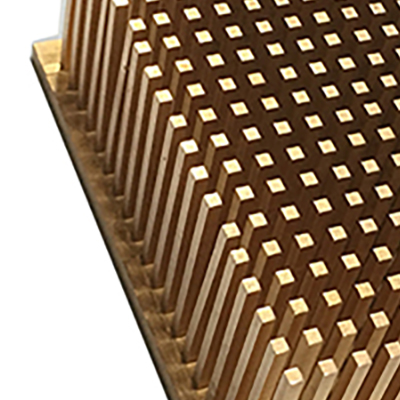

Cold forging copper pin fin heat sink

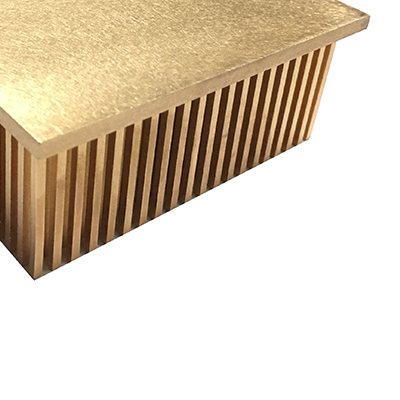

Cold forged heatsink has good mechanical properties, high productivity and high material utilization; and is particularly suitable for mass production, thus reducing the production cost.

In addition, the heat resistance of the heat sink is good, The low thermal resistance and high thermal effects. This can be assured of the transfer of heat in a satisfied stylish so as to achieve the ultimate cooling effect.

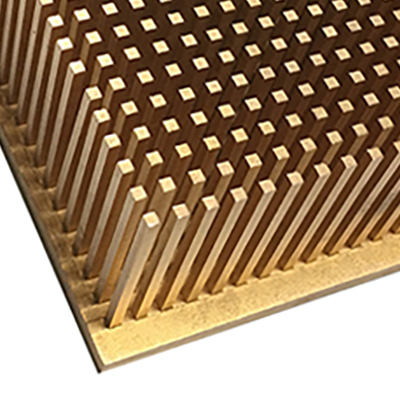

The cold forging copper pin fin heat sink adopts cold forging technology for integrated design and production, with low thermal resistance and good heat conduction effect, effectively ensuring the timely export of heat and achieving the ultimate heat dissipation effect

Cold forging heat sink has better mechanical performance, higher throughput and higher material utilization rate and cost saving

All aluminum heatsink fin and heat absorption bottom integrated formation, no interface impedance; Slender to tall, up to 50; Suitable for processing cylindrical fins.

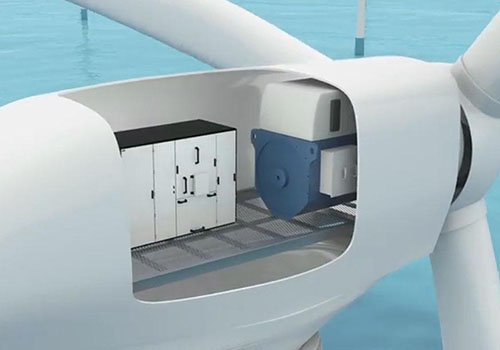

Applications to light source heat sinks and LED heat sinks, high-voltage inverters, wind power converters, and electric motor controllers.