As modern computing devices become increasingly powerful, the energy consumption of data centers, supercomputers, and servers continues to rise, making heat dissipation a critical issue. Traditional air cooling methods are proving inadequate for high-density computing needs, leading to the emergence of liquid cooling technologies. Liquid cooling primarily falls into two categories: Direct Liquid Cooling (DLC) and Immersion Cooling. While both methods use liquid to dissipate heat from equipment, their principles, applications, and advantages differ significantly.

Working Principles

Direct Liquid Cooling (DLC)

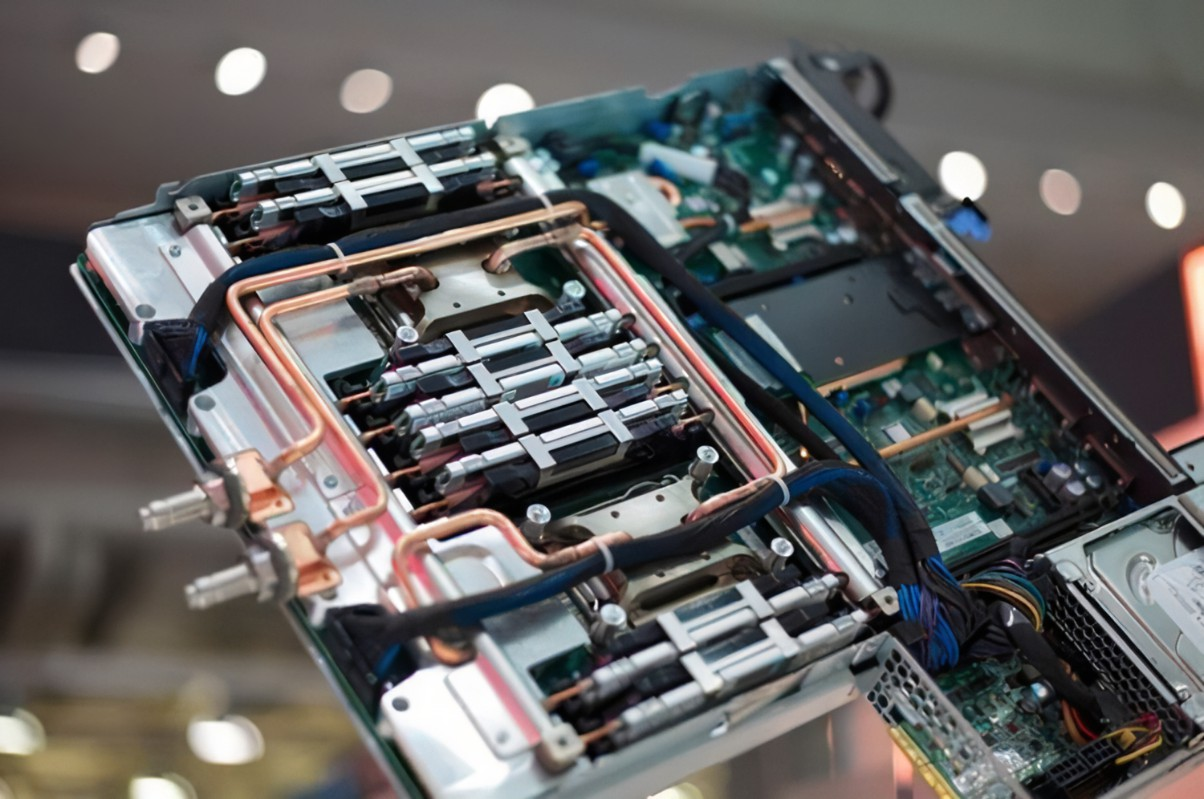

DLC involves installing liquid cooling plates or heat exchangers on key components (such as CPUs, GPUs, or power modules) within computing devices. Liquid circulates through these coolers, directly contacting heat-generating parts to remove heat. The coolant is typically transported through pipes to cooling devices and recirculated. This method enhances thermal management by combining liquid cooling with traditional air cooling, improving heat dissipation efficiency.

Immersion cooling involves completely submerging the entire computing device (such as a server) in a specialized insulating liquid. The liquid directly contacts all hardware, enabling comprehensive heat exchange. Since immersion liquids are usually non-conductive, they can safely interact with electronic components without damaging them. This approach eliminates the need for fans and other traditional air circulation systems.

1.Thermal Efficiency Comparison

DLC can target specific heat-generating components, allowing for efficient localized cooling. Compared to air cooling, liquid has better thermal conductivity, and DLC can effectively lower the temperature of core components in high-performance computing environments. While it provides a significant improvement over air cooling, it still requires consideration of overall system heat management, especially for parts not covered by liquid cooling.

Immersion cooling achieves exceptional thermal efficiency because the entire device is submerged in liquid, allowing for uniform heat distribution. This makes immersion cooling particularly effective in extreme high-temperature workloads, as it can manage thermal distribution more comprehensively than DLC. In high-power, high-density scenarios, immersion cooling typically outperforms direct liquid cooling.

2.System Complexity and Maintenance

DLC systems are relatively complex, requiring the installation and maintenance of liquid cooling pipes, cooling plates, pumps, and heat exchangers. Although the liquid does not directly contact all components, a highly sealed cooling system is necessary to prevent leaks. Regular maintenance can be intricate, and since DLC still relies on some air cooling, the overall layout requires careful design.

Immersion cooling systems tend to be simpler in structure, as they lack complex components like cooling pipes and heat sinks. However, they require careful selection and periodic replacement of the cooling liquid. Since all devices are submerged, maintenance involves removing and drying equipment, which can add to the workload. Unlike DLC, immersion cooling liquids may need to be replaced regularly, especially as they absorb heat over time or degrade with prolonged use.

3.Application Scenarios

DLC is suitable for environments that require efficient cooling without completely abandoning air cooling systems, particularly where precise cooling of critical components is necessary. This includes data centers and high-performance computing devices, especially those running intensive workloads, where DLC can help maintain stable temperatures and extend equipment lifespan.

Immersion cooling is ideal for higher power and density devices, particularly in extreme environments, such as large data centers or supercomputers requiring continuous, efficient cooling. For high-performance, always-on workloads (such as AI training or cryptocurrency mining), immersion cooling is particularly attractive due to its ability to significantly reduce energy consumption and cooling equipment footprint.

4.Energy Consumption and Cost

DLC can significantly lower energy consumption compared to air cooling, especially in handling high-power devices. While installation costs can be high,particularly for liquid cooling modules, the overall energy expenditure and operational costs tend to be lower during operation

Immersion cooling requires a higher initial investment, especially for the purchase of specialized cooling liquids and system setup. However, due to its exceptional cooling efficiency, it can lead to substantial energy savings in the long run. Additionally, the ability to increase equipment density can save space and reduce operational costs in data centers.

Conclusion

In comparing direct liquid cooling and immersion cooling, each has its own strengths. Direct liquid cooling excels in system complexity and targeted cooling, making it suitable for environments that require precise cooling while still utilizing some air cooling. In contrast, immersion cooling offers superior thermal efficiency and energy optimization, especially for high-density, high-power applications. Ultimately, the choice should depend on specific application needs, system power consumption, and long-term cost considerations.