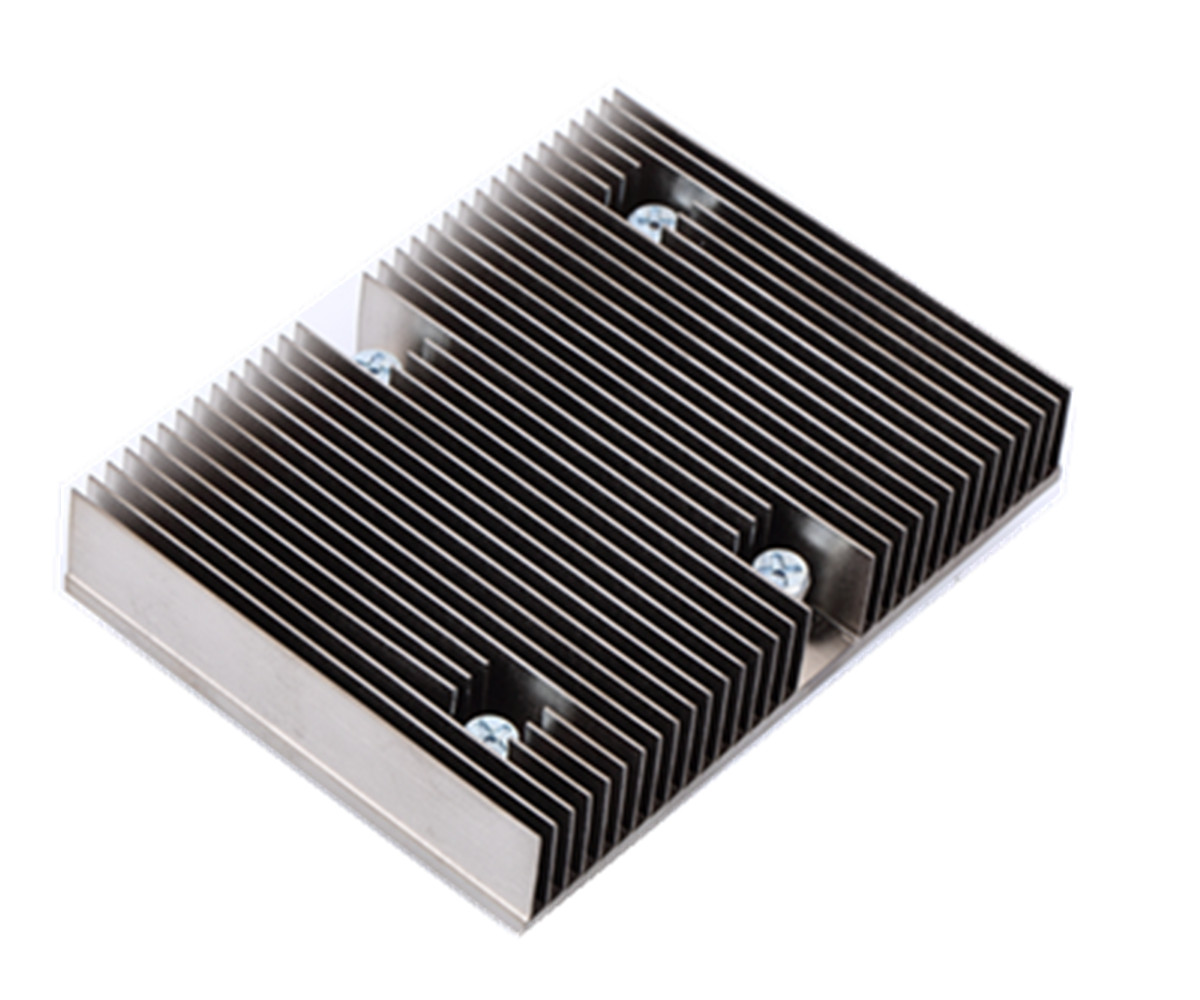

Aluminum Skiving fin heatsink

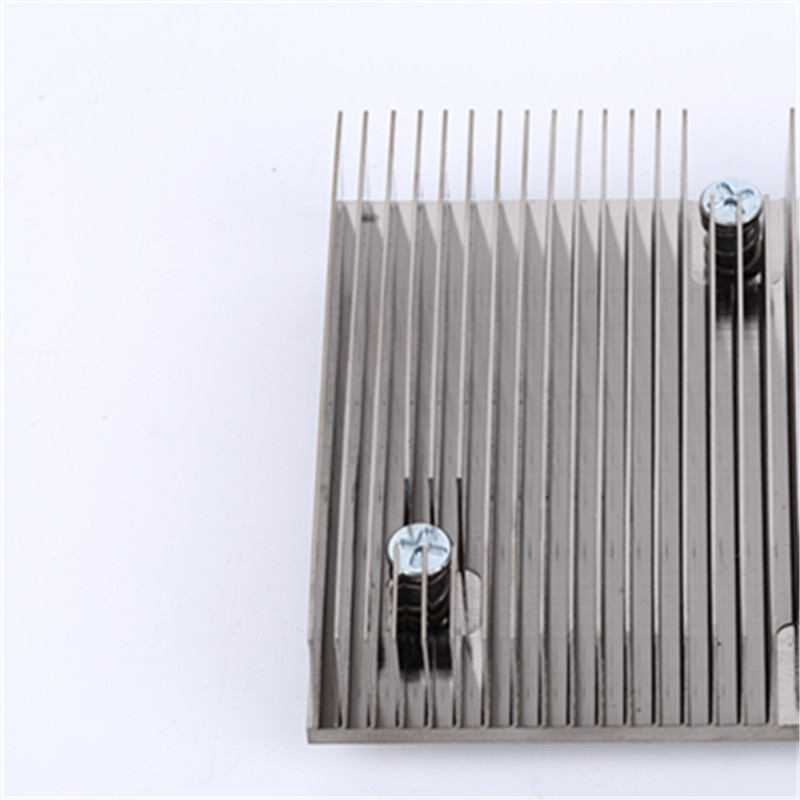

Skiving fin heatsink can be an alternative to aluminum extruded heat sink, because skiving heatsink with fin desity and thin fin,which can’t be achieved by aluminum extrusion technology.

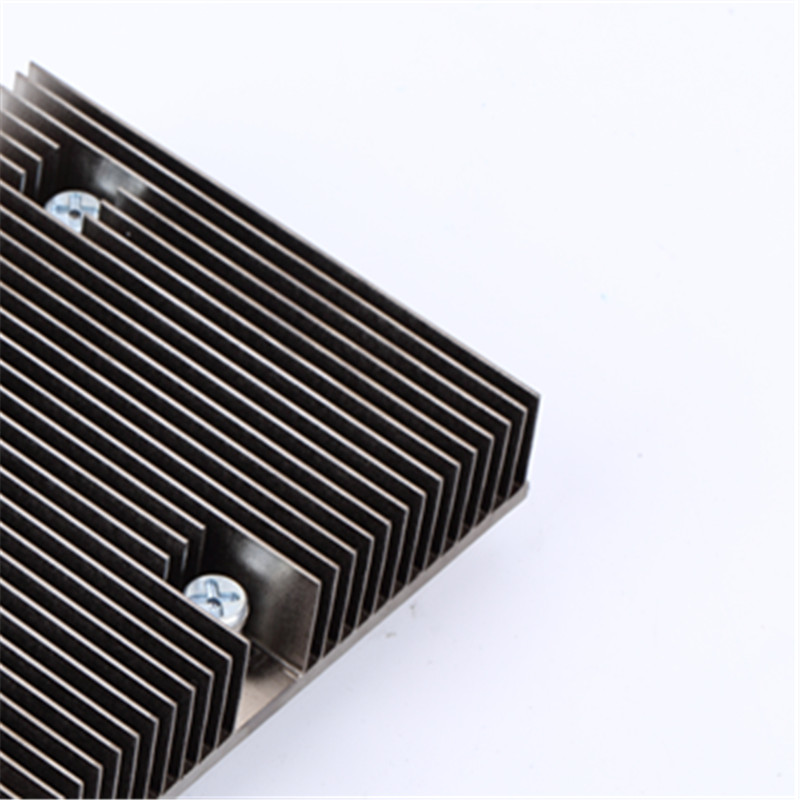

This aluminum skiving fin heatsink fabrication does not need expensive mold, can saves on mold cost and design flexibility. Also when we cutting fin, we can use the same tool which save factory cost on tooling cost. Besides, skived heat sinks are made of pure aluminum, thermal conductivity is good than the aluminum alloy, and the base and fins are one piece, so the heat dissipation performance is more stable. and the skiving heat sink size is 200*150*40mm , use for led light.

Lori's skiving fin leading the heat innovation innovation high density ,high performance, high aspect ratio, excellent performance.