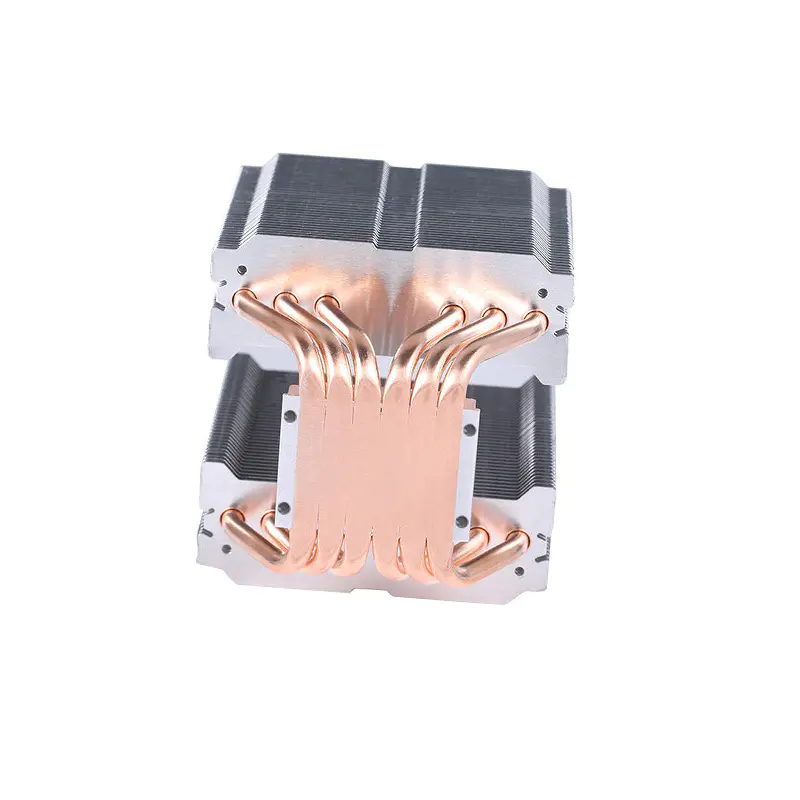

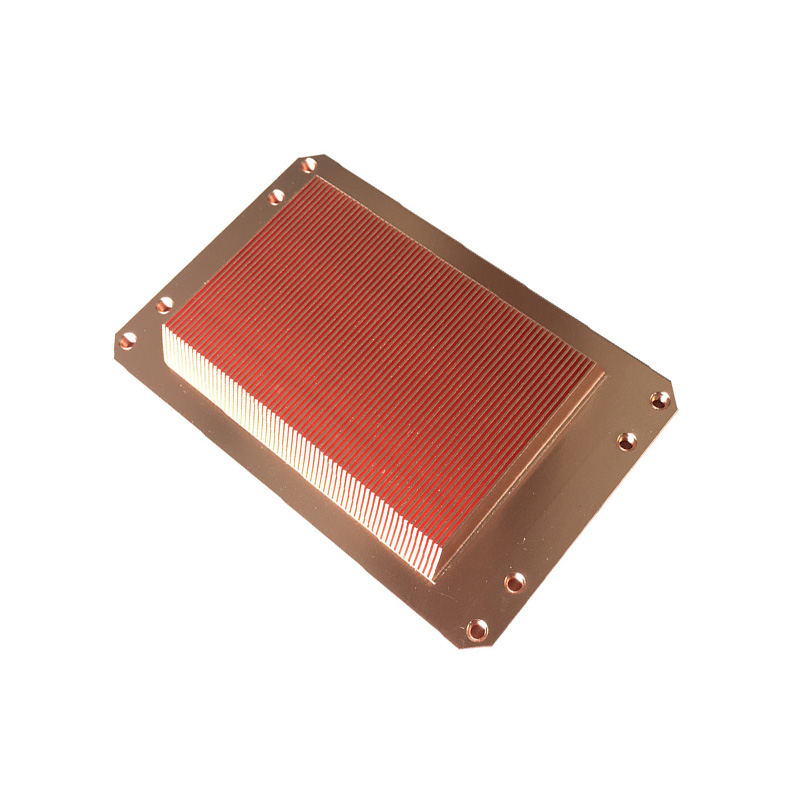

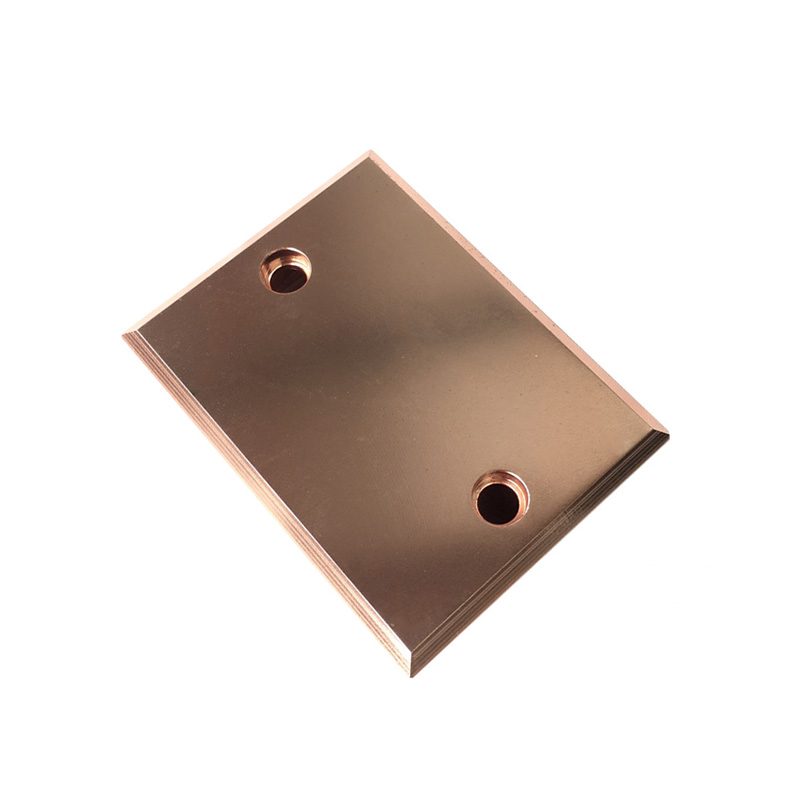

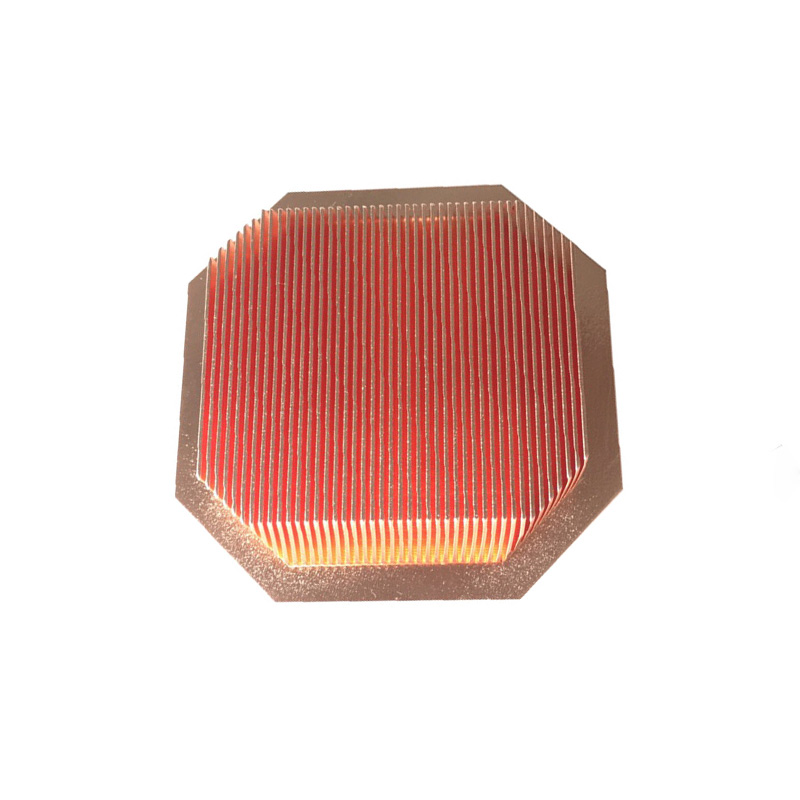

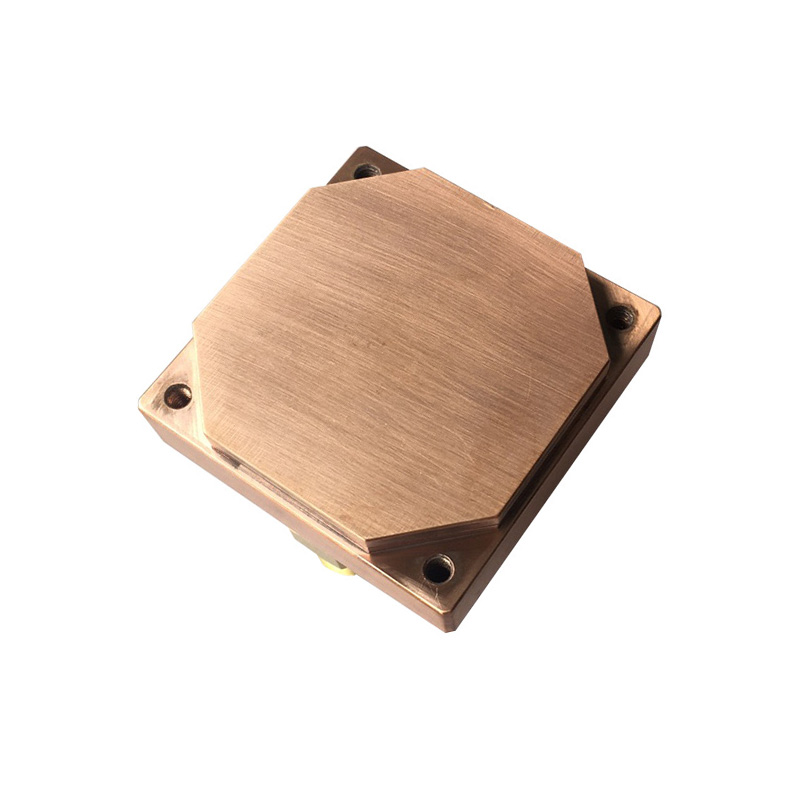

Custom CPU and GPU Vacuum Brazing Skived Fins Liquid Cooling Heat Sink for Server

With the development of CPU and GPU chips from Intel, AMD, NVIDIA and other companies, the heat dissipation requirements of PCS, servers, workstations and other devices are increasing.This custom copper skived fin liquid cooling heat sink increases heat dissipation by skived fins providing microchannels for the flow of the coolant.The copper micro-channel cold plate heat sink has been fully tested and validated by Lori to ensure the best quality and cooling performance.