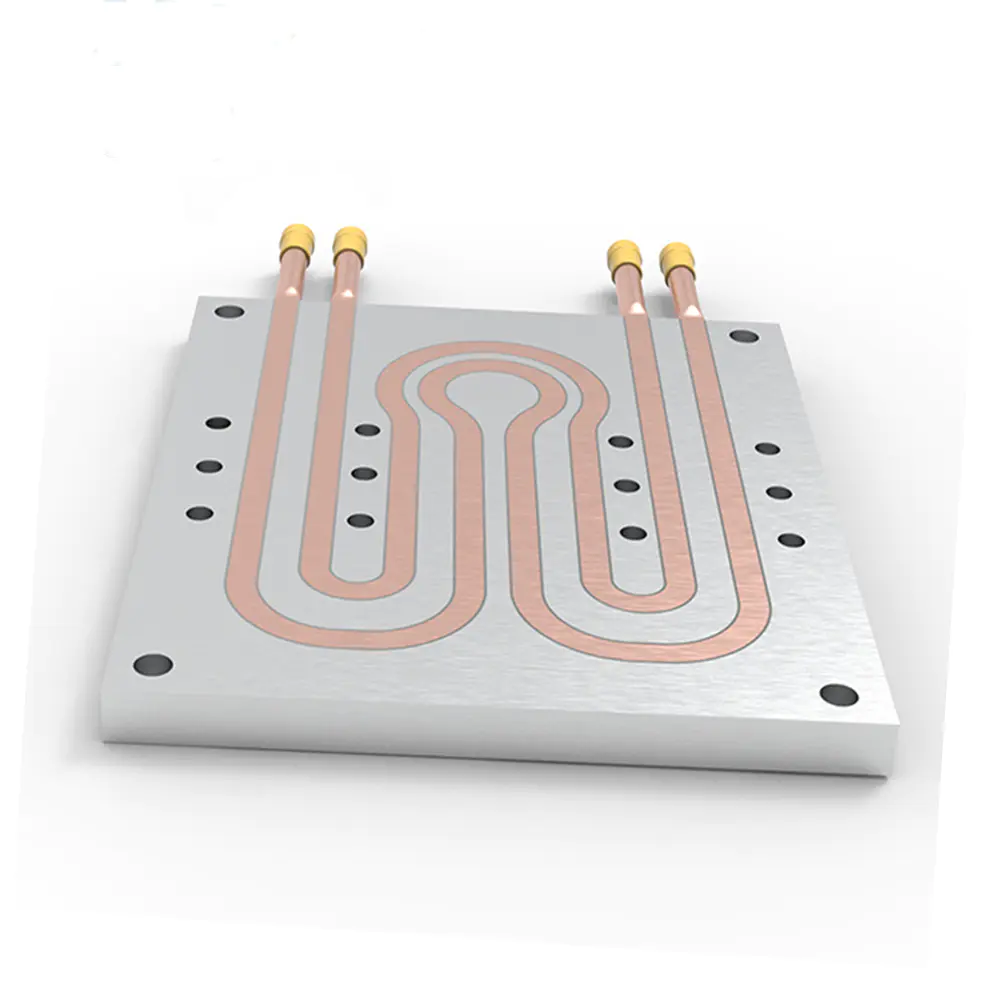

Lori custom liquid cooling plates are specifically engineered to meet the thermal management demands of modern electric vehicle battery packs. Crafted from premium aluminum with an innovative microchannel design and employing a side cooling approach, our plates deliver unparalleled heat dissipation. This ensures your batteries operate within the ideal temperature range, achieving optimal performance and long-term reliability.

Battery Pack Cold Plate Advantages

1. Microchannel Design for Superior Heat Dissipation

The microchannel structure significantly increases the surface area exposed to coolant, enabling rapid and efficient heat extraction from battery cells. This prevents hotspots and ensures uniform temperature distribution throughout the battery module, extending battery lifespan.

2. Lightweight and Robust Aluminum Construction

Crafted from high-strength, corrosion-resistant aluminum alloy, the microchannel cold plate delivers an outstanding strength-to-weight ratio. This enhances overall vehicle efficiency without compromising structural integrity or durability. Aluminum's superior thermal conductivity ensures optimal heat transfer.

3. Customizable to Meet Your Unique Requirements

We offer comprehensive customization services for dimensions, shapes, channel layouts, and interface connections. This ensures perfect adaptation to your specific battery architecture and delivers optimal thermal performance for passenger electric vehicles, commercial vehicles, or energy storage systems (ESS).

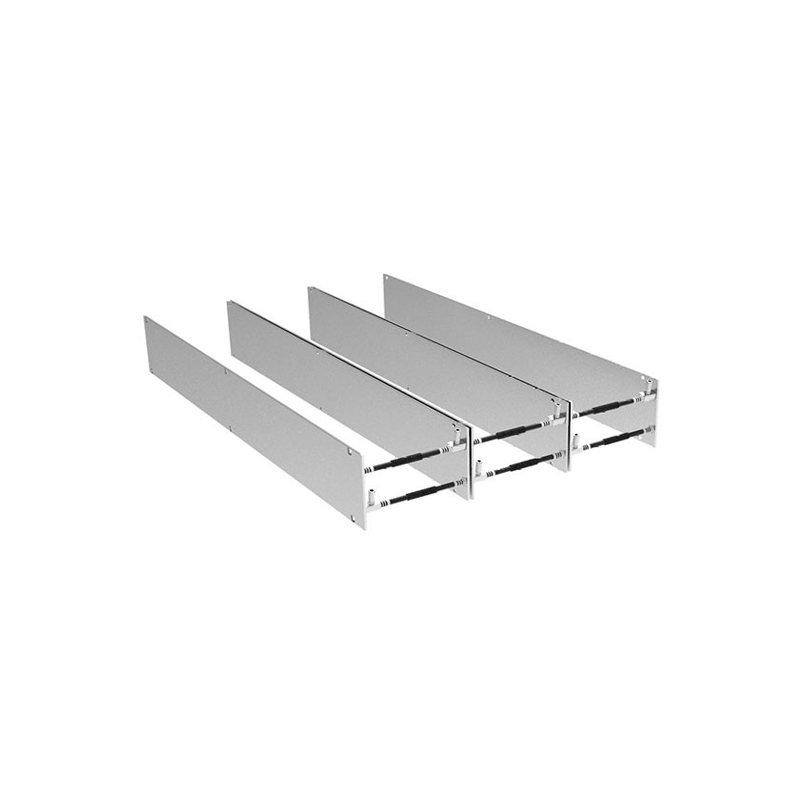

4. Efficient Side-Contact Heat Dissipation

This design enables direct contact with the sides of prismatic or pouch battery cells, providing a large, highly efficient heat dissipation surface. It maximizes thermal transfer efficiency within a compact footprint, making it ideal for space-constrained battery packs.

5. Rugged Durability and Leak-Proof Performance

Utilizing advanced welding and sealing techniques, it withstands high pressure and harsh operating environments, ensuring long-term, maintenance-free reliability while protecting your valuable battery components.