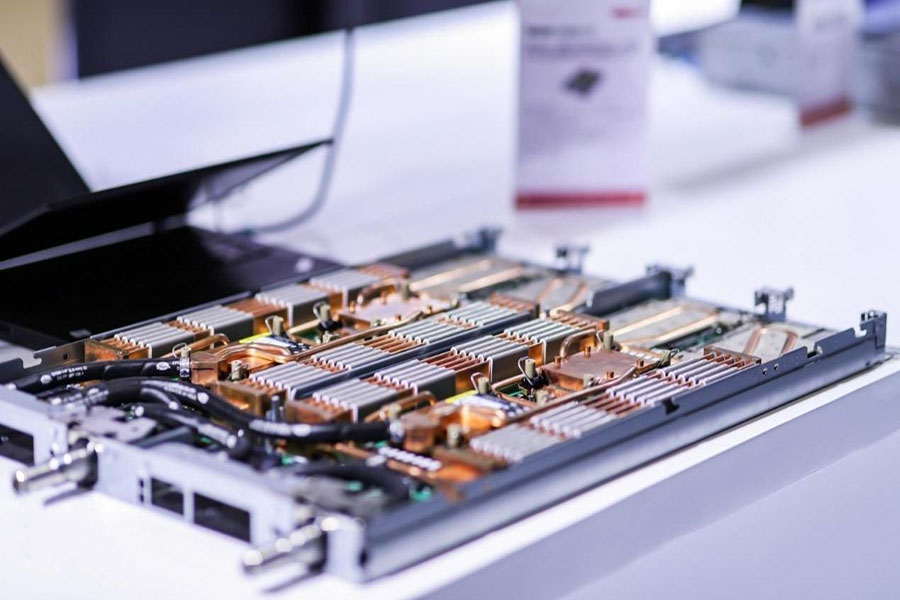

Lori Data Center liquid cooling system metal corrugated tubes are a key component designed to meet the demanding thermal management requirements of modern data centers. These flexible and durable tubes, made of high-grade stainless steel or other metal material, form the critical arteries of the liquid cooling circuit, efficiently transporting the coolant to the CPU, GPU, and other high-density heat-generating components, allowing them to directly absorb heat. By using our high-quality corrugated metal tubes, ensure that your infrastructure operates cooler, quieter, and more efficiently.

Core Product Advantages

1. Outstanding thermal conductivity

The data center liquid cooling metal tubes have excellent thermal conductivity, which ensures extremely low thermal resistance, thereby maximizing the efficiency of heat transfer between server components and the coolant.

2. Durable and reliable

They can withstand extremely high internal pressure and a wide operating temperature range, ensuring the integrity of the system under heavy load and fluctuating load conditions. They also have anti-corrosion, anti-permeation, and fire-resistant properties, adding a crucial layer of security to your data center.

3. Outstanding flexibility and ease of installation

The corrugated design offers high flexibility, enabling them to be easily routed and bent, thus adapting to complex and space-constrained server cabinet layouts. This simplifies the installation process and reduces labor costs.